Method and application for recovering metal from bag dust of reverberating furnace

A bag ash, reverberatory furnace technology, applied in the direction of improving process efficiency, can solve problems such as waste of resources, and achieve the effect of less environmental pollution and good benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

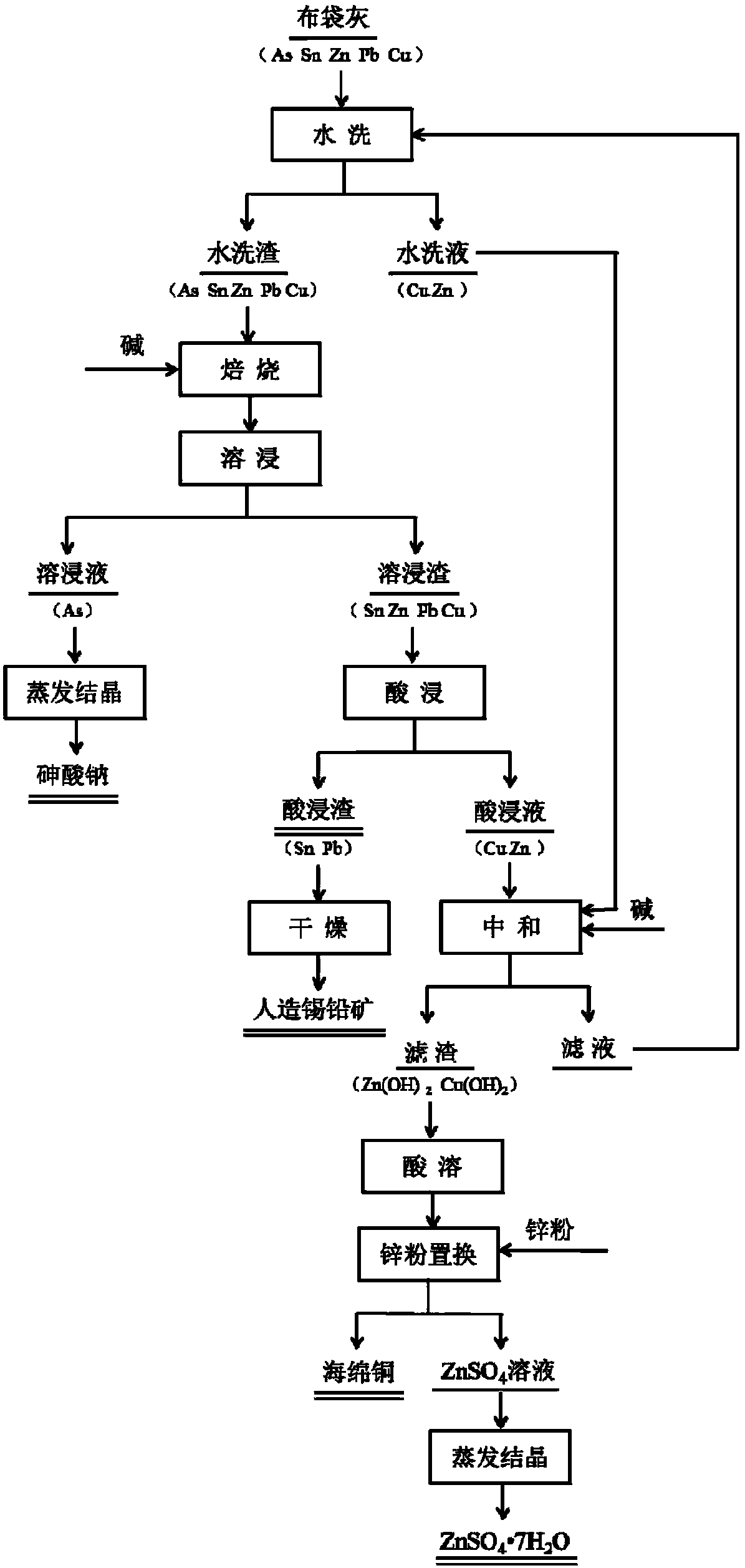

Method used

Image

Examples

Embodiment 1

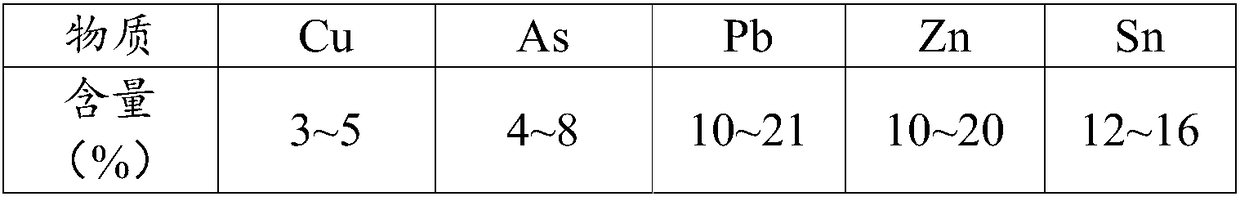

[0036] This embodiment provides a method for recovering metal from reverberatory furnace bag ash, mainly comprising:

[0037] Mix the reverberatory furnace bag ash and water at a solid-to-liquid ratio of 1g:3mL, stir for 60min at room temperature, and filter to obtain the washing liquid and washing residue. The mass fractions of components in the washed slag are: As 5.31%, Sn 12.38%, Pb 14.89%, Zn 20.31%, Cu 3.76%, and the washing solution contains Zn 3.37g / L and Cu 1.36g / L.

[0038] The water-washed residue and sodium carbonate were mixed at a mass ratio of 1:1.2, and roasted at a temperature of 550° C. for 3 hours to obtain a roasted product.

[0039] The calcined product was pulverized and ground to 70 mesh. The roasted product and water were mixed at a solid-to-liquid ratio of 1g:3mL, reacted at a temperature of 85°C for 2 hours, and the stirring intensity was 200rpm, and filtered to separate the solid and liquid to obtain the leaching residue and leaching liquid. Among ...

Embodiment 2

[0045] This embodiment provides a method for recovering metal from reverberatory furnace bag ash, mainly comprising:

[0046] Mix the reverberatory furnace bag ash and water at a solid-to-liquid ratio of 1g:4mL, stir for 30 minutes at room temperature, and filter to obtain the washing liquid and washing residue. The mass fractions of components in the washed slag are: As 5.31%, Sn 12.38%, Pb 14.89%, Zn 20.31%, Cu 3.76%, and the washing solution contains Zn 3.37g / L and Cu 1.36g / L.

[0047] Mix the water-washed slag and sodium carbonate at a mass ratio of 1:1, and roast at a temperature of 650°C for 2 hours to obtain a roasted product.

[0048] The roasted product was pulverized and ground to 90 mesh. The roasted product and water were mixed at a solid-to-liquid ratio of 1g:4mL, reacted at a temperature of 80°C for 3 hours, and the stirring intensity was 250rpm, and filtered to separate the solid and liquid to obtain the leaching residue and leaching liquid. Among them, the le...

Embodiment 3

[0054] This embodiment provides a method for recovering metal from reverberatory furnace bag ash, mainly comprising:

[0055] Mix the reverberatory furnace bag ash and water at a solid-to-liquid ratio of 1g:3mL, stir at room temperature for 60min, and filter to obtain the washing liquid and washing residue. The mass fraction of the ingredients in the washed slag is: As5.21%, Sn 12.13%, Pb 14.60%, Zn 20.34%, Cu 4.08%, the washing liquid contains Zn 3.02g / L, Cu 0.54g / L, As, Sn, Pb Does not leach. The recovery rate of Cu was 96.03%, and the recovery rate of Zn was 95.57%.

[0056] The water-washed residue and sodium carbonate were mixed at a mass ratio of 1:1.4, and roasted at a temperature of 600°C for 3 hours to obtain a roasted product.

[0057] The roasted product was pulverized and ground to 80 mesh. The roasted product and water were mixed at a solid-to-liquid ratio of 1g:3mL, reacted at a temperature of 75°C for 4 hours, and the stirring intensity was 300rpm, and filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com