Functional nano-titanium dioxide grafted with antioxidant molecules on surface and preparation method of functional nano-titanium dioxide

A technology of nano-titanium dioxide and surface grafting, which is applied in the field of functionalized nano-titanium dioxide, which can solve the problems of easy loss, easy migration, and poor extraction resistance, and achieve the effects of not easy to seep out, improve dispersion, and overcome poor extraction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

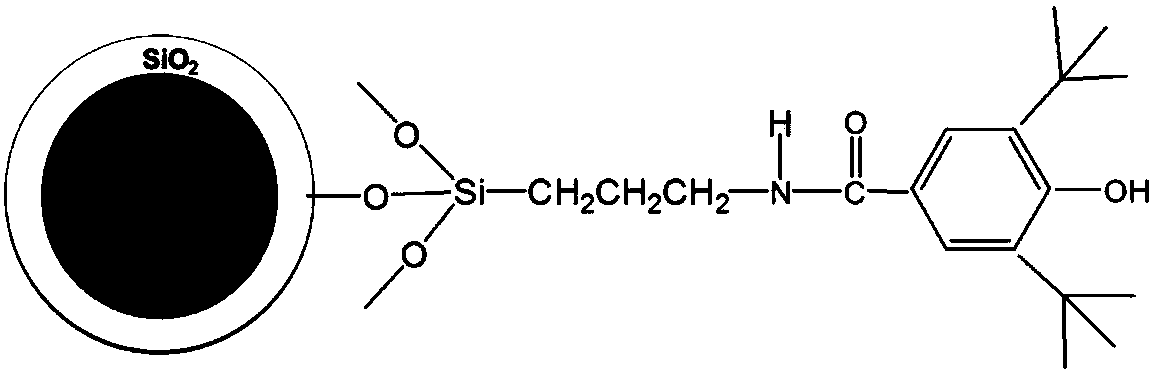

[0053] Another specific embodiment of the present invention discloses a method for preparing functionalized nano-titanium dioxide grafted with antioxidant molecules on the surface. First, a layer of silicon dioxide is coated on the surface of nano-titanium dioxide by hydrolysis of orthosilicate , the nano-layer silica coated on the surface of nano-titanium dioxide can greatly inhibit the catalytic effect of nano-titanium dioxide on the polymer matrix; On the titanium dioxide particles; after the aminosilane coupling agent is hydrolyzed, it first condenses with the silicon dioxide coated on the surface of the nano-titanium dioxide to obtain nano-titanium dioxide core-shell particles coated with nano-silica modified by the aminosilane coupling agent, and then Grafting the acid chlorinated antioxidant molecules to another functional amino group of the coupling agent to obtain functionalized nano-titanium dioxide with antioxidant molecules grafted on the surface; the specific steps...

