Replacement method for water outlet pipelines of high-pressure ammonia water pump of coking furnace

A technology of high-pressure ammonia water and outlet pipelines, applied in the field of coking, can solve problems such as increased production costs, affecting normal production, and shutdown of coke ovens, and achieves the effect of stable replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment the embodiment of the present invention is further described:

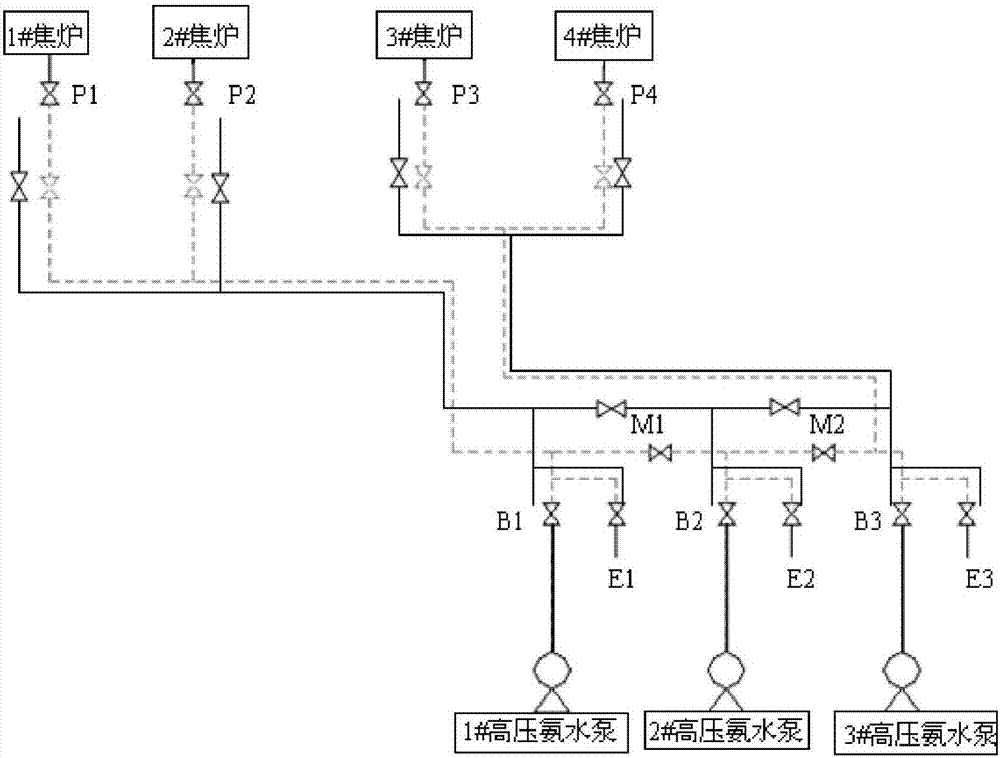

[0023] See figure 1 , the dotted line part is the part of the old pipe that needs to be replaced, and the solid line part is the new pipe.

[0024] A method for replacing the outlet pipeline of a coke oven high-pressure ammonia water pump. A new pipeline is laid in advance along the old pipeline route, and joint operations between the new pipeline and the valve are carried out respectively during coke oven maintenance time, so as to realize non-stop replacement of the high-pressure ammonia water pipeline.

[0025] The specific method steps are as follows:

[0026] 1) Lay all the new pipelines along the laying route of the old pipelines to be replaced, and install all the control valves connected to the pipelines. At the same time, make preparations before the joint: a) pre-thread all the flange bolts that need to be jointed. b) Lay tight asbestos around all p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com