Diesel DPF cleaning regenerating agent and application thereof

A technology of DPF and regeneration agent, which is applied in the direction of detergent compounding agent, detergent composition, organic detergent composition, etc., can solve the problems of thermal damage of filter body, economic loss, rise of back pressure of exhaust pipe, etc., and achieve optimal cleaning Effect, reduction of maintenance or replacement cost, effect of reduction in fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Raw material composition: dimethyl carbonate 17.0%, sodium lignosulfonate 8%, sodium salicylate 12%, diethylene glycol methyl ether 4.5%, TEGO755 7.5%, fatty alcohol polyoxyethylene ether 1.0%, fatty acid methyl ester Ethoxylate 2.8%, benzotriazole 0.5% and deionized water 46.7%.

[0018] Preparation method: add dimethyl carbonate and sodium salicylate to deionized water, then add diethylene glycol methyl ether, and stir to obtain a uniform mixed solution; add TEGO755 and sodium lignosulfonate to the prepared mixed solution, After stirring evenly, add fatty alcohol polyoxyethylene ether, fatty acid methyl ester ethoxylate, and benzotriazole, stir slowly to obtain a uniform liquid, and filter to obtain the DPF cleaning and regeneration agent.

[0019] The raw materials used in the present invention can be purchased from the market.

[0020] The diesel engine DPF cleaning and regenerating agent of the present invention is applied to the regeneration process of the DPF sy...

Embodiment 2

[0025] Composition of raw materials: 14.0% isopropanol, 10.0% sodium lignosulfonate, 13.0% sodium salicylate, 3.5% dipropylene glycol dimethyl ether, 8.0% Tween 80, 3.5% polyoxyethylene alkylamine, lauramide propane 3.5% amine oxide, 0.7% triethanolamine borate and 43.8% deionized water.

[0026] Preparation method: Add isopropanol and sodium salicylate to deionized water, then add dipropylene glycol dimethyl ether, and stir to obtain a uniform mixture; add Tween 80 and sodium lignosulfonate to the prepared mixture, After stirring evenly, add polyoxyethylene alkylamine, lauryl amidopropyl amine oxide, and triethanolamine borate, stir slowly to obtain a uniform liquid, and filter to obtain a DPF cleaning and regeneration agent.

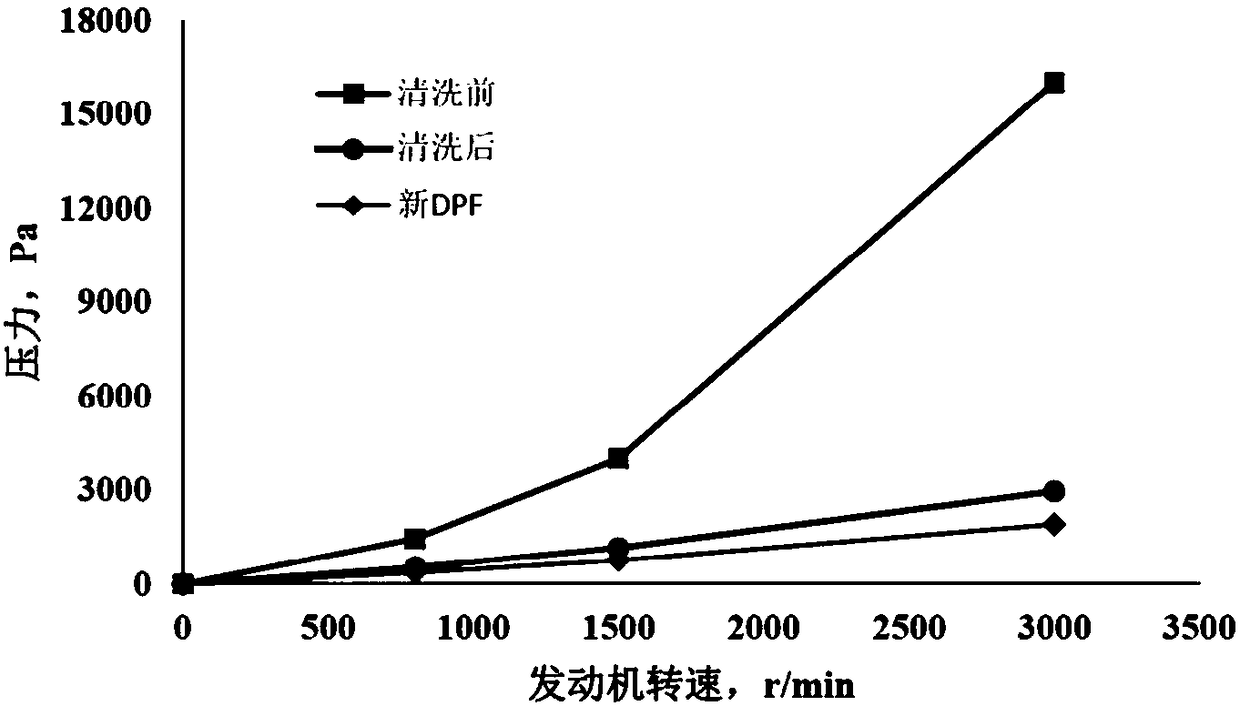

[0027] Test: choose a blocked DPF exhaust processor as the experimental object, the specific information is: manufacturer: Wuxi Diesel Engine Factory, engine model: 4DW93-84E5-JHK1C, displacement: 2.54L, rated speed: 3000r / min, fuel type: diesel , run...

Embodiment 3

[0032]Raw material composition: ethanol 6.0%, dimethyl carbonate 13.0%, sodium lignosulfonate 4.0%, sodium salicylate 9.0%, diethylene glycol butyl ether 3.0%, dipropylene glycol dimethyl ether 1.5%, TEGO755 9.0%, 2.0% fatty acid diethanolamide, 2.8% fatty acid methyl ester ethoxylate, 2.0% alkyl glycoside, 0.8% benzotriazole and 46.9% deionized water.

[0033] Preparation method: Add ethanol, dimethyl carbonate and sodium salicylate into deionized water, then add diethylene glycol butyl ether and dipropylene glycol dimethyl ether, and stir to obtain a uniform mixture; add TEGO755 and sodium lignosulfonate, stir evenly, then add fatty acid diethanolamide, fatty acid methyl ester ethoxylate, alkyl glucoside, benzotriazole, stir slowly to obtain a uniform liquid, filter, and obtain DPF cleaning and regeneration agent .

[0034] The cleaning and regenerating agent was tested for performance, and the obtained results are shown in Table 3.

[0035] Table 3 The quality of clogged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com