A flexible optical fiber image transmission bundle with high resolution and low broken wire rate and its acid-soluble preparation method

An optical fiber image beam, high-resolution technology, applied in the direction of beam optical fiber, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of monofilament uniformity and light transmittance discount, light transmittance performance influence, cladding bonding, etc. The problem is to shorten the acid dissolution time, increase the effective light-passing area, and increase the cross-section effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] (1) Preparation of optical fiber monofilament

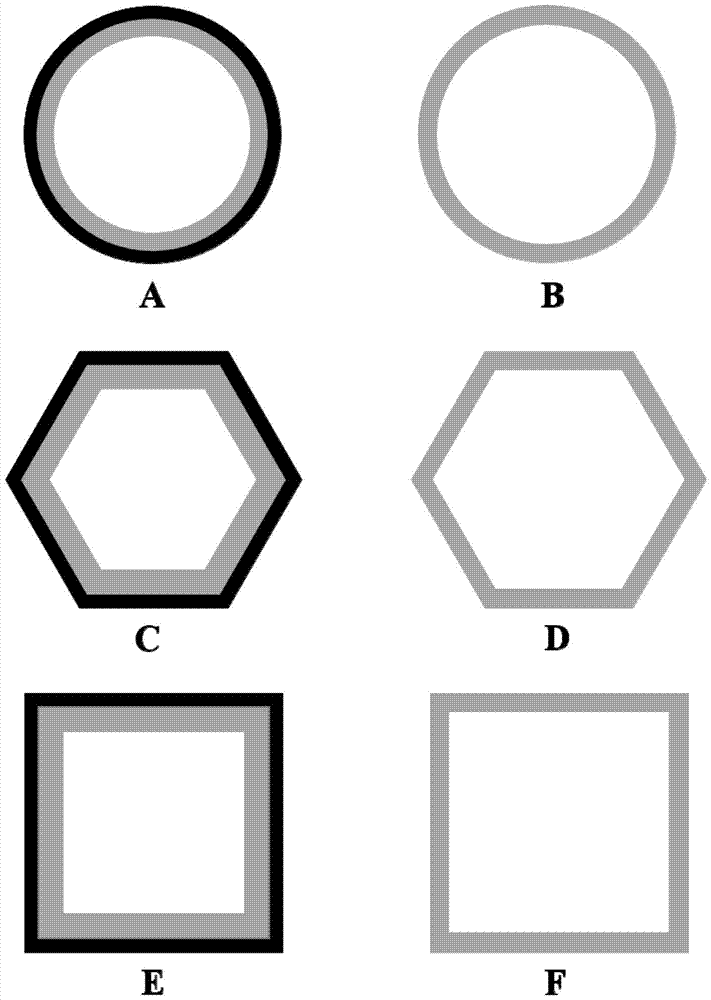

[0025] Optical fiber monofilaments are drawn by the tube rod method, and there are two types. One is a double-clad optical fiber monofilament with an acid-soluble glass outer cladding (acid-soluble glass-clad optical fiber monofilament), and the other is a single-clad optical fiber monofilament. The cross-section and core cross-section of optical fiber monofilament are generally circular or regular hexagonal (such as figure 2 ), it can also be a square or other regular polygons, and the diameter of the monofilament is generally 0.1-1mm.

[0026] The acid-soluble glass layer in the acid-soluble glass-clad fiber monofilament is a transition medium, which is dissolved in the acid-dissolving process, and the monofilament is separated, so that the image-transmitting bundle is transformed from rigid to flexible, and finally only in the image-transmitting bundle. The ends of the bundles retain the acid soluble layer, the purpo...

Embodiment 1

[0039] (1) Using the tube rod method, the 32mm (inscribed circle diameter) mandrel, 2mm thick cladding glass casing and 2mm thick acid-soluble glass layer casing with regular hexagonal cross-sections are drawn into an inscribed circle with a diameter of 100μm (core diameter 80μm, cladding diameter 5μm, acid soluble cladding diameter 5μm) acid-soluble glass-clad fiber monofilament.

[0040] (2) Using the tube-and-rod method, a core rod with a diameter of 36 mm (inscribed circle) and a 2 mm thick cladding glass sleeve are drawn into a diameter of an inscribed circle of 100 μm (the core diameter is 90 μm, and the cladding Single-clad optical fiber monofilament with a thickness of 5 μm).

