A kind of method that prepares polyhexamethylene monoguanidine hydrochloride by waste acid lye

A technology of polyhexamethylene monoguanidine hydrochloride and waste hydrochloric acid, which is applied in the field of sterilizing polymer preparation, can solve environmental pollution and other problems, and achieve the effects of high economic value, pollution reduction and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

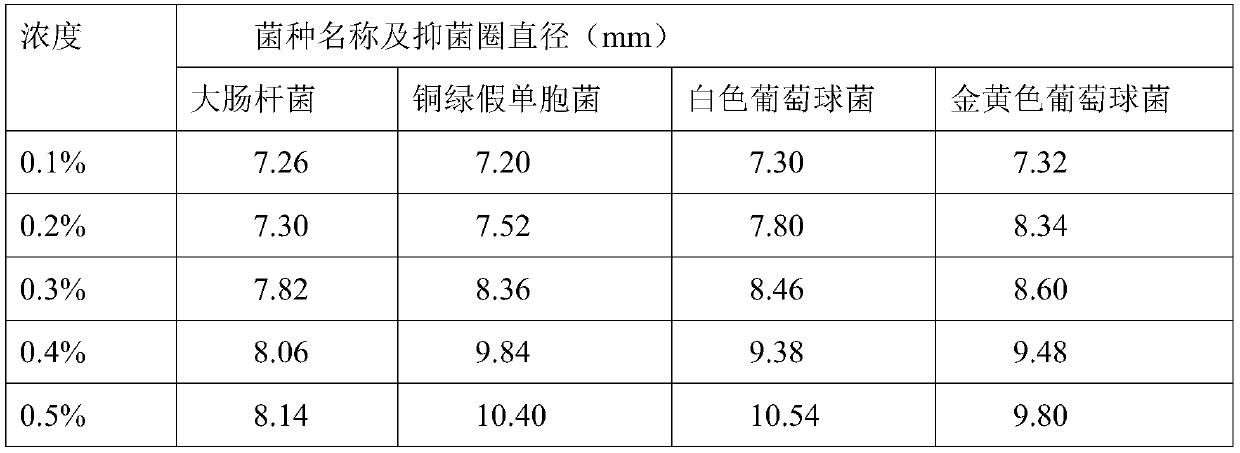

Image

Examples

Embodiment 1

[0024] Determination of the concentration of spent acid and alkali

[0025] 1) At first use 0.5mol / L hydrochloric acid standard solution and sodium hydroxide standard solution to carry out acid-base titration to waste liquid ammonia and waste hydrochloric acid solution, record the concentration of waste ammonia water to be 1.756mol / L, and the concentration of waste hydrochloric acid is 0.872mol / L. Among them, the waste ammonia water is prepared by absorbing the ammonia waste gas produced in the enterprise's production with deionized water; the waste hydrochloric acid is prepared by absorbing the hydrogen chloride waste gas produced in the enterprise's production with deionized water.

[0026] 2) Preparation of Ammonium Chloride

[0027] According to the volume ratio of 1:2, take 100mL of waste ammonia water and 200mL of waste hydrochloric acid solution, pour the waste ammonia solution into the waste hydrochloric acid solution, stir, and expose to the sun for a few days; or put...

Embodiment 2

[0037] The method for preparing polyhexamethylene monoguanidine hydrochloride by waste acid lye comprises the following steps:

[0038] 1) Preparation of ammonium chloride: use hydrochloric acid standard solution and sodium hydroxide standard solution to carry out acid-base titration to waste ammonia water and waste hydrochloric acid solution, record the concentration of waste ammonia water and waste hydrochloric acid, and then use a molar ratio of 1:1 to mix waste Slowly pour the ammonia solution into the waste hydrochloric acid solution; stir to obtain the ammonium chloride solution; the waste ammonia water is prepared by absorbing the ammonia waste gas produced in the production of the enterprise with deionized water; the waste hydrochloric acid is absorbed by the hydrogen chloride waste gas produced in the production of the enterprise with deionized water preparation.

[0039] 2) Place the ammonium chloride solution generated under the sun for a few days; or place the ammo...

Embodiment 3

[0043] The method for preparing polyhexamethylene monoguanidine hydrochloride by waste acid lye comprises the following steps:

[0044] 1) Preparation of ammonium chloride: use hydrochloric acid standard solution and sodium hydroxide standard solution to carry out acid-base titration of ammonia water and hydrochloric acid solution, measure the concentration of ammonia water and hydrochloric acid, then slowly pour the waste ammonia solution into In waste hydrochloric acid solution; Stir to obtain ammonium chloride solution;

[0045] 2) The ammonium chloride solution is placed on a heating plate to be heated and evaporated, and ammonium chloride crystals are separated out, filtered, and dried, and its purity is determined by the formaldehyde method, and the purity is 99.1%;

[0046]3) Feed the generated ammonium chloride, dicyandiamide, and hexamethylenediamine into the reactor at a molar ratio of 1.85:1:2, heat up under mechanical stirring, and react at 200°C until no ammonia g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com