The production process of abamectin

A production process and seed technology, which is applied in the field of abamectin fermentation production, can solve the problems of poor oxygen dissolution in the medium, high wastewater COD, low starch utilization rate, etc., achieve significant production advantages, reduce wastewater COD, improve dissolution The effect of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

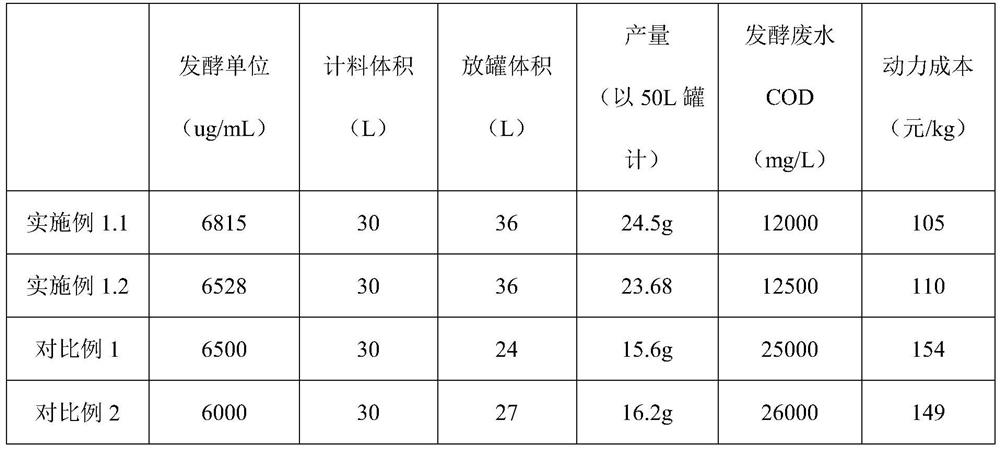

Examples

Embodiment 1

[0019] Present embodiment relates to a kind of production technology of Abamectin.

Embodiment 11

[0021] The production of Abamectin comprises the following steps:

[0022] a, shaking flask seed culture: by weight percentage with glucose 1.5%, corn steep liquor 0.3%, yeast extract 0.5%, calcium carbonate 0.1%, the remainder is tap water, and adjust pH7.0 configuration seed culture medium, after sterilizing and cooling , inoculate the grown Streptomyces avermitilis spores in the seed medium under aseptic conditions, and culture and grow the shake flask at 28±1°C for 24 hours to obtain the shake flask seed liquid;

[0023] B, seed tank cultivation: inoculate the shake flask seed liquid of step a into the seed tank, by weight percentage with glucose 2%, corn steep liquor 0.8%, yeast extract 0.3%, calcium carbonate 0.2%, surplus is tap water, and adjusts pH7 .2 Configure the seed medium in the seed tank, the inoculation amount is 0.1% of the volume of the seed medium, cultivate and grow at 28±1°C for 24-28 hours to obtain the seed liquid;

[0024] C, fermentation tank culture...

Embodiment 12

[0028] The production of Abamectin comprises the following steps:

[0029] a, shaking flask seed culture: by weight percentage with glucose 2%, corn steep liquor 0.5%, yeast extract 0.5%, calcium carbonate 0.1%, the remainder is tap water, and adjust pH7.0 configuration seed culture medium, after sterilizing and cooling , inoculate the grown Streptomyces avermitilis spores in the seed medium under aseptic conditions, and culture and grow the shake flask at 28±1°C for 28 hours to obtain the shake flask seed liquid;

[0030] B, seed tank cultivation: inoculate the shake flask seed solution of step a into the seed tank, use glucose 2% by weight percentage, corn steep liquor 0.5%, yeast extract 0.5%, calcium carbonate 0.2%, surplus is tap water, and adjust pH7 .2 Configure the seed medium in the seed tank, the inoculation amount is 0.1% of the volume of the seed medium, and cultivate and grow at 28±1°C for 24-28 hours to obtain the seed liquid;

[0031] C, fermentation tank cultu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com