Perovskite LED containing organic-inorganic hybrid perovskite monocrystal light emitting layer, and preparation method

A perovskite and light-emitting layer technology, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as device leakage, poor device stability, and affect the stability of perovskite LEDs, and achieve layer structure Controlled, thickness-optimized results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

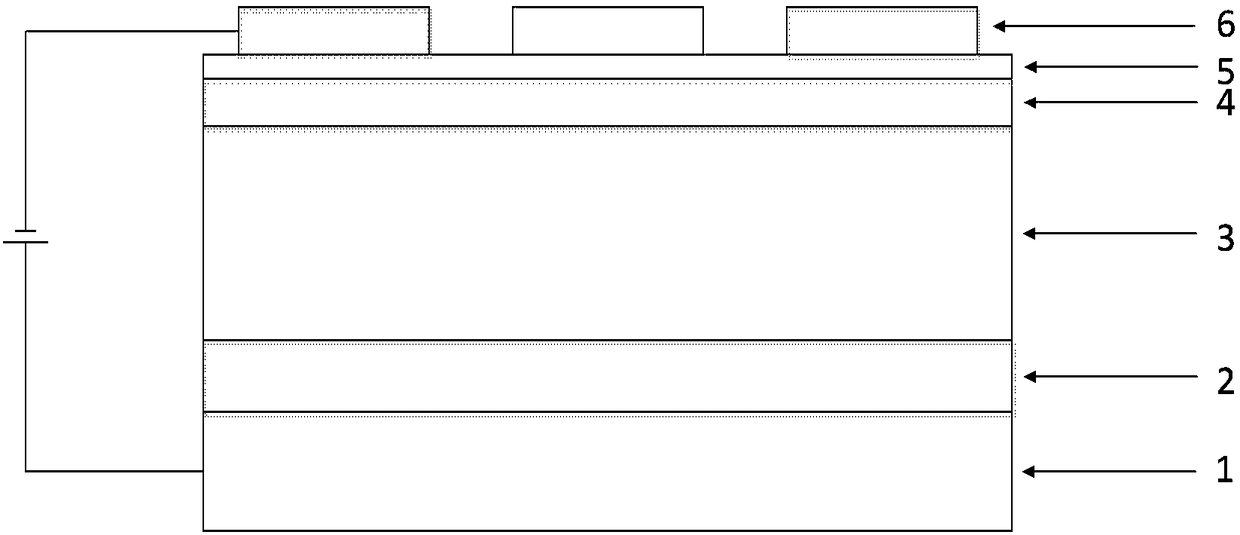

[0050] figure 1 It is a schematic structural diagram of the perovskite LED according to the first embodiment of the present disclosure. Please refer to figure 1 , the present disclosure is a perovskite LED containing an organic-inorganic hybrid perovskite single crystal light-emitting layer, comprising:

[0051] CH 3 NH 3 PbBr 3 Perovskite single crystal light-emitting layer 3;

[0052] The p-type hole transport layer 2 is formed on CH along the first direction 3 NH 3 PbBr 3 On the perovskite single crystal light-emitting layer;

[0053] A transparent conductive anode 1 formed on the p-type hole transport layer;

[0054] The n-type electron transport layer 4 is formed on CH along a second direction opposite to the first direction 3 NH 3 PbBr 3 On the perovskite single crystal light-emitting layer;

[0055] An electron injection layer 5 formed on the n-type electron transport layer; and

[0056] The metal electrode 6 is formed on the electron injection layer.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com