A high-molybdenum-nickel-based alloy thin plate with a width ≥ 1000 mm, its manufacturing method and application

A manufacturing method and alloy-based technology, applied in the field of composition and manufacturing of nickel-based corrosion-resistant alloy wide sheets, can solve problems that cannot fully meet the requirements for the use and manufacture of nuclear main pump shielding sleeves, and achieve the promotion of independent construction and improvement Effects of hot workability, improvement of strength and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

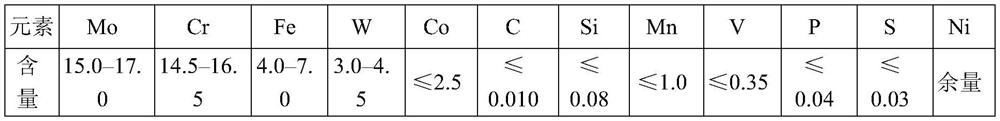

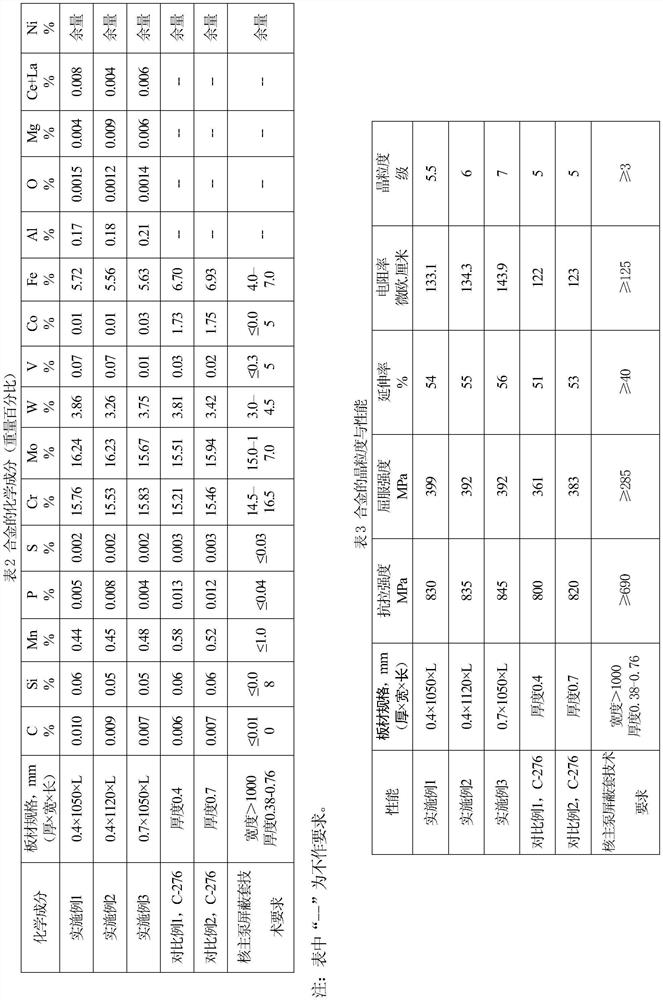

Method used

Image

Examples

Embodiment 1

[0073] According to the composition described in this embodiment in Table 2, 7 tons of high-molybdenum-nickel-based alloy flat electrodes were smelted by 12 tons of vacuum induction. An electroslag flat ingot with a thickness of 320 mm, a width of 1190 mm and a length of 1650 mm was obtained by protecting the electroslag remelting furnace with argon gas.

[0074] The electroslag slab is made into a slab after billeting. The slab is rolled in a heating furnace at 1100°C for 3 hours. The rolling temperature is 1060°C, the final rolling temperature is 960°C, and the rolled width is 1070mm. of hot-rolled steel coils.

[0075] The hot-rolled steel coil is cold-rolled in 5 rolling passes, and finally rolled into a cold-rolled steel coil with a width of 1050 mm and a thickness meeting the requirements. Among them, intermediate annealing treatment is required between each rolling pass, and the intermediate annealing treatment temperature is 1120 ° C, and heating is performed for 1.5 ...

Embodiment 2

[0078] According to the composition described in this embodiment in Table 2, 7 tons of high-molybdenum-nickel-based alloy flat electrodes were smelted by 12 tons of vacuum induction. An electroslag flat ingot with a thickness of 350 mm, a width of 1250 mm and a length of 1800 mm was obtained by protecting the electroslag remelting furnace with argon gas.

[0079] Electroslag slabs are made into slabs after blanking. The slabs are rolled out of the furnace after being kept at 1180°C for 4.5 hours in a heating furnace. 1220mm hot rolled steel coil.

[0080] The hot-rolled steel coil is cold-rolled through 6 rolling passes, and finally rolled into a cold-rolled steel coil with a width of 1120 mm and a thickness meeting the requirements. Among them, intermediate annealing treatment is required between each rolling pass. The intermediate annealing treatment temperature is 1180 ° C, and the heating is 2.2 minutes per millimeter. The rolling deformation rate of the final rolled pro...

Embodiment 3

[0083] According to the composition described in this embodiment in Table 2, 7 tons of high-molybdenum-nickel-based alloy flat electrodes were smelted by 12 tons of vacuum induction. An electroslag flat ingot with a thickness of 380 mm, a width of 1330 mm and a length of 1950 mm was obtained by protecting the electroslag remelting furnace with argon gas.

[0084] The electroslag slab is made into a slab after billeting, and the slab is rolled out of the furnace after being kept at 1220°C for 5.5 hours in a heating furnace. The rolling temperature is: 1130°C, the final rolling temperature is 990°C, and the rolled width is 1150mm. width of hot-rolled steel coils.

[0085] The hot-rolled steel coil is cold-rolled through 4 rolling passes, and finally rolled into a cold-rolled steel coil with a width of 1050 mm and a thickness meeting the requirements. Among them, intermediate annealing treatment is required between each rolling pass. The intermediate annealing treatment temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com