Multi-sprayer FDM-3D printer with belt-idler drive

A FDM-3D, multi-nozzle technology, applied in the mechanical field, can solve the problems of inaccurate printing, large inertia, and high quality of the printing head, and achieve the effect of reliable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

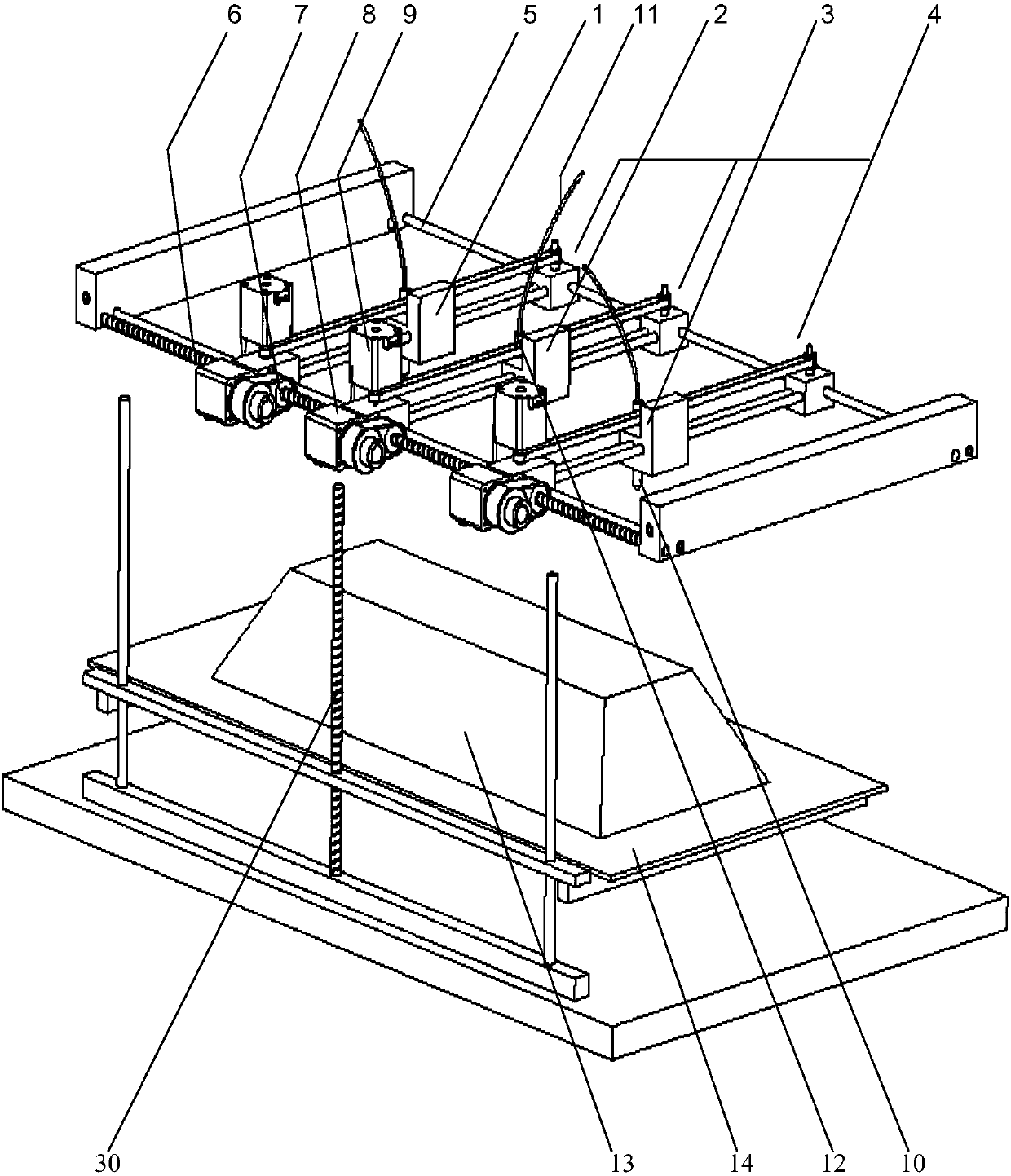

[0013] [Multi-nozzle FDM-3D printer with belt-idler drive] Features:

