A kind of different-diameter bamboo winding pipe structure and preparation method thereof

A winding tube and different-diameter technology, applied in the structure and preparation of different-diameter bamboo winding tubes, can solve the problems of easy cracking at the joint, low processing efficiency, and easy water leakage, etc., and achieve high tube-making efficiency, low strength, and not easy to break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The invention also provides a method for preparing a novel bamboo winding pipe, which includes the following steps:

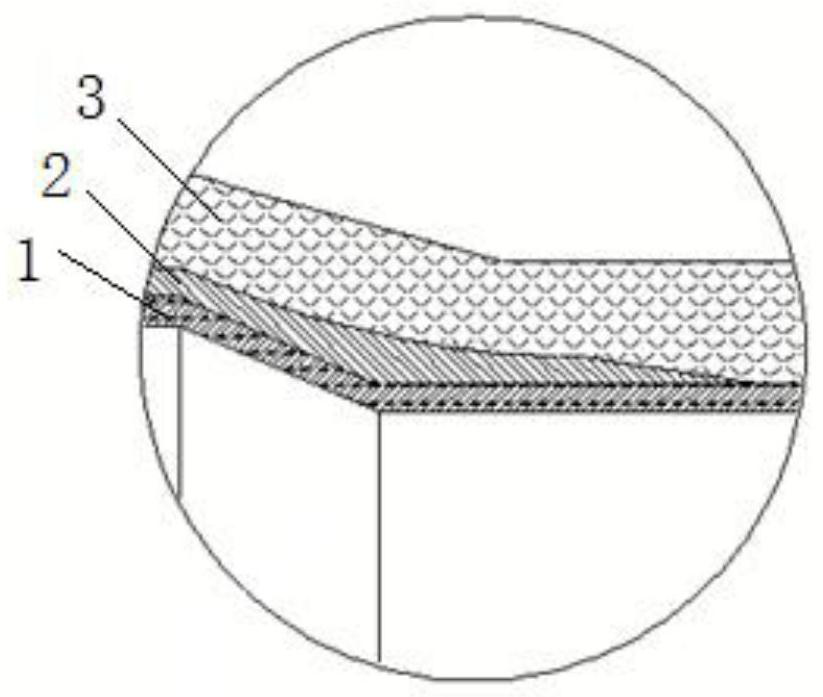

[0052] (1) First, fabric and adhesive are used to make an anti-corrosion and anti-seepage lining layer on the mold;

