Construction equipment and method for waste silt shallow layer in-situ curing

An in-situ solidification and construction equipment technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of poor solidification uniformity, heavy equipment, low work efficiency, etc., to ensure strength and uniformity, and reduce silt Moisture content, the effect of improving soil strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

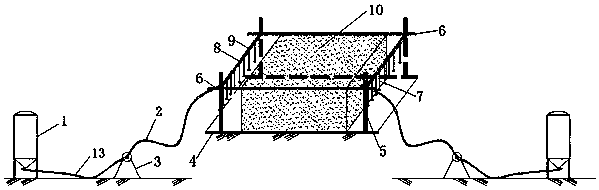

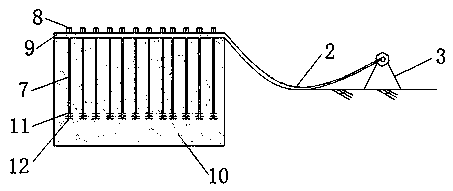

[0048] The water content of the waste sludge to be treated is 58%, and the bulk density is 1.79t / m 3 In the project, it is required that the strength of the solidified silt reaches 250kPa after 90 days of age, so as to reduce the uneven settlement of the foundation. The construction method of in-situ solidification of the shallow layer of waste silt includes the following steps:

[0049] S0: Curing agent slurry can be selected from existing ones on the market according to needs; carry out indoor curing test on the sludge 10 to be solidified, and determine the relationship between the unconfined compressive strength of the sludge 10 to be solidified and the water-cement ratio;

[0050] S1, leveling the rectangular area around 50cm away from the waste silt, the leveling width is 80cm, select the long side direction of the rectangular area, the length is about 326m, and lay the bottom temporary light walking track 4 and the upper temporary light walking track 6 in parallel;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com