Fermented mulberry juice and making method thereof

A technology of mulberry juice, inoculation and fermentation, applied in the direction of bacteria, bifidobacteria, and food ingredients used in food preparation, can solve the problems of difficulty in industrial production, complex production process, complex formula, etc., and achieve the expansion of sales radius, The effect of simple production process and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a kind of preparation method of fermented mulberry juice, and this method may comprise the following steps:

[0033] S1: Mix mulberry raw juice, reducing sugar and water evenly, then filter and sterilize to obtain a mixed solution.

[0034] S2: inoculate the starter when the mixed solution is cooled to a preset temperature, and ferment at the preset temperature to obtain fermented mulberry juice.

[0035] In order to preserve the fermented mulberry juice conveniently and effectively, the preparation method further comprises:

[0036] S3: Homogenizing the fermented mulberry juice.

[0037] The above-mentioned labels of S1, S2, and S3 and the specific steps in the labels are not used to limit the order of each step in the preparation method, and the order of each step in the method can be changed as long as it is logically reasonable.

[0038] The above-mentioned starter includes but not limited to probiotics. Probiotics...

Embodiment 1

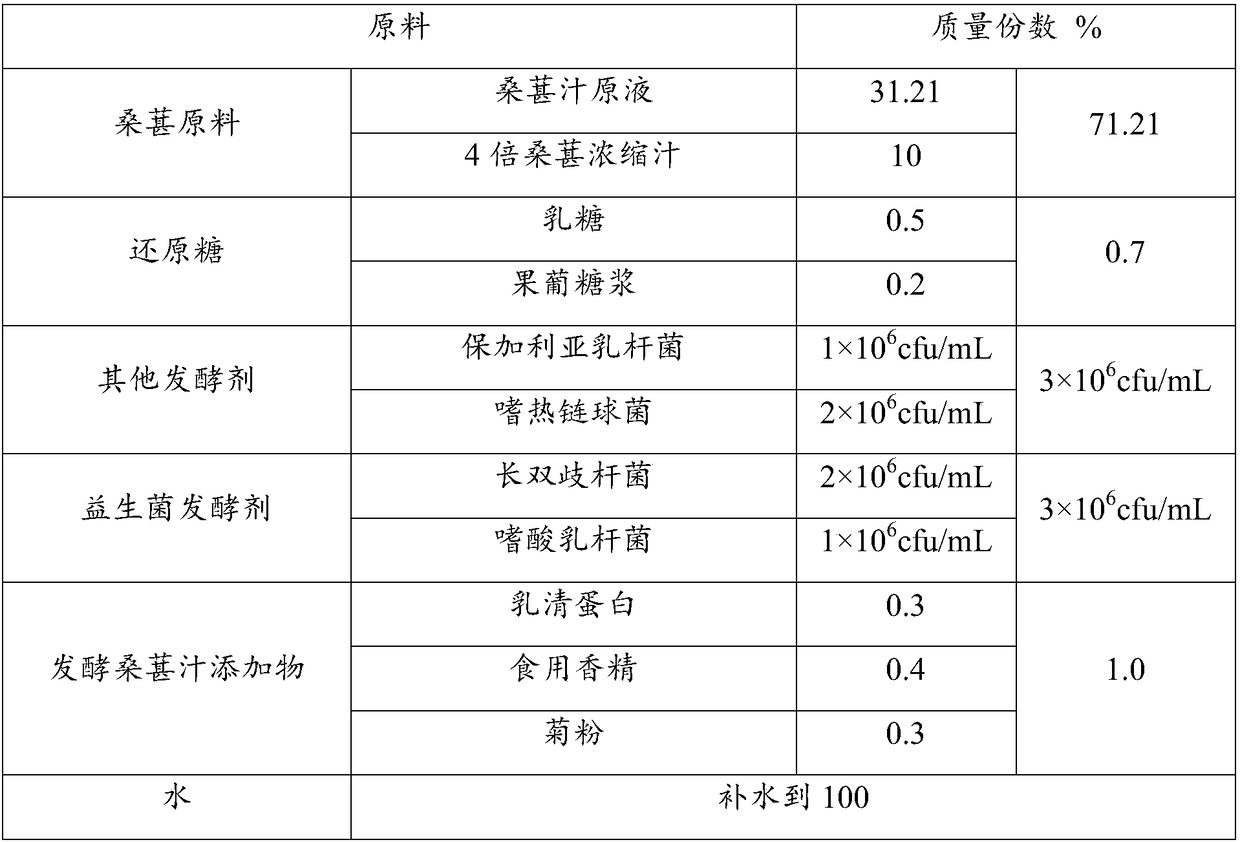

[0060] 1. Proportion

[0061] Table 1

[0062]

[0063] 2. Method

[0064] (1) Stir and mix mulberry raw material, reducing sugar and water according to the proportioning in Table 1 at 20°C for 30 minutes, filter, and sterilize at 90°C for 5 minutes to obtain a mixed solution, wherein the content of mulberry juice is 40%;

[0065] (2) Cool the mixed solution to 25° C., add a starter according to the ratio in Table 1, and ferment at 25° C., stop the fermentation after 96 hours, and obtain fermented mulberry juice;

[0066] (3) The fermented mulberry juice is homogenized at 54°C, 15Mpa, sterilized at 85°C for 300s, cooled to 4°C, filled, and can be transported and stored at room temperature.

[0067] After testing, no mold, yeast, Escherichia coli, and pathogenic bacteria were detected after 12 months of storage; the obtained product was used for taste evaluation.

Embodiment 2

[0069] 1. Proportion

[0070] Table 2

[0071]

[0072] 2. Method

[0073] (1) Stir and mix mulberry raw material, reducing sugar and water according to the proportioning in Table 2 at 30°C for 28 minutes, filter, and sterilize at 91°C for 5 minutes to obtain a mixed solution, wherein the content of mulberry juice is 50%;

[0074] (2) Cool the mixed solution to 26° C., add the starter according to the ratio in Table 2, and ferment at 26° C., stop the fermentation after 90 hours, and obtain fermented mulberry juice;

[0075] (3) The fermented mulberry juice is refined by an emulsification pump, cooled to 15°C, filled, transported and stored at 10°C.

[0076] After testing, after 2 months of placement, the number of lactic acid bacteria is 7*10 7 cfu / mL, mold, yeast, Escherichia coli, and pathogenic bacteria meet the microbial limit of the national standard for beverages; the obtained products are used for taste evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com