Nano chemical plating and preparing method and application thereof

An electroless plating and electroless plating technology, applied in liquid electroless plating, coating, heat exchange equipment and other directions, can solve the problems of reducing the anti-scaling function of heat exchangers, lack of anti-scaling ability of the coating, easy to fall off of the coating, etc. The effect of reducing heat transfer thermal resistance, reducing size, and small excess thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

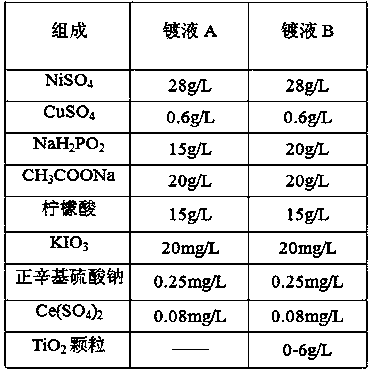

Embodiment 1

[0053] Prepare the electroless coating as follows:

[0054] (1) Use a DN25×100 copper tube as the material, polish its surface with 400, 800, and 1200 mesh sandpaper in sequence to remove oxides on the surface of the copper tube, wash it with water, and immerse the copper tube in an alkaline solution for 30 minutes to remove oil , keep the temperature of the lye at about 75°C, wash it with water, and then put the copper tube into 10% H 2 SO 4 Activated in the solution for 30s, washed again with water to obtain the base layer.

[0055] Wherein, the composition of described alkali solution is: NaOH 20g / L, NaOH 2 CO 3 23g / L, Na 3 PO 4 35g / L, OP-105mol / L.

[0056] (2) Prepare each plating solution according to the composition in Table 1

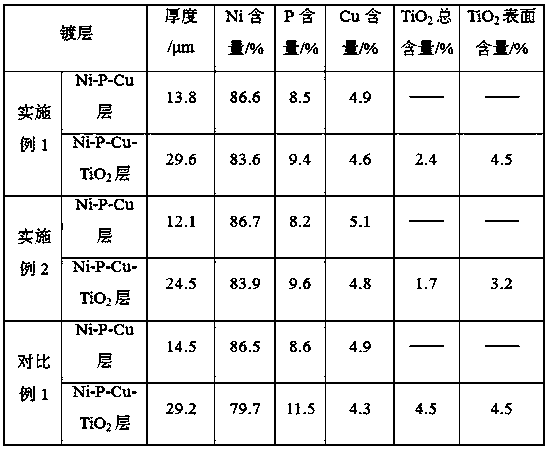

[0057] Table 1

[0058]

[0059] Among them, TiO in bath B 2 It is an anatase structure particle with a particle size of 10-20nm. Weigh the required TiO 2 The total amount was added to the dispersant prepared by n-octyl sodium sul...

Embodiment 2

[0062] (1) Using 30×30×1.5 45# stainless steel plate as material, the operation of surface treatment is the same as step (1) in Example 1.

[0063] (2) Prepare each plating solution according to the composition in Table 2

[0064] Table 2

[0065]

[0066] Among them, TiO in bath B 2 It is an anatase structure particle with a particle size of 10-20nm. Weigh the required TiO 2 The total amount was added to the dispersant prepared by n-octyl sodium sulfate and absolute ethanol for ultrasonic dispersion for 10 minutes to obtain TiO 2 suspension.

[0067] (3) Dip the treated substrate into plating solution A and plating solution B in sequence to perform electroless plating. The plating time is 20 minutes and 45 minutes respectively, and the plating temperature is kept at 75-80°C and the pH is 4.2. After the plating is completed, it is washed with water and dried. Get substrate layer / Ni-P-Cu layer / Ni-P-Cu-TiO 2 Nano-electroless coatings arranged in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com