Graphite-metal frame composite bipolar plate and preparation method thereof

A metal frame, bipolar plate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of high cost and difficult surface modification of metal plates, and achieve enhanced bending strength, good electrical conductivity, and overall strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A preparation method of a graphite-metal frame composite bipolar plate:

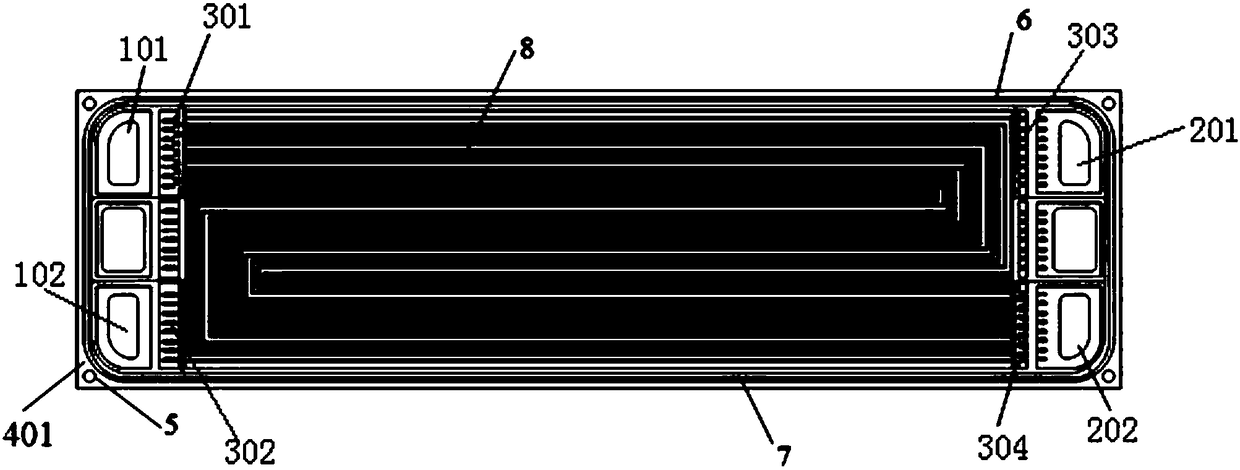

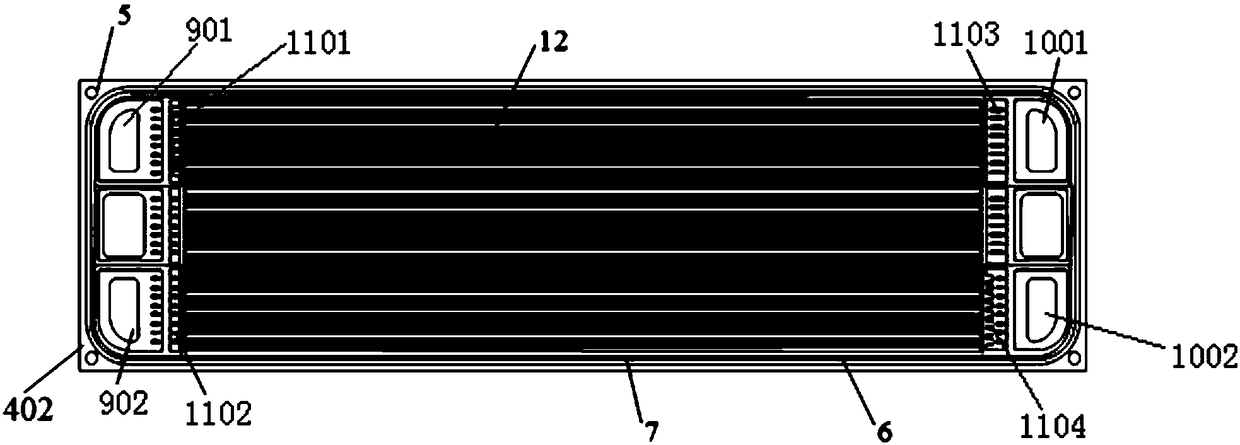

[0063] 1) Preparation of graphite plate: Add additives such as 65wt% artificial graphite, 20wt% phenolic resin, 15wt% carbon nanotubes and carbon black into a high-speed mixer for mixing, and the stirring time is 20min. Then, the mixture is put into a twin-screw extruder for kneading and granulation, and graphite plates with fuel flow channels 8 and oxidant flow channels 12 are prepared by extrusion and calendering, and the thickness of the graphite plate is 0.8 mm, the fuel flow channel and the oxidant flow channel are both concave and convex structures, the depth of the flow channel is 0.3mm, and the width is 1mm.

[0064] 2) Preparation of the metal frame of the anode plate: a 0.1 mm thick stainless steel 316 plate is stamped and formed in the mold, and the metal frame 401 of the stamped anode plate is distributed with the first fuel inlet 101, the second fuel inlet 102, the first fuel inlet 10...

Embodiment 2

[0068] A preparation method of a graphite-metal frame composite bipolar plate:

[0069] 1) Add additives such as 70wt% expanded graphite, 15wt% polypropylene, 15wt% carbon nanotubes and copper powder into a high-speed agitator for mixing, and the stirring time is 30min. Then, by molding the mixture, a graphite plate with a fuel flow channel 8 and an oxidant flow channel 12 is prepared respectively. The thickness of the graphite plate is 1.0 mm, and the fuel flow channel and the oxidizer flow channel are both concave and convex structures. The runner depth is 0.4mm and the width is 1mm.

[0070] 2) Preparation of the metal frame of the anode plate: the same as in Example 1, except that the stainless steel 316 plate with a thickness of 0.1 mm is replaced with a titanium alloy TC4 plate with a thickness of 0.2 mm.

[0071] 3) Preparation of the metal frame of the cathode plate: the same as in Example 1, except that the stainless steel 316 plate with a thickness of 0.1 mm is repl...

Embodiment 3

[0074] 1. Preparation of graphite-metal frame composite bipolar plate

[0075] 1) Add additives such as 75wt% natural graphite, 20wt% polyethylene, 10wt% carbon fiber and carbon black into a high-speed mixer for mixing, and the mixing time is 30min. Then, by injection molding the mixture, a graphite plate with a fuel flow channel 8 and an oxidant flow channel 12 is prepared respectively. The runner depth is 0.3mm and the width is 1mm.

[0076] 2) Preparation of the metal frame of the anode plate: the same as in Example 1, except that the stainless steel 316 plate with a thickness of 0.1 mm is replaced with a stainless steel 304 plate with a thickness of 0.2 mm.

[0077] 3) Preparation of the metal frame of the cathode plate: the same as in Example 1, except that the stainless steel 316 plate with a thickness of 0.1 mm is replaced with a stainless steel 304 plate with a thickness of 0.2 mm.

[0078] Step 4) is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com