Embodiment 1

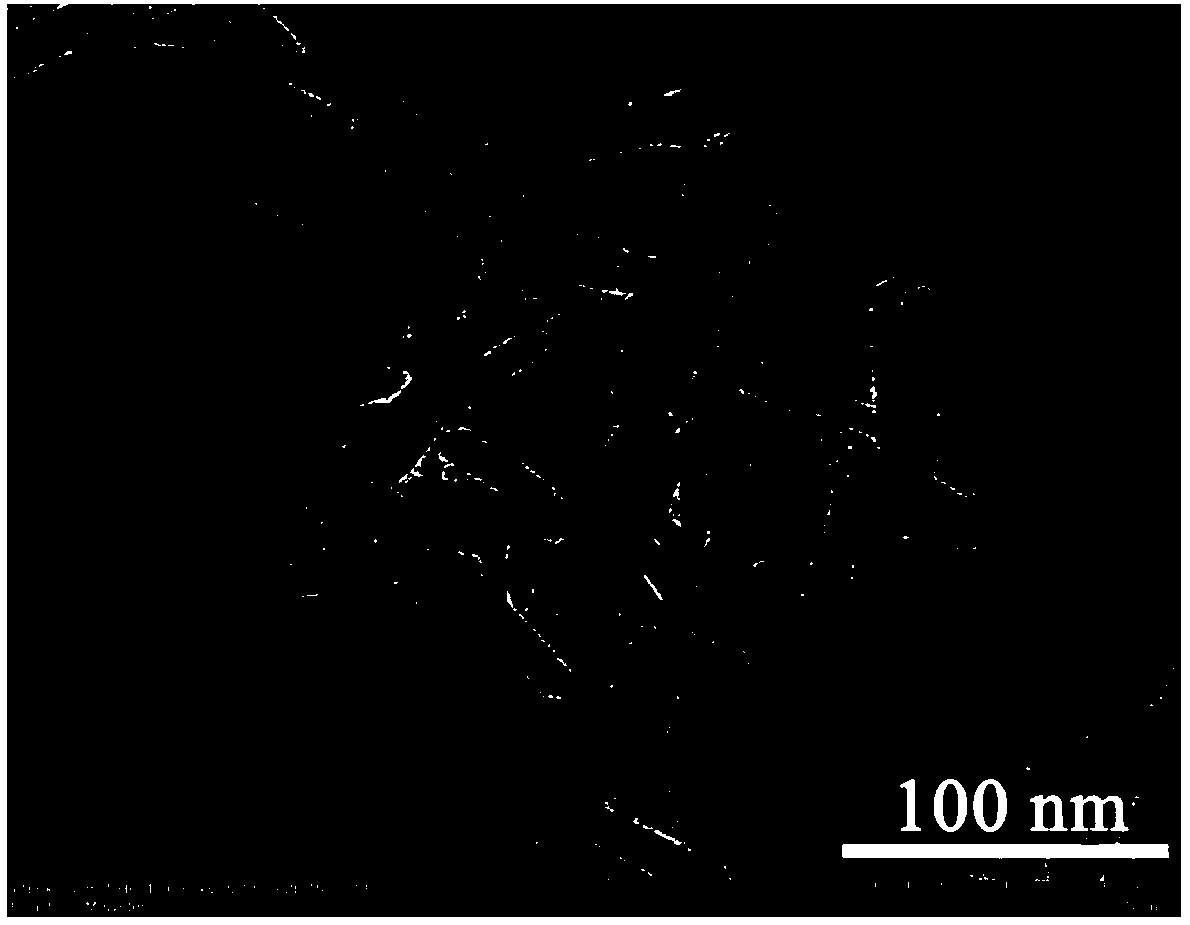

[0062] The titanium dioxide nanoparticles in this example are titanium dioxide nanorods prepared by a low-temperature hydrothermal method, with a length of about 70 nm and a diameter of about 8 nm. The surface contains a large number of hydroxyl groups and has strong hydrophilicity.

[0063] Preparation of nano-titanium dioxide coated with silicon dioxide: Coating titanium dioxide by hydrolysis of ethyl orthosilicate, weighing 7.5g of nano-titanium dioxide and 300ml of ethanol into a 1L three-necked flask, adding 15g of it dropwise under stirring at 300r / min Ethyl orthosilicate, then use ammonia water to adjust PH = 10, react at 30°C for 24h; wash the product with absolute ethanol until neutral, filter to obtain a silica-coated nano-titanium dioxide filter cake, and then place the filter cake at 80°C Dry in a blast oven for 24 hours, and grind to obtain nano-titanium dioxide powder coated with silicon dioxide.

[0064] Preparation of γ-aminopropyltrimethoxysilane-grafted silic...

