Device and method for one-step mass production of graphene by electrochemical process

An electrochemical and graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of high risk factor, low efficiency, and long time consumption, and achieve the effect of low energy consumption, short time consumption, and reduction of environmental pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

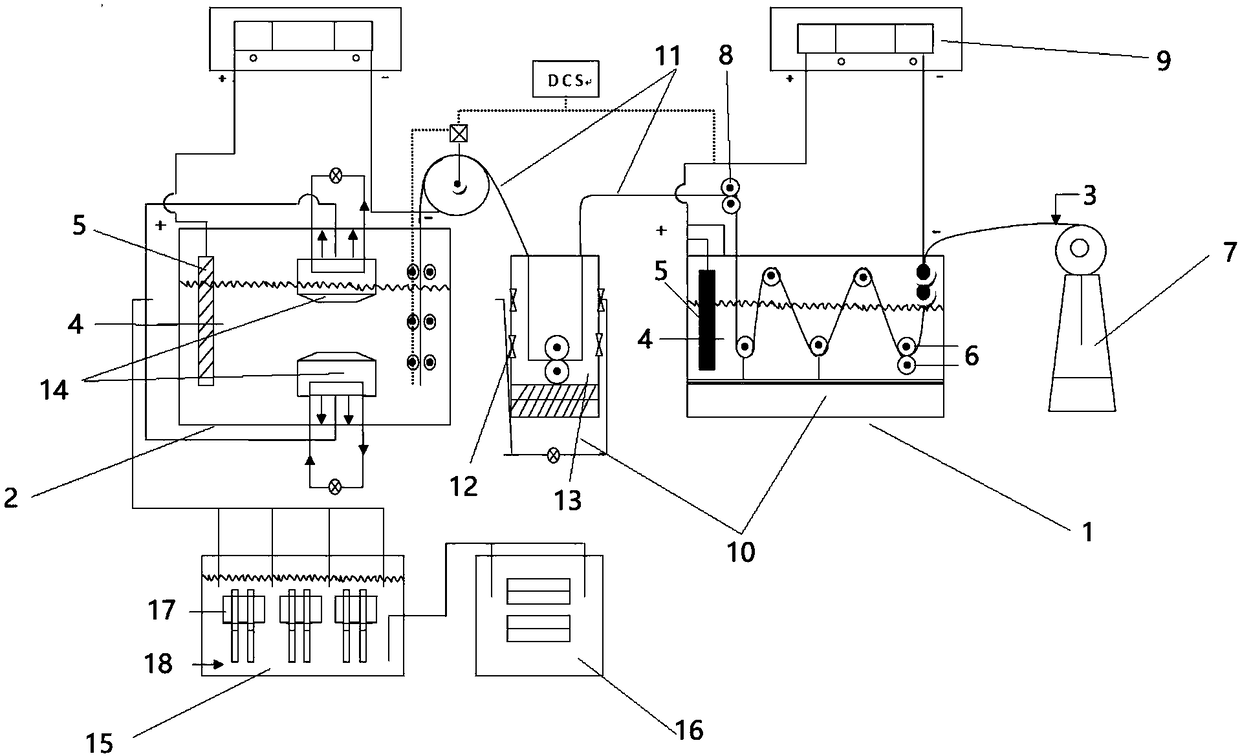

[0032] Such as figure 1 As shown, a kind of device of this embodiment adopts electrochemical process to mass-produce graphene, and the device related to electrochemical process is electrochemical intercalation tank 1 and electrochemical stripping tank 2, and also includes a stripping tank between the two tanks. A pretreatment tank 13, an ultrasonic stripping tank 15 connected to the electrochemical stripping tank, and a centrifugal drying device 16.

[0033] In the electrochemical intercalation tank 1 is the copper sulfate electrolyte 4, before the electrochemical intercalation tank 1 there is a support 7, on which the flexible graphite roll wound by the flexible graphite paper 3 is placed, through the conveying device and the supporting roller 6, etc. Continuously transport the flexible graphite paper 3 into the electrolyte solution 4 as the negative electrode, and the positive electrode 5 is a stainless steel rod. The positive and negative poles are respectively connected t...

Embodiment 2

[0041] The stripping pretreatment tank 13 in embodiment 1, the ultrasonic stripping tank 15 and the centrifugal drying device 16 connected to the electrochemical stripping tank are not included in this embodiment, and only the simplification of the electrochemical intercalation tank 1 and the electrochemical stripping tank 2 is included. When the device has low requirements on the number of graphene layers, the production process can be simplified and the cost can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com