Concentration method for salt-containing wastewater and recycling method for salt-containing wastewater

A technology of salty wastewater and treatment methods, which is applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as high cost, ineffective integration of functions, and inability to achieve zero discharge, etc., to achieve Low cost, long operation cycle, and the effect of improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the salt-tolerant de-COD denitrification microbial bacterial agent of (3) of the present invention comprises the following contents:

[0046] (1) Paracoccus FSTB-2, Microbacterium kitami FSTB-4 and Pseudomonas stutzeri FSTB-5 were inoculated on FSTB solid medium for activation; SDN-3 was respectively inoculated on the corresponding solid medium for activation;

[0047] (2) Use the inoculation loop to inoculate the colonies of Paracoccus FSTB-2, Kitamibacterium FSTB-4 and Pseudomonas stutzeri FSTB-5 on the plate into the corresponding FSTB liquid culture medium respectively, and use the inoculation loop to Take the colonies of Paracoccus denitrificans DN-3 and Methylobacterium SDN-3 on the plate and inoculate them in the corresponding liquid culture medium respectively, and cultivate them for 24-72 hours at a temperature of 20-40°C and 150-240rpm until logarithmic growth period, to obtain liquid bacterial agent seed liquid;

[0048] (3) After ...

Embodiment 1

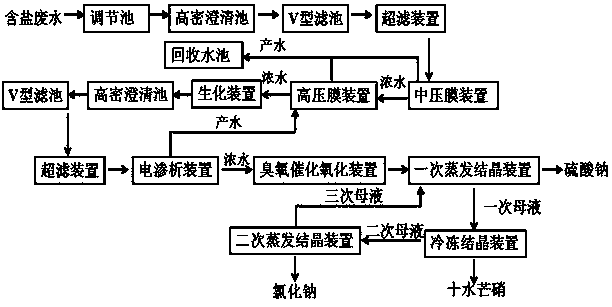

[0052] The average concentration of each pollutant in a high-salt industrial wastewater is: COD is 75 mg / L, total hardness (as CaCO 3 Calculated) is 1000mg / L, total alkalinity (as CaCO 3 (calculated) is 400 mg / L, silicon dioxide is 30 mg / L, and TDS is 5000 mg / L, among which, the concentration of nitrate ion is 70 mg / L, the concentration of chloride ion is 700 mg / L, and the concentration of sulfate ion is 1000 mg / L, the pH value is 7.8. Such as figure 1 As shown, using the zero-discharge treatment process for coal chemical industry saline wastewater includes the following steps:

[0053] (1) Salt-containing wastewater enters the high-density clarification tank. According to the water quality of the saline wastewater, 1.8g / L of calcium hydroxide is added to the reaction zone of the high-density clarification tank to maintain the pH value at 11.0-11.5, and then add 2.4 g / L sodium carbonate, then add 50 mg / L PFS for coagulation and 4 mg / L PAM to aid coagulation. After fully c...

Embodiment 2

[0062] The average concentration of each pollutant in a high-salt industrial wastewater is: COD is 78 mg / L, total hardness (calculated as CaCO 3 Calculated) is 1200mg / L, total alkalinity (as CaCO 3 (calculated) is 500 mg / L, silicon dioxide is 30 mg / L, and TDS is 5500 mg / L, among which, the concentration of nitrate ion is 80 mg / L, the concentration of chloride ion is 700 mg / L, and the concentration of sulfate ion is 1500 mg / L mg / L, the pH value is 7.8.

[0063] Such as figure 1 As shown, using the zero-discharge treatment process for coal chemical industry saline wastewater includes the following steps:

[0064] (1) The saline wastewater enters the high-density clarification tank. According to the water quality of the saline wastewater, 2.0g / L sodium hydroxide is added to the reaction area of the high-density clarification tank to maintain the pH value at 11.0-11.5, and then add 2.5 g / L sodium carbonate, then add 100 mg / L PFS for coagulation and 10 mg / L PAM to aid coagul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Turbidity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com