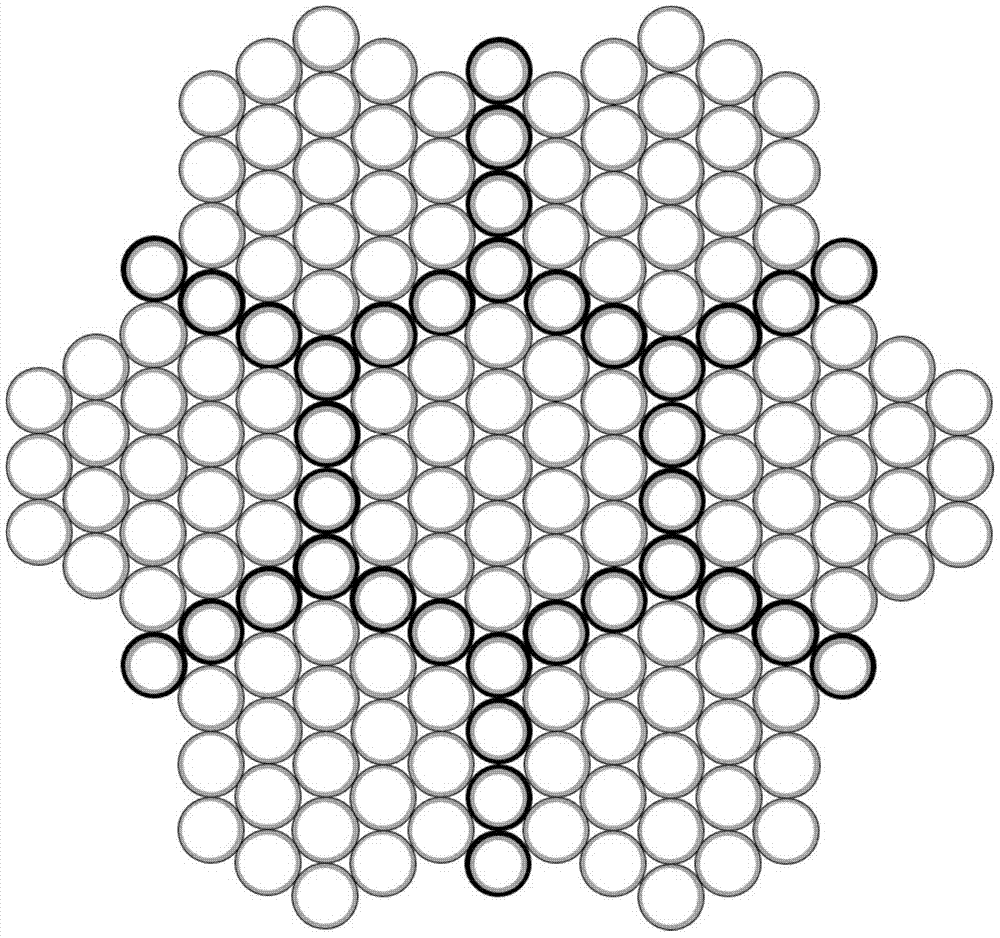

[0041] (3) Take 145,000 optical fiber monofilaments with a regular hexagonal cross-section with a length of 600 mm, including 43,000 acid-soluble glass-clad optical fiber monofilaments. Use acid-soluble glass-clad optical fiber monofilaments to separate the regular hexagonal array units formed ...

Embodiment 2

[0045] (1) Using the tube rod method, the 32mm (inscribed circle) diameter core rod, 2mm thick cladding glass casing and 2mm thick acid-soluble glass layer casing with regular hexagonal cross-sections are drawn into an inscribed circle with a diameter of 900μm (core diameter 720μm, cladding diameter 45μm, acid soluble cladding diameter 45μm) acid soluble glass cladding fiber monofilament.

[0046] (2) Using the tube-and-rod method, a core rod with a diameter of 36 mm (inscribed circle) with a regular hexagonal cross-section and a 2 mm thick cladding glass sleeve are drawn into an inscribed circle with a diameter of 900 μm (core diameter 810 μm, cladding thickness 45μm) single-clad fiber monofilament.

[0047] (3) Take 721 optical fiber monofilaments with a regular hexagonal cross-section and a length of 600 mm, including 216 acid-soluble glass-clad optical fiber monofilaments. A regular hexagonal array unit formed by densely packing 19 single-clad optical fiber monofilaments ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com