High-temperature-resistant photovoltaic cable and construction method

A technology for photovoltaic cables and high temperature resistance, which is applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., which can solve the problems of short service life, poor high temperature resistance of photovoltaic cables, aging cracking and failure, etc. The effect of ultraviolet radiation and the effect of preventing excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

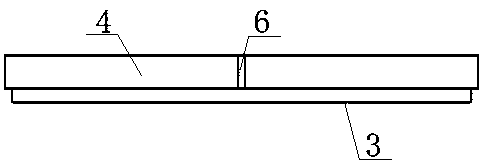

[0021] A high-temperature-resistant photovoltaic cable, which consists of: a conductor 1 and an insulating outer layer 3 arranged outside the conductor, and a temperature-insulating filler 2 is filled between the conductor and the insulating outer layer, and the temperature-insulating filler Made of nano-ceramic hollow microspheres, it has super-strong temperature insulation performance. The upper part of the insulating outer layer is respectively connected to a group of semicircular sunshade baffles 4 through springs 7, and the two adjacent sunshade baffles The space is connected by plastic cloth 6, and the sunshade baffle is provided with a layer of temperature-insulating inner pad 5, which is made of plastic foam material and has good temperature-insulating performance. Bonded to the sun visor.

Embodiment 2

[0023] According to the high-temperature-resistant photovoltaic cable described in Embodiment 1, the inner diameter of the sunshade plate is greater than three times the outer diameter of the insulating outer layer.

Embodiment 3

[0025] According to the high temperature resistant photovoltaic cable described in embodiment 1 or 2, the width of the plastic cloth is less than 2 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com