Preparation method and applications of nitrogen doped carbon particle/graphitized carbon-nitrogen composite material

A technology of composite materials and graphitized carbon, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of poor electrochemical energy storage properties, small specific surface area of pure graphitized carbon and nitrogen sheets, etc., achieve high nitrogen doping amount, and benefit materials Electric double layer capacitance and pseudocapacitance, effects suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Zn(NO 3 ) 2 (100 mmol L -1 , 15 mL) and MIM (100 mmol L -1 , 30 mL) of methanol solution were mixed and stirred at room temperature for 12 h, the product was collected by centrifugation, washed with methanol, and dried in an oven at 60 °C to obtain ZIF-8 crystals;

[0031] (2) The ZIF-8 crystal prepared in step (1) was raised to 800 °C at a heating rate of 2 °C / min in a tube furnace under a nitrogen atmosphere, and calcined at this temperature for 3 h;

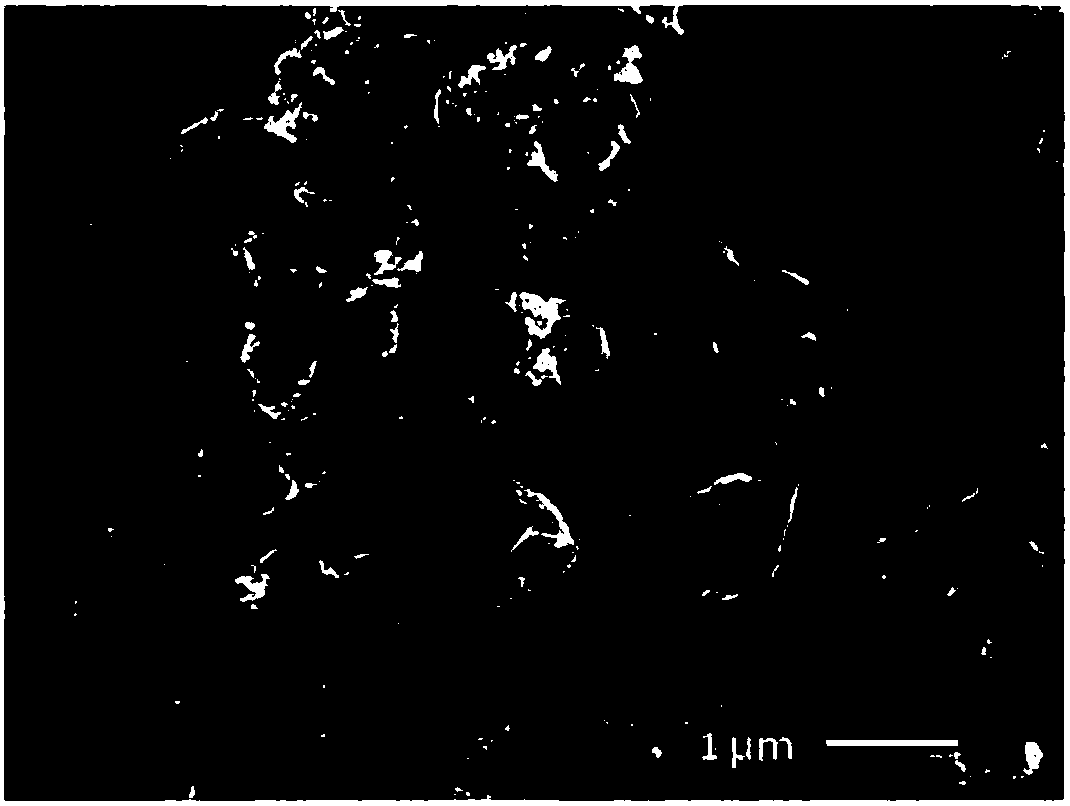

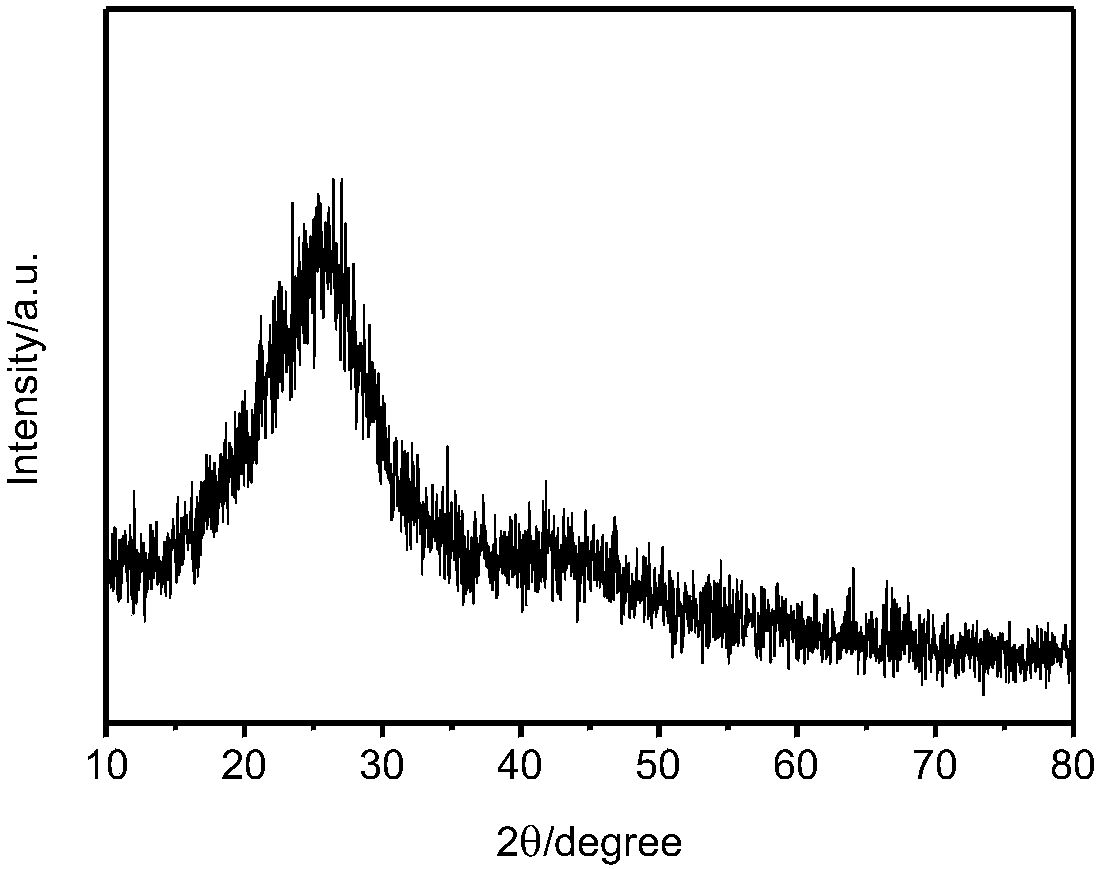

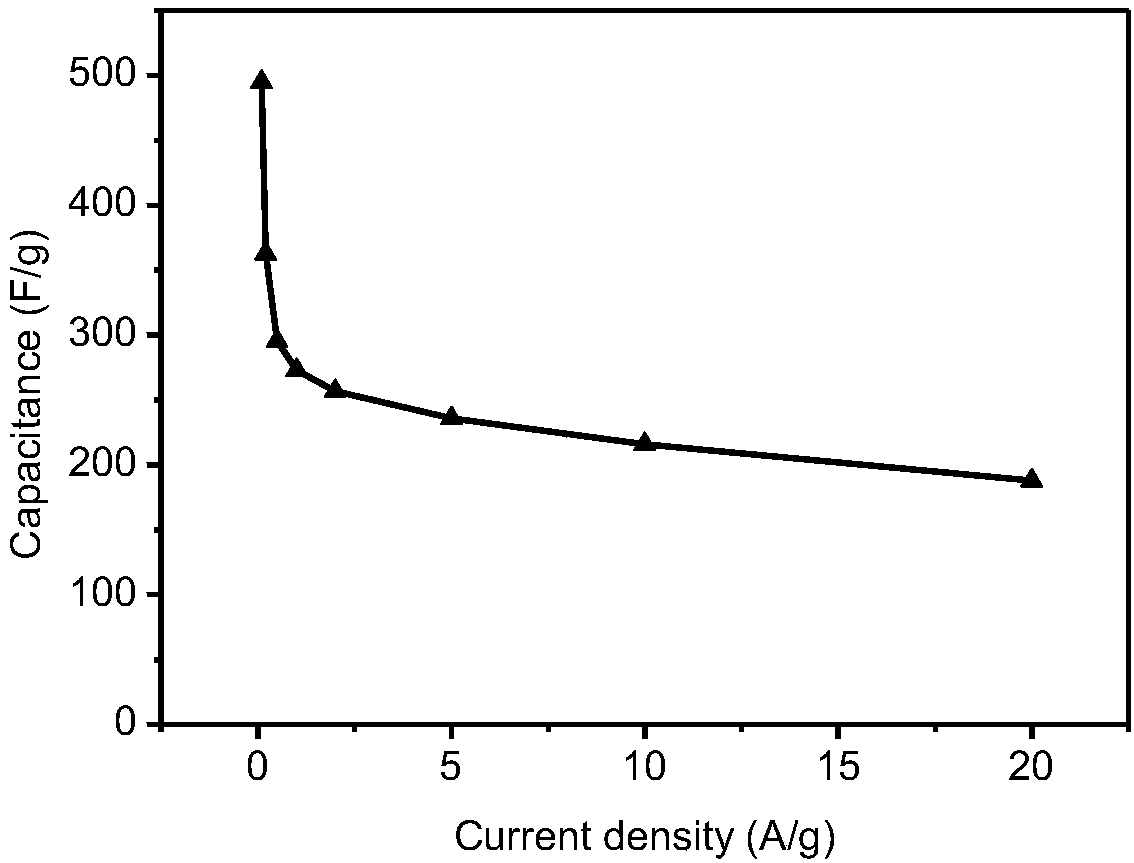

