Deep ultraviolet LED packaging structure and preparation method thereof

A technology of LED packaging and deep ultraviolet, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of detachment of the cover plate and the substrate, and achieve the effects of improving sealing, improving bonding force, and reducing light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

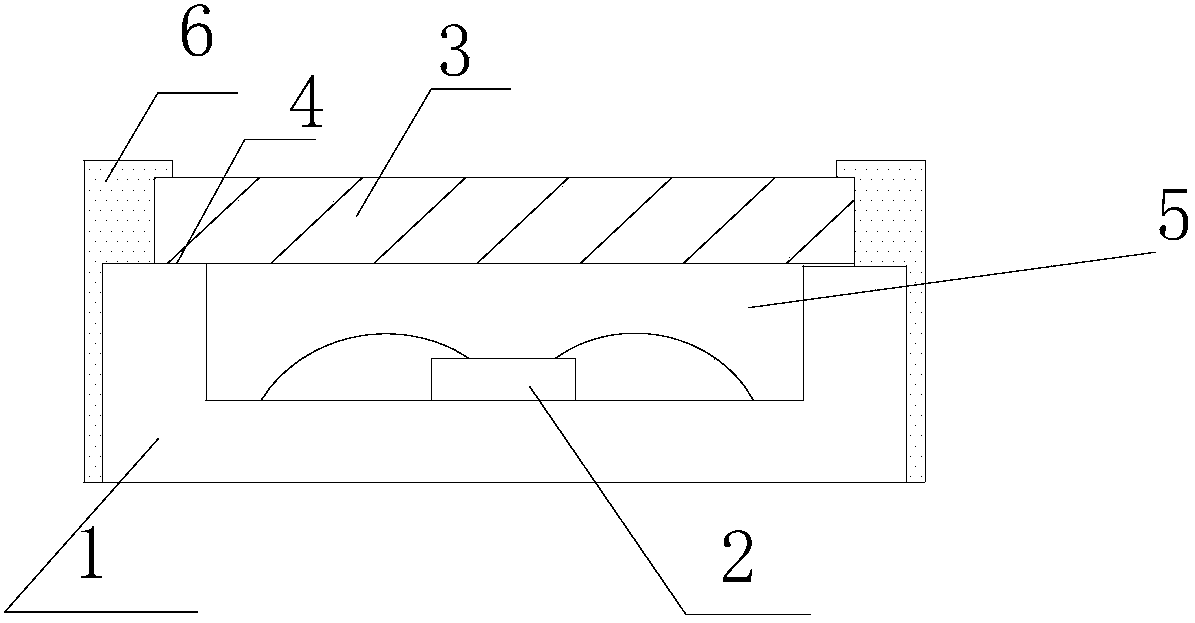

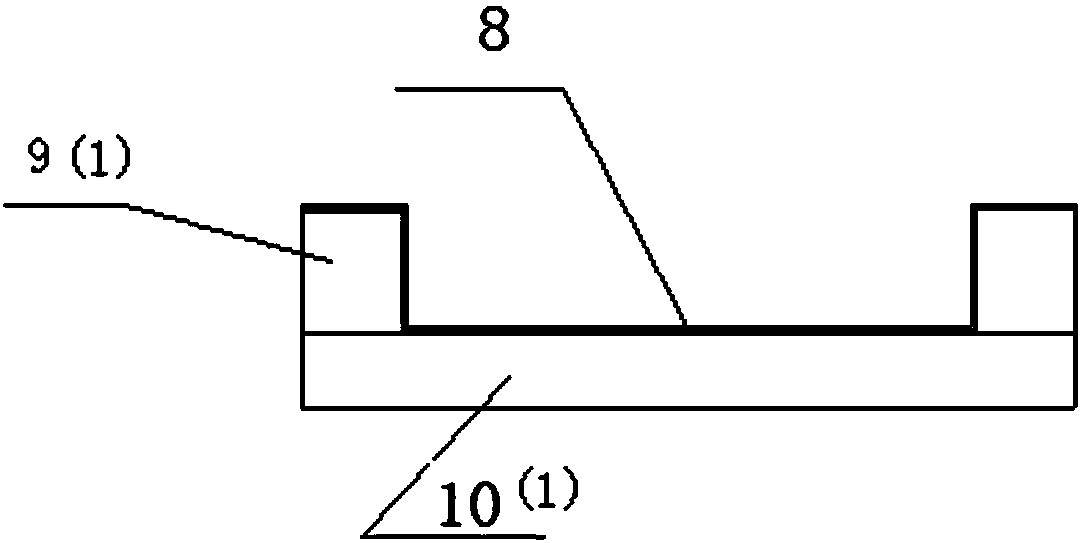

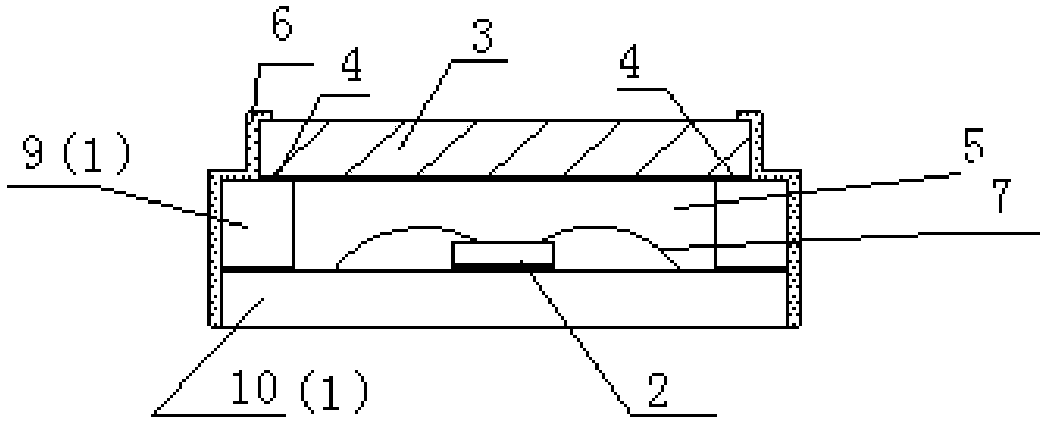

[0040] In one embodiment of the present invention, as figure 1 As shown, an ultraviolet LED packaging structure is provided, including a ceramic support 1 , an ultraviolet or deep ultraviolet LED chip 2 , quartz glass 3 and a metal coating 6 . The ceramic support 1 has a cup structure and is integrally formed with high thermal conductivity; the ultraviolet or deep ultraviolet LED chip 2 is mounted inside the ceramic support 1 by means of silver glue or soldering, and the ultraviolet or deep ultraviolet LED chip 2 The positive and negative poles are respectively fixed on the bottom surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com