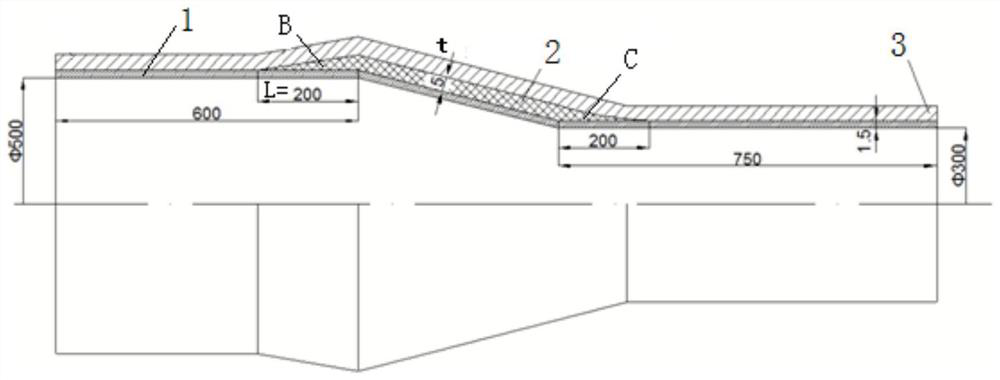

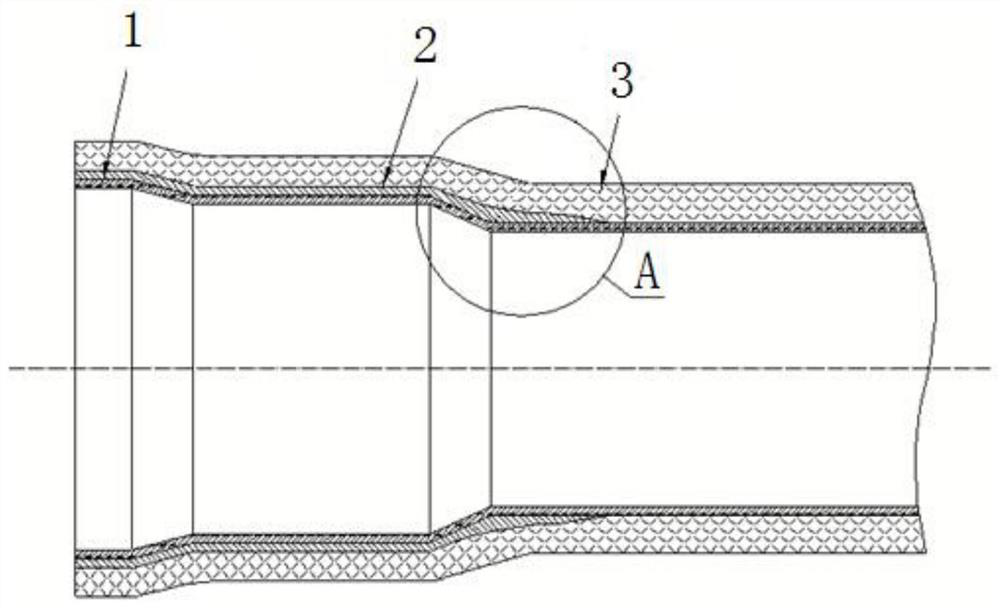

[0053] (2) Then, after preparing the inner lining layer, prepare the fiber reinforced layer: according to the formula Calculate the thickness t of the fiber reinforced layer; according to the nominal diameter of the large diameter end, determine the distance L from both ends of the fiber reinforced layer to the large diameter end and the small diameter end; according to the thickness t and length L, determine the thickness of the fiber reinforced layer away from The decreasing amount s in the direction of the tapered transition surface; according to the thickness t, length L and decreasing amount s, the high-strength fiber is impregnated with resin and then wound on the inner lining layer to obtain a fiber reinforced layer;

[0054] (3) Finally...

Embodiment 1

[0059] In this embodiment, the nominal diameter is DN300-DN500mm, the nominal pressure is 1.0MPa, and the stiffness grade is 10000N / m. 2 As an example, the method for preparing the reducing bamboo winding pipe structure of the present invention is specifically described. The specific steps are as follows:

[0060] 1) Bamboo fiber pretreatment:

[0061] Cut the fresh bamboo into bamboo slices, cut the bamboo slices to 1.5m long, 1mm thick, and 5mm wide after removing the blue and yellow. The bamboo sticks are dried, and then 10 bamboo sticks are arranged in parallel into a row. , The back of the entire row of bamboo strips is lined with a grid cloth and stitched with a sewing machine to form bamboo curtains. The head and tail of each row of bamboo curtains are butted and stitched with a sewing machine to form an uninterrupted strip of several meters or even more than tens of meters. The bamboo curtain belt is rolled up to obtain the bamboo roll for use.

[0062] 2) Preparation of inn...

Embodiment 2

[0071] In this embodiment, the nominal diameter is DN1800mm, the nominal pressure is 1.0MPa, and the stiffness grade is 10000N / m. 2 Take the bamboo-wound composite pipe socket as an example to illustrate the preparation method of the reduced-diameter bamboo-wound pipe structure of the present invention. The specific steps are as follows:

[0072] 1) Bamboo fiber pretreatment:

[0073] Cut the fresh bamboo into bamboo slices, cut the bamboo slices into 2m long, 1.2mm thick, and 4mm wide bamboo strips after removing the blue and yellow. The bamboo strips are dried, and then 12 bamboo strips are arranged in parallel and neatly arranged in a row , The back of the entire row of bamboo strips is lined with a grid cloth and stitched with a sewing machine to form bamboo curtains. The head and tail of each row of bamboo curtains are butted and stitched with a sewing machine to form an uninterrupted strip of several meters or even more than tens of meters. The bamboo curtain belt is rolled u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com