[0032] (3) Mix the zinc-nitrogen-doped carbon particles (Zn-NCPs, 0.1 g) prepared in step (2) with 10 g urea and 0.5 g glucose, and then grind them thoroughly. In the muffle furnace, the temperature was raised to 550°C at a rate of 2°C / min, and calcined at this temperature for 3 h to obtain product A; then the calcined product A was transferred to a tube furnace, and under a high-temperature nitrogen atmosphere, the The heating rate was increased to 800°C at a rate of 3°C / min, and calcined at this temperature fo...

Embodiment 2

[0038] (1) Zn(NO 3 ) 2 (100 mmol L -1 , 15 mL) and MIM (100 mmol L -1 , 30 mL) of methanol solution were mixed and stirred at room temperature for 12 h, the product was collected by centrifugation, washed with methanol, and dried in an oven at 60 °C to obtain ZIF-8 crystals;

[0039] (2) The ZIF-8 crystal prepared in step (1) was raised to 800°C at a heating rate of 2°C / min in a tube furnace under a nitrogen atmosphere, and calcined at this temperature for 3 h;

[0040] (3) Mix the zinc-nitrogen-doped carbon particles (Zn-NCPs, 0.05 g) prepared in step (2) with 10 g urea and 0.5 g glucose and grind them thoroughly. In the muffle furnace, the temperature was raised to 550°C at a rate of 2°C / min, and calcined at this temperature for 3 h to obtain product A; then the calcined product A was transferred to a tube furnace, and under a high-temperature nitrogen atmosphere, the The temperature was raised to 800°C at a rate of 3°C / min, and calcined at this temperature for 1 h to ob...

Embodiment 3

[0043] (1) Zn(NO 3 ) 2 (100 mmol L -1 , 15 mL) and MIM (100 mmol L -1 , 30 mL) of methanol solution were mixed and stirred at room temperature for 12 h, the product was collected by centrifugation and washed with methanol, dried in an oven at 60 °C to obtain ZIF-8 crystals;

[0044] (2) The ZIF-8 crystal prepared in step (1) was raised to 800°C at a heating rate of 2°C / min in a tube furnace under a nitrogen atmosphere, and calcined at this temperature for 3 h;

[0045] (3) The zinc-nitrogen-doped carbon particles (Zn-NCPs, 0.2 g) prepared in step (2) were mixed with 10 g urea and 0.5 g glucose and then fully ground. In the muffle furnace, the temperature was raised to 550°C at a rate of 2°C / min, and calcined at this temperature for 3 h to obtain product A; then the calcined product A was transferred to a tube furnace, and under a high-temperature nitrogen atmosphere, the The temperature was raised to 800°C at a rate of 3°C / min, and calcined at this temperature for 1 h to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com