Copper bar and aluminum bar connecting method and device for battery

A connection method and a technology of a connection device, which are applied to battery pack components, circuits, electrical components, etc., to achieve the effects of ensuring stability, simple molding, and facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to a method for connecting battery copper bars and aluminum bars described in this embodiment, at least one layer of inert metal layer is bonded to the outer surfaces of the copper bars and aluminum bars to be connected by hot pressing. , the inert metal layer of the copper row is closely attached to the inert metal layer of the aluminum row.

[0030] Specifically, when the power battery is connected, the connection between the copper bar and the aluminum bar is usually directly connected, or copper-aluminum composite material is used for connection, or nickel is plated on the copper bar and the aluminum bar. Chemical corrosion, collapse of aluminum row, etc. In the present invention, at the position where the copper row and the aluminum row are connected, at least one layer of inert metal layer is directly bonded through a hot pressing process. Preferably, only one layer is used when connecting the copper row and the aluminum row. The inert metal layer conne...

Embodiment 2

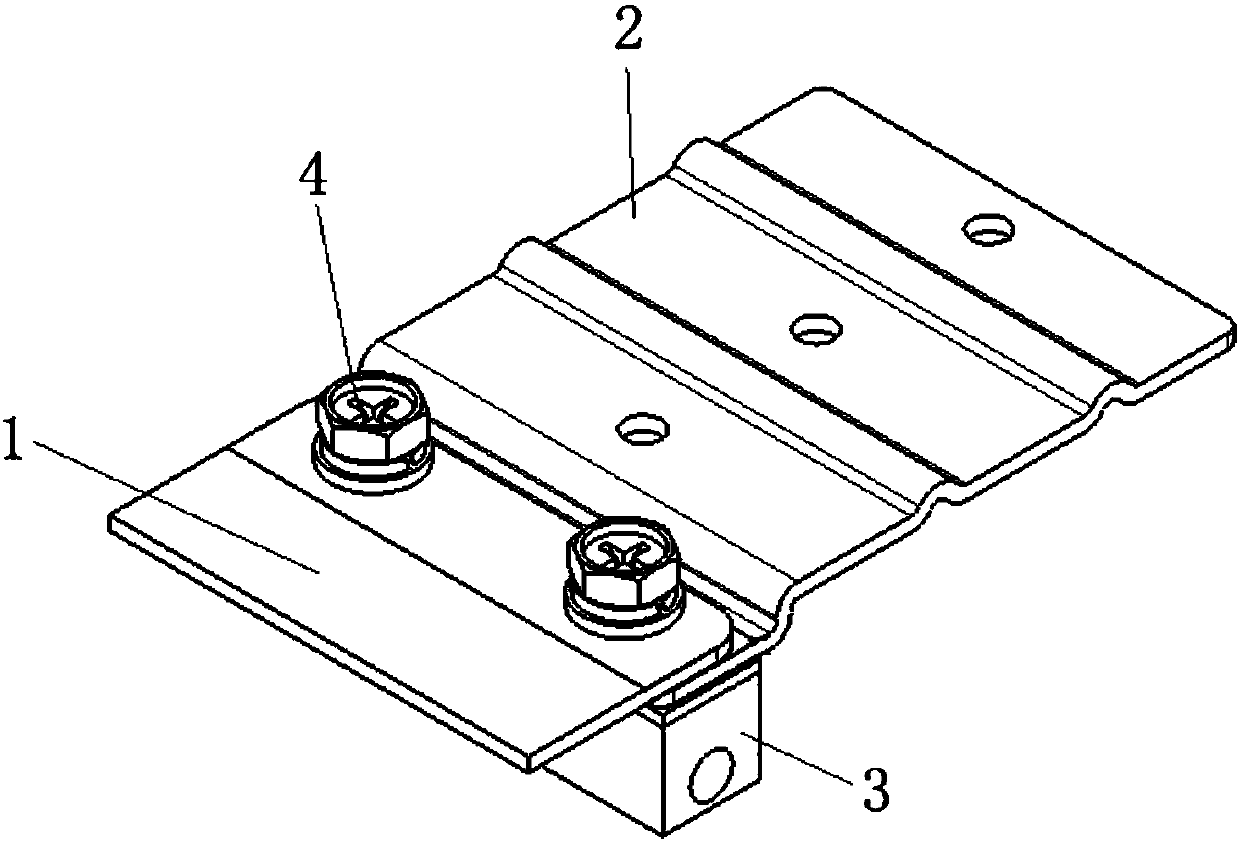

[0033] Such as figure 1 As shown, a battery copper bar and aluminum bar connection device described in this embodiment is prepared by the method of the first embodiment above, wherein the connection device includes copper sheets, aluminum bars 2, spacers 3, copper sheets and The aluminum row 2 is connected and fixed on the pad 3, and a layer of nickel layer is bonded to the outer surface of the connection between the copper row 1 and the aluminum row 2. When connecting, the nickel layers of the copper row 1 and the aluminum row 2 are closely attached to each other. The copper sheet and the aluminum row 2 are fixed on the pad 3 by bolts, the pad 3 is provided with screw holes, the copper row 1 and the aluminum row 2 are provided with alignment screw holes, the pad 3 is an aluminum pad 3, and the copper row 1 The connection is completed by fixing the aluminum row 2 to the aluminum spacer 3 through the Phillips screw 4. In order to ensure the stable connection of the spacer 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com