Large-area super-resolution photoetching device

A super-resolution, large-area technology, applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of mask substrate limitation and influence, and achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to make the objectives, technical solutions, and equipment advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

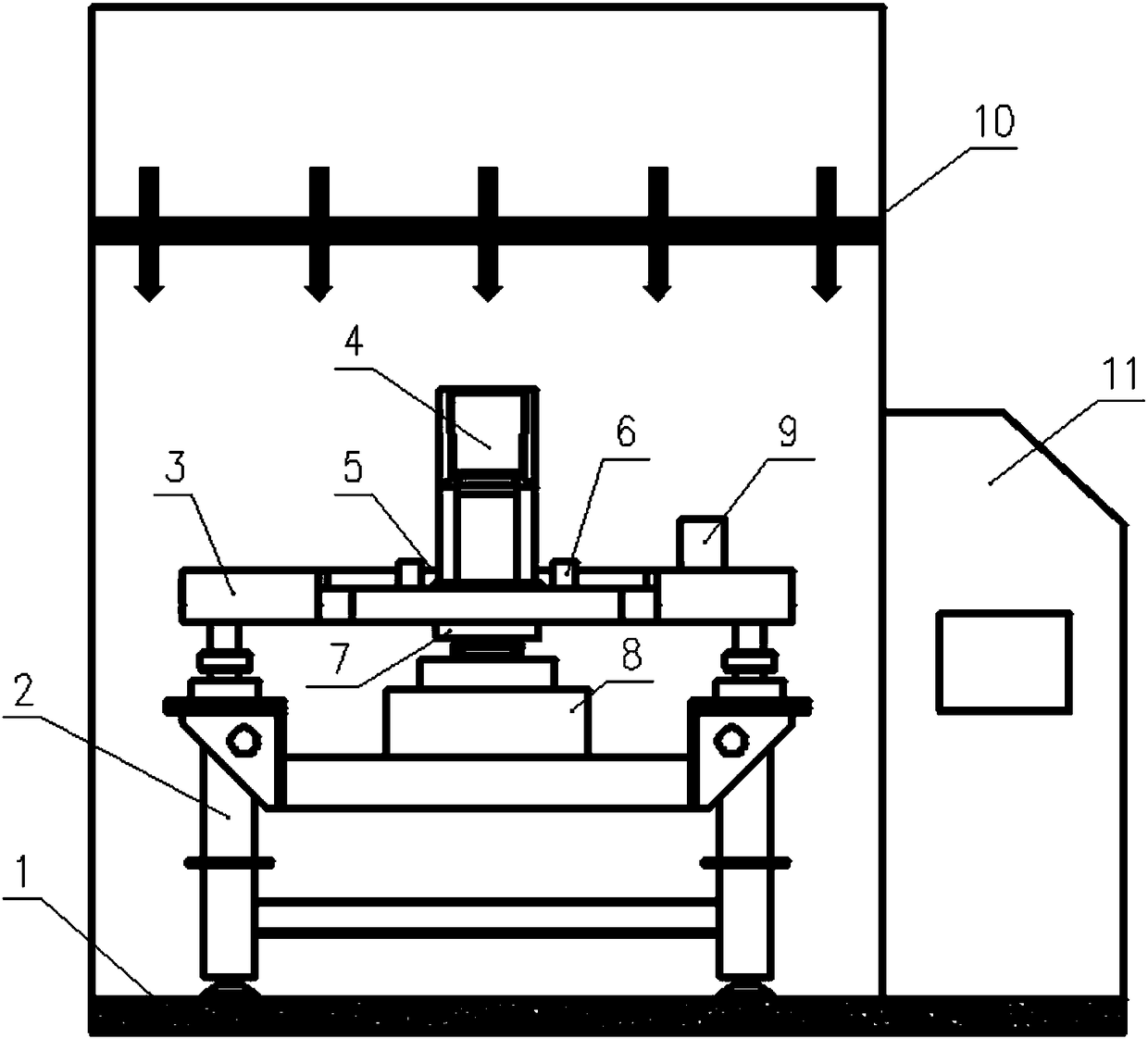

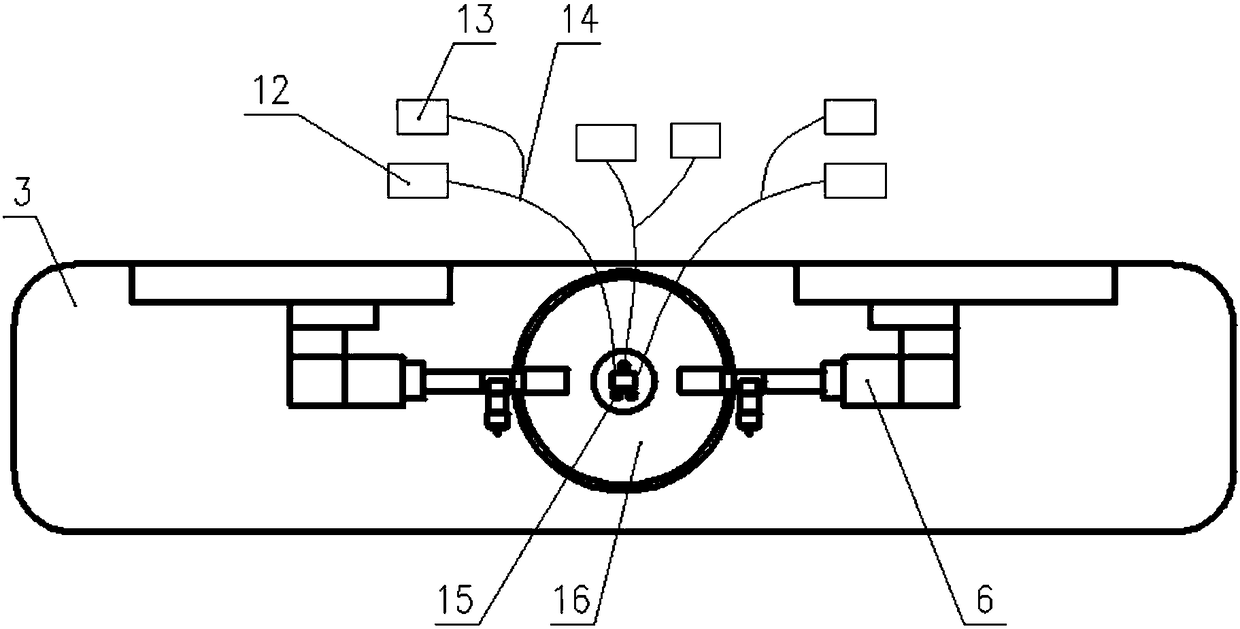

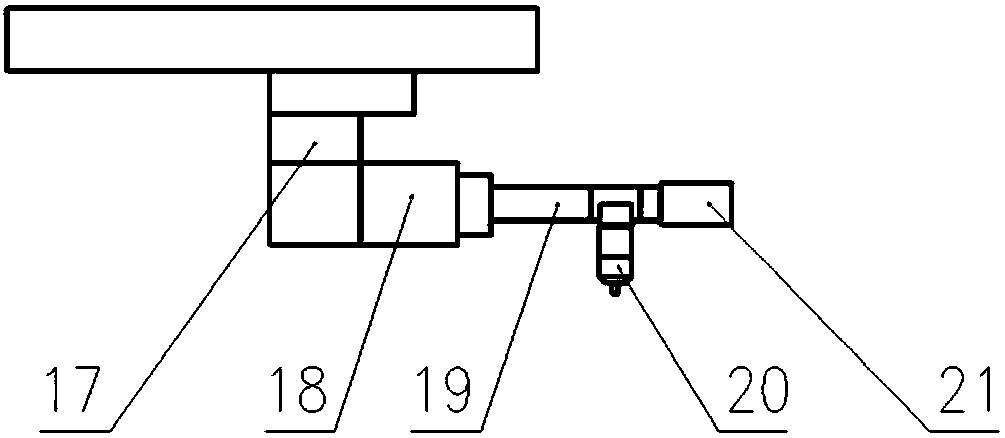

[0074] Reference figure 1 , A large-area super-resolution lithography device, the device is mainly composed of vibration isolation foundation 1, active vibration isolation platform 2, main substrate 3, ultraviolet exposure light source 4, gap detection system 5, alignment module 6, super-resolution lithography lens It is composed of module 7, workpiece table module 8, six-axis laser interferometry system 9, ultra-precision environmental control system 10 and control system 11. Among them, the vibration isolation foundation 1 and the active vibration isolation platform 2 can achieve vibration isolation effects above VC-E; the ultra-precision environmental control system 10 provides the entire super-resolution lithography equipment with a temperature of 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com