Fluorescent sensor for detecting inorganic pyophosphatase and its preparation method

A technology of inorganic pyrophosphatase and fluorescent sensor, applied in chemical instruments and methods, fluorescence/phosphorescence, instruments, etc., can solve the problems of low fluorescence intensity, time-consuming process, expensive instruments, etc., and achieve the effect of efficient detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

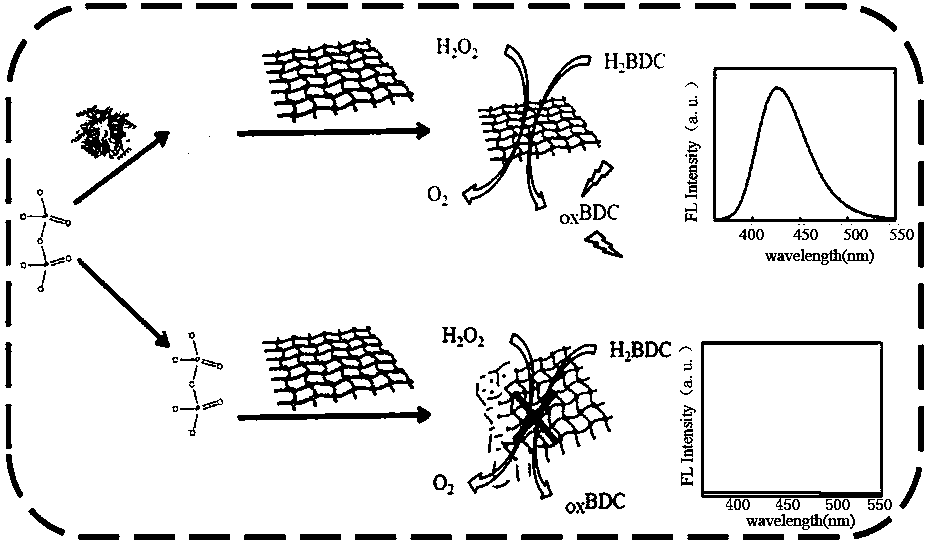

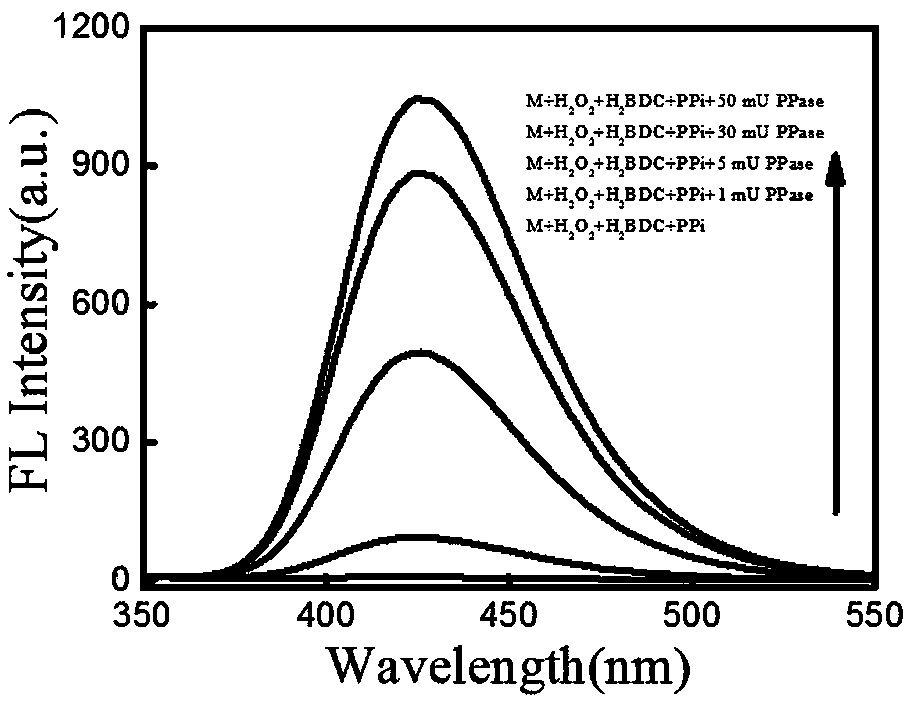

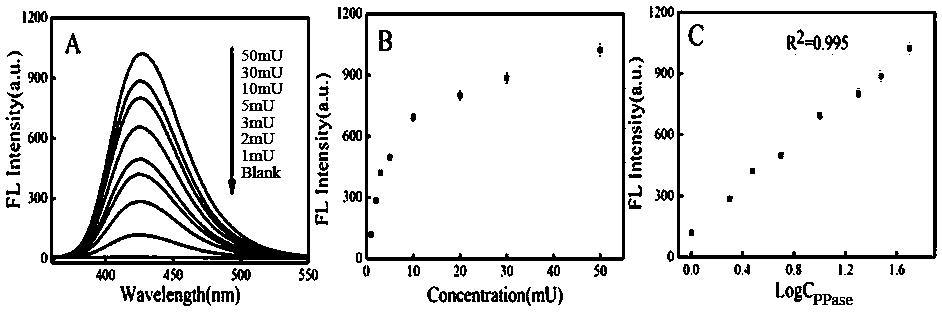

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a fluorescent sensor for detecting inorganic pyrophosphatase, comprising the following steps:

[0035] 1) Prepare inorganic pyrophosphatase solutions with different concentration units;

[0036] 2) Disperse the two-dimensional metal-organic framework Cu-BDC-MOF nanosheets with simulated enzyme activity in ultrapure water and sonicate for 30 min, centrifuge to take the supernatant for later use; the Cu-BDC-MOF nanosheets in the supernatant The concentration is 200 mg / mL;

[0037] 3) Dissolve sodium pyrophosphate in tris(hydroxymethyl)aminomethane-hydrochloride buffer solution to prepare sodium pyrophosphate solution, store at 4°C for later use;

[0038] 4) Dilute 60 times with 30% hydrogen peroxide solution and store at 4°C for later use;

[0039] 5) Dissolve terephthalic acid in tris(hydroxymethyl)aminomethane-hydrochloric acid buffer to prepare a terephthalic acid solution, and store it in the dark at 4°C for later use;

[0040] 6) Take 20 μL ...

Embodiment 1

[0050] A method for preparing a fluorescent sensor for detecting inorganic pyrophosphatase, the specific steps are:

[0051] 1. Prepare inorganic pyrophosphatase solutions with different concentration units;

[0052] 2. First synthesize Cu-BDC-MOF nanosheet material, the steps are as follows:

[0053] 1) Dissolve 3.0 mg of terephthalic acid in 3.0 mL of a mixed solvent of N,N-dimethylformamide and acetonitrile with a volume ratio of 2:1;

[0054] 2) Dissolve 3.0 mg of copper nitrate trihydrate in 3.0 mL of a mixed solvent of N,N-dimethylformamide and acetonitrile with a volume ratio of 1:2;

[0055] 3) Prepare 2.0 mL of a mixed solvent of N,N-dimethylformamide and acetonitrile with a volume ratio of 1:1 as the linking solution;

[0056] 4) First add terephthalic acid solution into a test tube with a diameter of 2.0 cm and a capacity of 30 mL, then add 2.0 mL of connecting solution, and finally add copper nitrate solution; Heated and reacted for 36 hours; the blue product wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com