A wire grid unit and its protection device

A protection device, the technology of the first wire grid, applied in polarizing elements, optical elements, nonlinear optics, etc., can solve the problems of difficult processing of wire grid splicing devices, easily deformed splicing gaps, etc., to increase the effective light transmission area, improve Cumulative dose uniformity, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

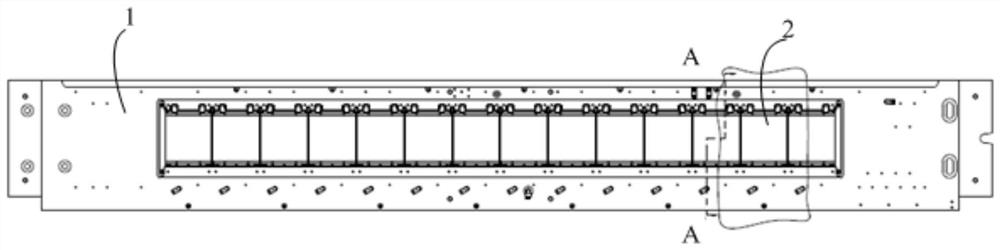

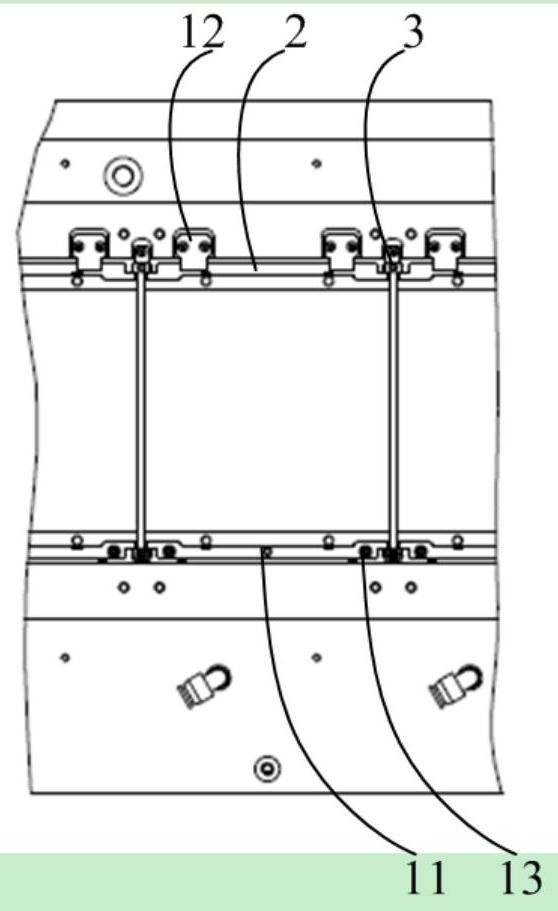

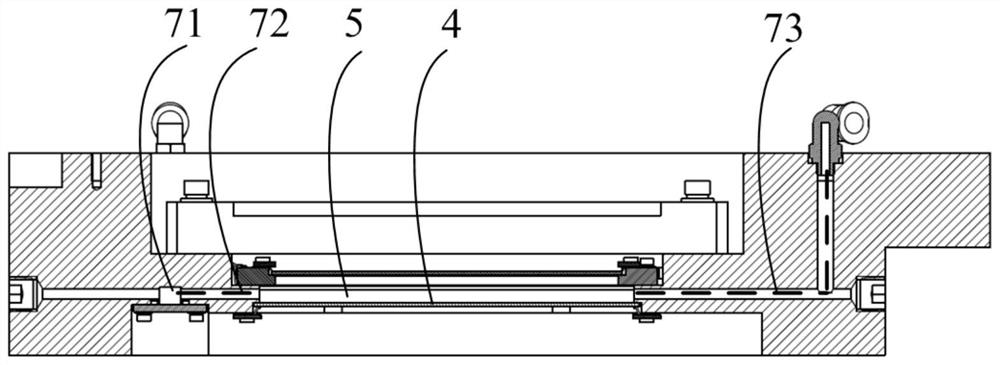

[0060] See Figure 1~3 ,among them, figure 2 Yes figure 1 A partial enlarged view of a single wire grid unit in image 3 It is a cross-sectional view from the A-A direction. An open wire grid splicing protection device includes a frame 1, a plurality of wire grid units 2, a frame light-blocking strip 3, a sealing element 4 and a gas path system. The wire grid unit 2 is in a straight shape They are arranged on the frame 1. In this embodiment, fourteen of the wire grid units 2 are arranged, and the frame light-blocking strips 3 are located under the splicing seams between the wire grid units 2 and are arranged at all On the frame 1, the frame light blocking strip 3 is not in contact with the wire grid unit 2, the width of the frame light blocking strip 3 is not less than the width of the splicing seam, and the sealing member 4 is arranged on the The frame 1 forms an integrated chamber 5 with the frame 1, the frame light-blocking strip 3 and the wire grid unit 2, and the gas path ...

Embodiment 2

[0074] See Figure 6 ~ Figure 10 The difference between the second embodiment and the first embodiment is that one end of the wire grid unit 2 locates the first wire grid support 22 through the positioning pin 11 provided on the frame 1, and is supported by the first wire grid The pressing nails 14 on the member 22 and the second wire grid supporting member 23 press the wire grid unit 2 to position the wire grid unit 2 on the frame 1, and the pressing nail 14 can fix the wire Location of gate unit 2. In this embodiment, there are three compression pins 14, and the center of the figure formed by the positioning pins 11 and the three compression pins 14 coincides with the projection of the center of gravity of the wire grid 21 on the scale surface of the wire grid. . The second wire grid support 23 is provided with a shift lever 15 corresponding to the position of the positioning pin 11, and the wire grid 21 is adjusted in-plane rotation through the shift lever 15.

[0075] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com