Automatic suspension system, and control system and method of automobile suspension system

A technology of automobile suspension and control system, applied in the direction of suspension, elastic suspension, vehicle spring, etc., can solve the problem of high installation, manufacturing, maintenance costs, poor ride comfort, and invariable stiffness of shock absorber components and other problems, to achieve the effect of simple structure design, adjustable equivalent stiffness, and taking into account the handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

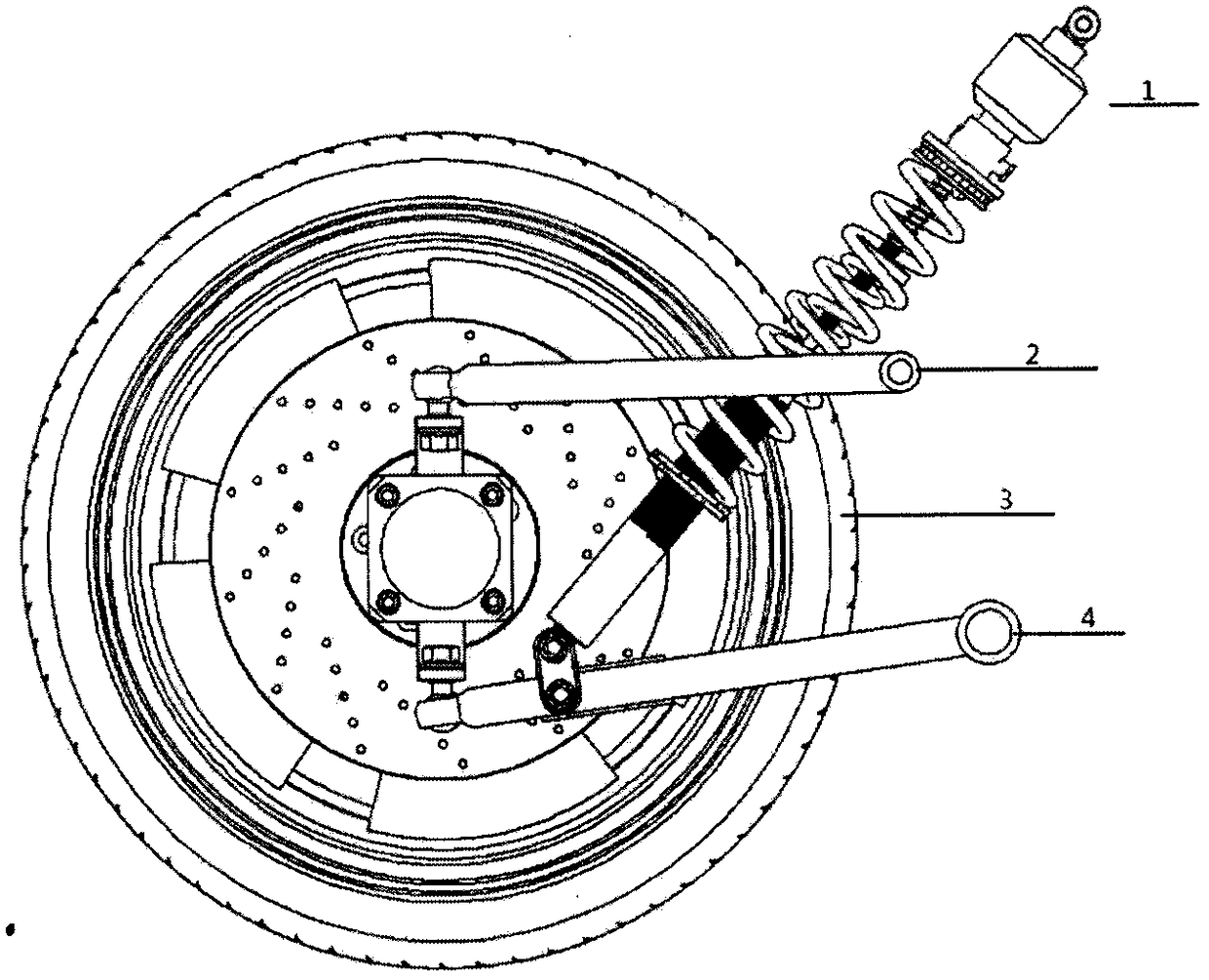

[0036] The invention provides a method to match the requirements of different driving conditions on maneuverability and smoothness by changing the spring stiffness, and at the same time, it has the functions of changing the height of the chassis of the car to improve the driving performance of the car under bad road conditions, and reducing the speed of the car when the car collides. An independent suspension for personal injury and a vehicle safety control system and method using the suspension to lift the chassis. Taking the double trailing arm independent suspension as an example and referring to the specific implementation mode of the accompanying drawings, the structure, function and control process of the suspension system are described in detail.

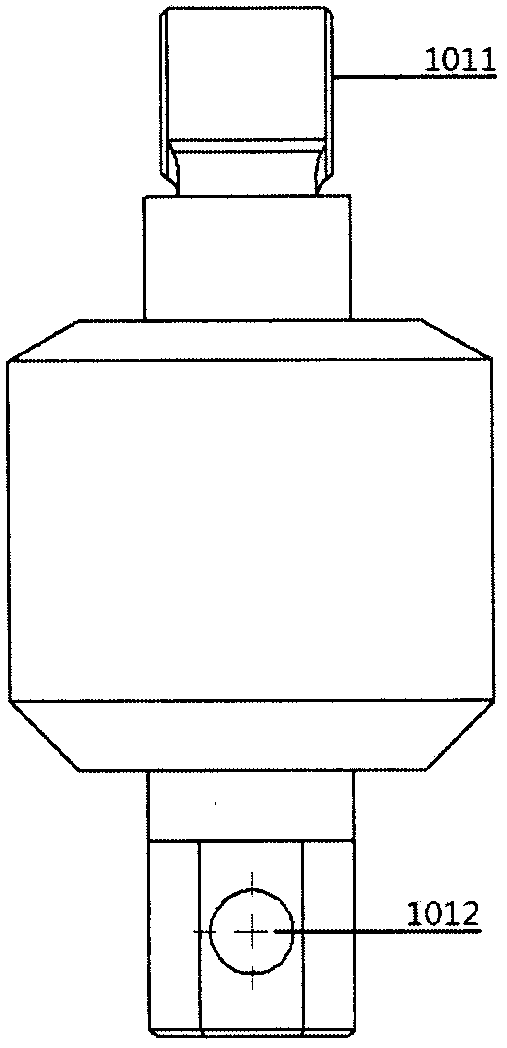

[0037] The technical solution of the present invention is: an independent suspension, comprising a shock absorber assembly assembly (1), an upper swing arm (2), a wheel assembly assembly (3), and a lower swing arm (4);

[0038...

Embodiment 2

[0050] The shock absorber assembly of the present invention is applied to the cross-arm type independent suspension, and the assembly style is as follows: Figure 7 and Figure 8 As shown, the hinge hole at the lower end of the shock absorber assembly is connected to the lower swing arm of the cross-arm suspension, and the hinge hole at the upper end of the shock absorber assembly is connected to the vehicle frame. The shock absorber assembly of the present invention can also be applied to multi-link independent suspension, Among the independent suspensions such as MacPherson independent suspension, the article only takes trailing arm independent suspension and cross arm independent suspension as implementation cases to describe its working principle and control method in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com