Building waste clay brick burn-free light-weight aggregate and preparation method of same

A technology of construction waste and clay bricks, which is applied in the field of building materials, can solve the problems of unsuitable large-scale use, slow activity, high crushing index, etc., and achieve the effects of saving precious land, simple process, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

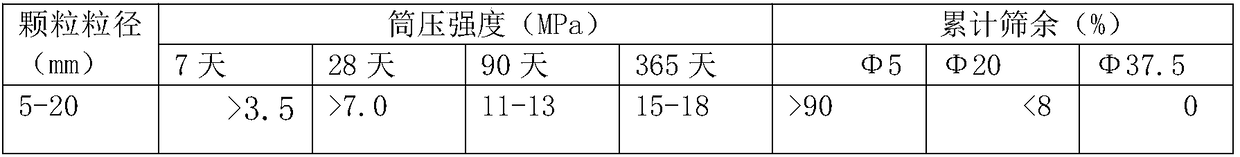

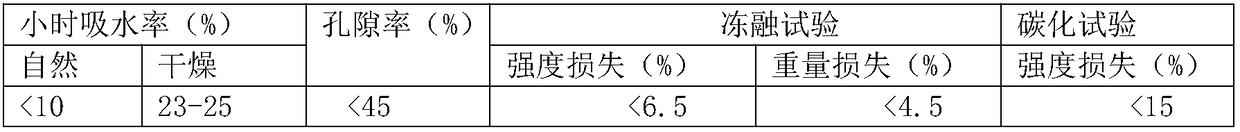

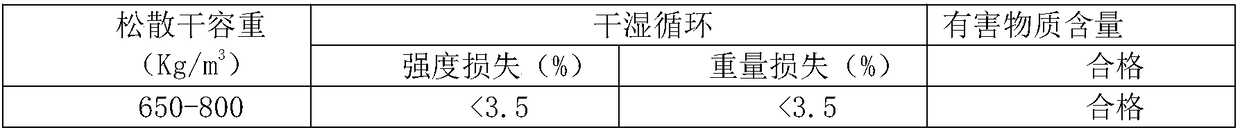

[0018] A construction waste clay brick non-burning lightweight aggregate comprises 85 parts of construction waste clay bricks, 11 parts of high alumina cement clinker, 3 parts of limestone and 1 part of anhydrite. The high-alumina cement clinker is first crushed in a 400x600mm crusher, and then fed into a Φ1.5x6.5m ball mill for mixing and grinding. The fineness of the mixture is 0.075mm and the residual amount of the square hole sieve is 4.5%. Use Φ2.5m ball discs to form balls, the inclination of the ball discs is 60 degrees, the amount of water added is 25.5%, the particle size is 5-20mm, and the natural temperature is 20-25 degrees, and the humidity is 70-80%. Cured into light aggregates. The cylinder compressive strength is 4.0MPa in 3 days, 7.5-8.5MPa in 28 days, and the bulk density is 600-750kg / m 3 The hourly water absorption rate is less than 30%, the natural state is less than 12%, the softening coefficient is greater than 0.75 (natural state 0.85), the antifreeze t...

Embodiment 2

[0020] A construction waste clay brick non-burning lightweight aggregate, using 80 parts of construction waste clay bricks, 14 parts of high alumina cement clinker, 4 parts of limestone and 3 parts of anhydrite, the fineness of the mixture is 0.075mm square hole sieve The balance is 3.0%. Add 24.5% water when forming into balls, and cure them into lightweight aggregates at a natural temperature of 30 degrees and a humidity of 95%. The cylinder compressive strength is 4.9MPa in 7 days and 8.2MPa in 28 days, and other properties are the same as in Example 1.

Embodiment 3

[0022] A construction waste clay brick non-fired lightweight aggregate, using 75% of construction waste clay bricks, 17% of high alumina cement clinker, 5% of limestone, 3% of anhydrite, and the fineness of the mixture is 0.075mm square hole sieve The balance is 4.0%. When forming balls, add 23.5% water, and maintain green aggregates at a natural temperature of 26 degrees and a humidity of 90%. The cylinder compressive strength is 4.7MPa in 7 days, 6.3MPa in 14 days, and 8.4MPa in 28 days. Other performances are the same as in Example 1.

[0023] In the present invention, high-alumina cement clinker is used as an activator, which has a strong stimulating effect on the activity of construction waste clay bricks. The lightweight aggregate prepared with high-alumina cement clinker not only has high early strength, but when an appropriate amount of limestone and After anhydrite, the late strength of lightweight aggregate is significantly improved, and a large amount of constructi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com