Embodiment 2

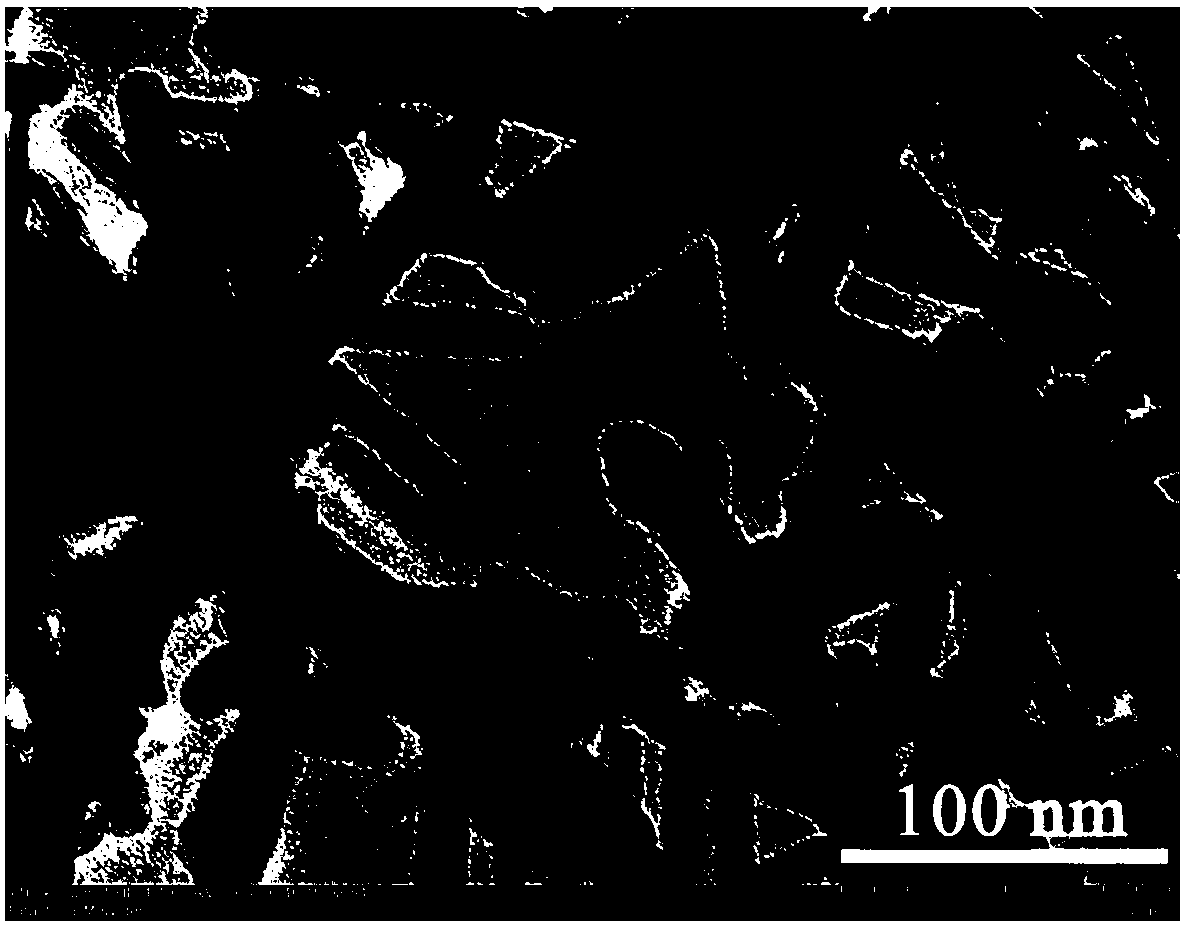

[0069] The nano-titanium dioxide particles in this embodiment are spherical nano-titanium dioxide particles prepared by a gas phase method, and the primary particle diameter is about 20 nanometers.

[0070] Preparation of nano-titanium dioxide coated with silicon dioxide: Coating titanium dioxide by hydrolysis of ethyl orthosilicate, weighing 7.5g of nano-titanium dioxide and 300ml of ethanol into a 1L three-necked flask, adding 15g of it dropwise under stirring at 300r / min Ethyl orthosilicate, then adjust the pH to 10 with ammonia water, and react at 30°C for 24h. The product was washed with absolute ethanol until it was neutral, filtered to obtain a silica-coated nano-titanium dioxide filter cake, and then the filter cake was dried in a blast oven at 80°C for 24 hours, and ground to obtain a silica-coated nano-titanium dioxide powder .

[0071] Preparation of γ-aminopropyltrimethoxysilane-grafted silica-coated nano-titanium dioxide: Add 4g of silica-coated nano-titanium dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com