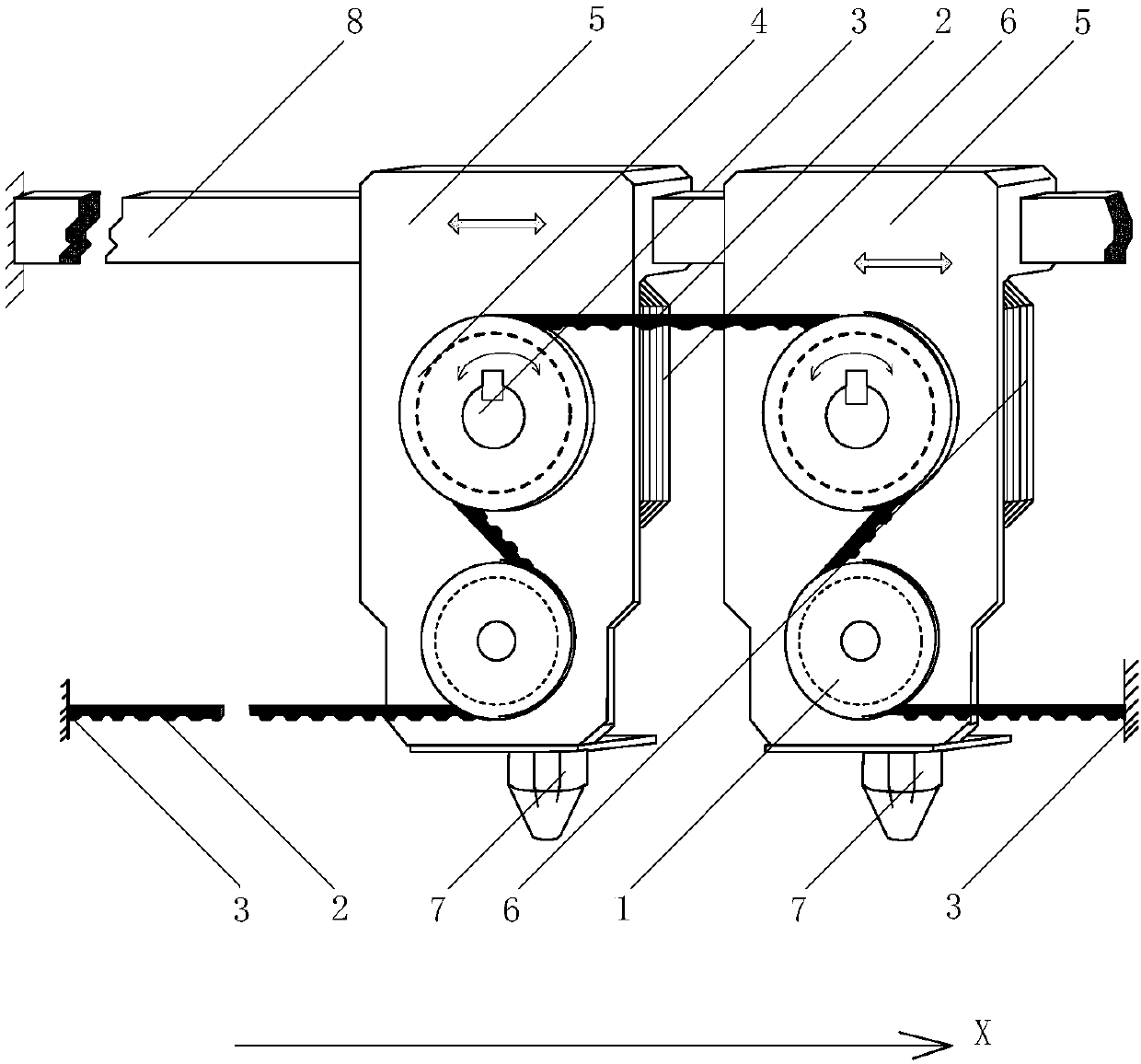

[0014] The printer includes: a plurality of (2-100) extruder assemblies, a mechanical device or a gear / rack that carries the extruder assembly for 2-dimensional horizontal X, Y-axis movement with a belt-idler drive structure or Screw / sim transmission mechanism (the mechanical device includes: X-direction and Y-direction track mechanism), printing platform and lifting mechanism, electric control system, control panel and structural shell. The arrangement of the multi-extruder assembly system is divided into : Single X arrangement splicing method and multi-row Y arrangement splicing method.

[0015] Single X arrangement splicing method:

[0016] Multiple extruder assemblies carry their own extrusion nozzles, driven by their respective X drive motors, reciprocating along the guide rails; It reciprocates along the X direction under traction; the role of the belt idler is to increase the contact number of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com