Method for preparing breads through fermentation of natural compound yeast

A natural yeast and bread technology, applied in the food field, can solve the problems of limited family and handicraft workshops, difficulty in controlling the fermentation process, unstable product flavor, etc., and achieve similar fermentation performance, shortened cultivation period, and large specific volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 Natural fermentation natural yeast liquid and the preparation of natural yeast stock

[0031] 1. Cultivation of fruit natural yeast liquid: wash the grapes with water, drain the water, take 200g into a sterilized sealed tank, add 500g of sterile water and 40g of sugar, stir evenly, seal and place at room temperature, ferment for 8 days, every day Open the bottle cap once, stir with sterilized chopsticks, wait until a large number of bubbles appear and emit wine aroma, and filter to obtain grape natural yeast liquid.

[0032] 2. Cultivation of fruit natural yeast original species: the first day: take 300g grape natural yeast liquid and mix with 300g flour, and place it in an environment with a temperature of 18-25°C and a humidity of 40%-85% for 24 hours; the second day: take Leave 300g of the grape natural yeast mud from the previous day, mix it with 300g of grape natural yeast liquid and 300g of flour, and place it at a temperature of 18-25°C and a humidit...

Embodiment 2

[0033] The preparation of embodiment 2 compound natural yeast

[0034] 1. Inoculate Saccharomyces cerevisiae, Lactobacillus brevis, Lactobacillus rhodus and Lactobacillus plantarum in the corresponding medium (yeast: YPD, lactic acid bacteria: MRS) at 26-30°C (Saccharomyces cerevisiae, Lactobacillus brevis bacillus) and 35-39°C (Lactobacillus rheumatus and Lactobacillus plantarum) for 8-14 hours, collect the bacteria in the growth index phase, centrifuge at 3500-5000rpm for 10-20 minutes, remove the supernatant, and use 5-50 Double the volume of sterile water to wash the cells twice, and centrifuge to remove the supernatant.

[0035] 2. Resuspend the bacteria with 10 to 50 times the volume of sterilized water, and use the turbidimetric method to measure the concentration of the bacteria solution. The concentration of each bacteria solution reaches 10 8 ~10 10 individual / mL.

[0036] 3. The resuspended bacterial solution is compounded according to different proportions (volu...

Embodiment 3

[0040] The preparation of embodiment 3 bread

[0041] 1. Take 20-25 parts of high-gluten flour, 9-14 parts of the compound natural yeast prepared in Example 2, 1.2-1.5 parts of milk, 0.9-1.2 parts of organic sugar, 0.3-0.5 parts of salt, and 0.8-1 part of butter , 8-13 parts of water at 20-25°C are mixed and stirred to form a dough at 20-25°C;

[0042] 2. Ferment at room temperature of 18-25°C for 1.5-4 hours;

[0043] 3. Shaping: Divide the bread dough into 50-80g / parts, and shaping;

[0044] 4. Proofing: Proofing the shaped dough at a temperature of 28-38°C and a relative humidity of 70-85% for 1-3 hours;

[0045] 5 Baking: Put the proofed dough into the oven and bake to get the bread. The baking temperature is 180-220°C for upper heat, 170-190°C for lower heat, and the baking time is 25-30 minutes.

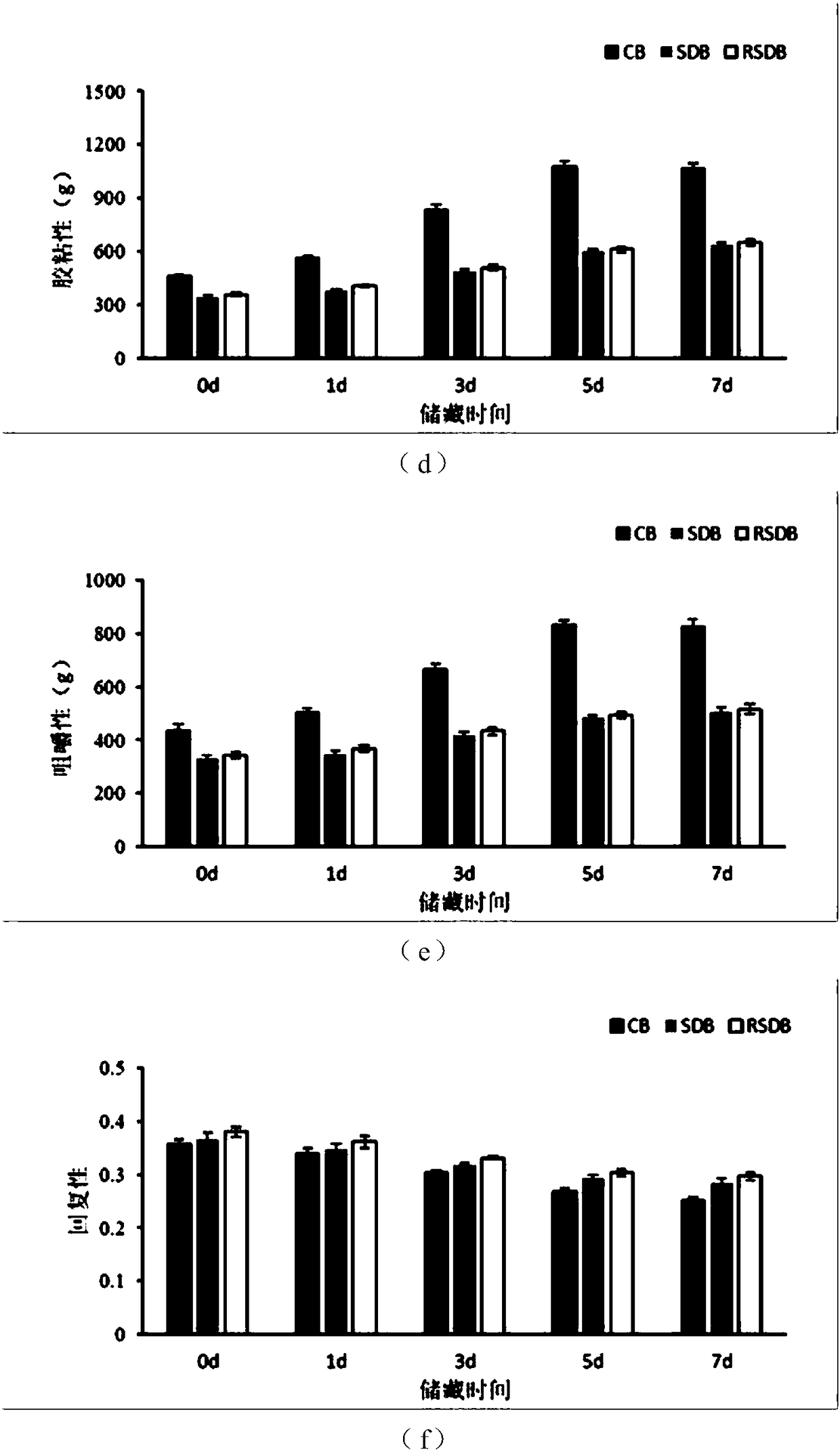

[0046] The impact of different compounding ratios on bread quality is compared, as shown in Table 2.

[0047] Table 2 Effects of different compounding ratios on bread quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com