Flushing device and water feeding start control mechanism thereof

A technology of starting control and starting mechanism, applied in the field of bathroom, can solve problems such as inability to realize, and achieve the effects of reliable function, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0064] (one end of the rotating arm 32 of the start switch is linked with the seal assembly 21, and the other end is linked with the water stop assembly 11)

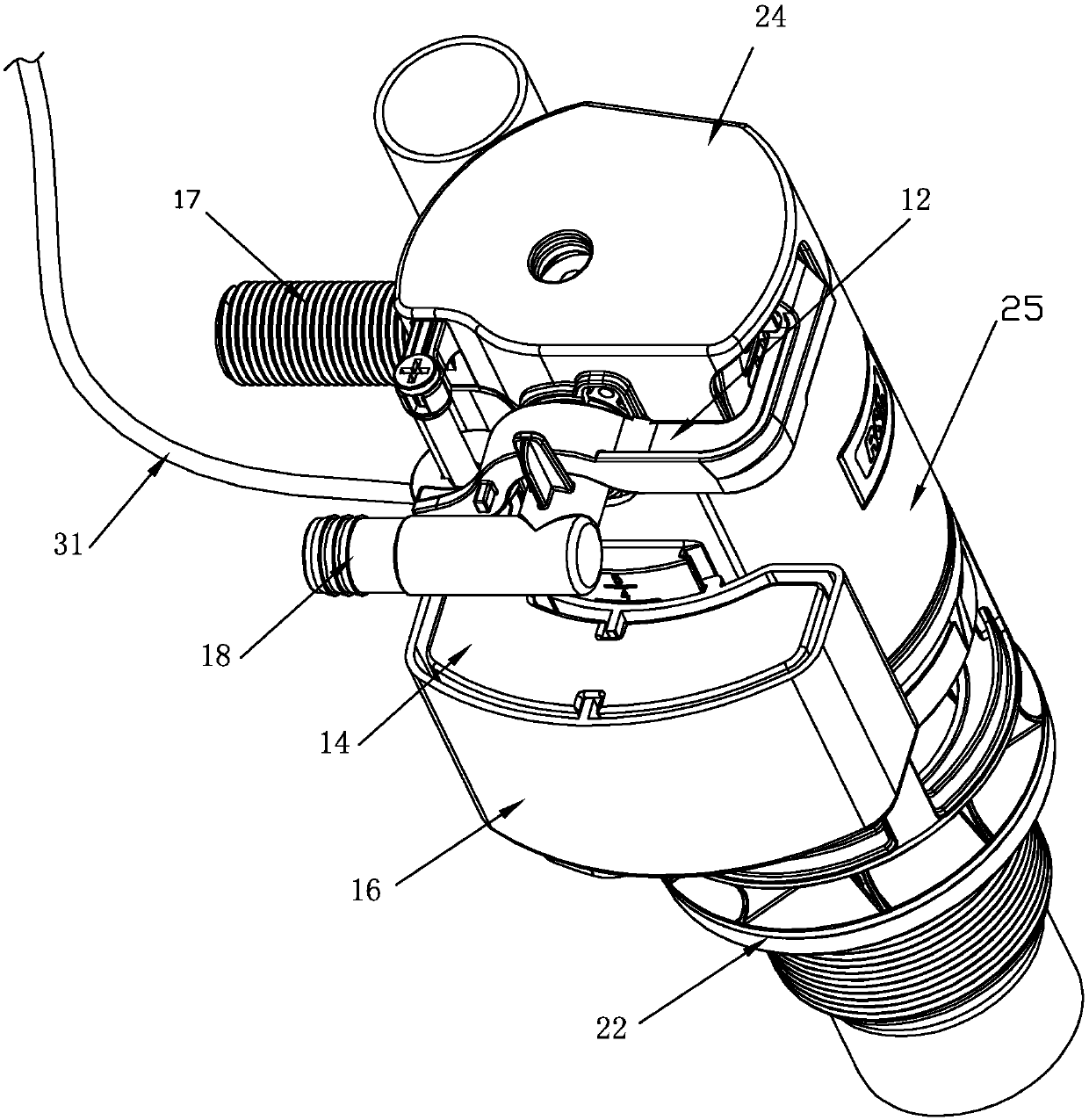

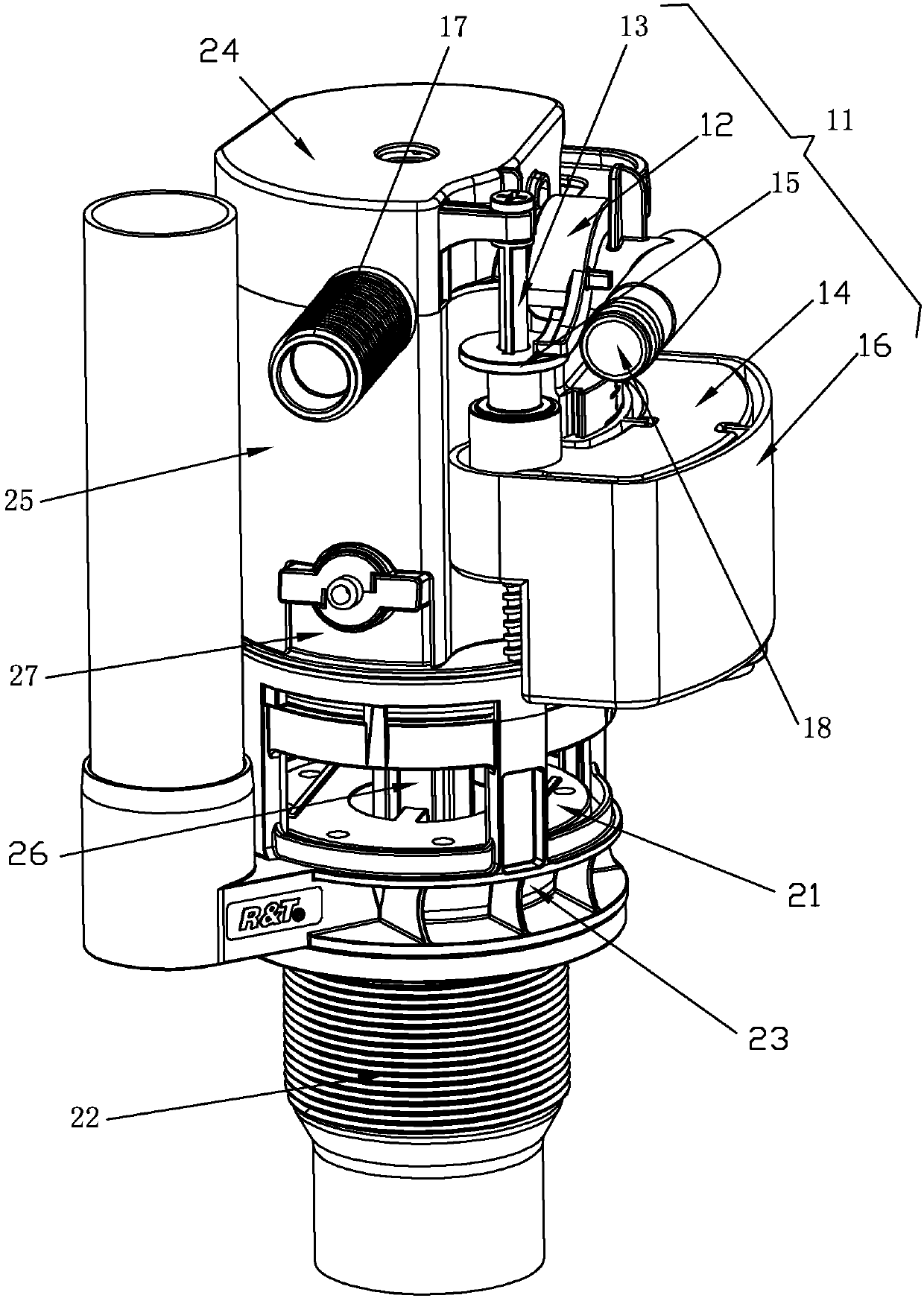

[0065] like Figures 1 to 15 As shown, in this embodiment, the starting mechanism includes a starting switch, the starting switch is linked with the sealing assembly 21 and opens the water tank drain 23, and the starting switch drives the water-stopping assembly 11 through a connecting rod 33 Move to connect the water inlet channel 17 and the water outlet channel 18 of the water inlet mechanism. Wherein, the start switch includes a wire rope 31 and a rotating arm 32 .

[0066] Rotating arm 32:

[0067] like Figure 14 As shown, the rotating arm 32 is provided with a connection point 321 with a wire rope, a connection point 322 with a connecting rod, and a pivot point 323 with the lifting arm 35; one end of the rotating arm 32 rotates under the traction of the wire rope 31 and The sealing assembly 21 is lifted to open...

no. 2 example

[0074] (One end of the rotating arm 32 of the start switch is linked with the seal assembly 21, and then the seal assembly 21 is linked with the water stop assembly 11)

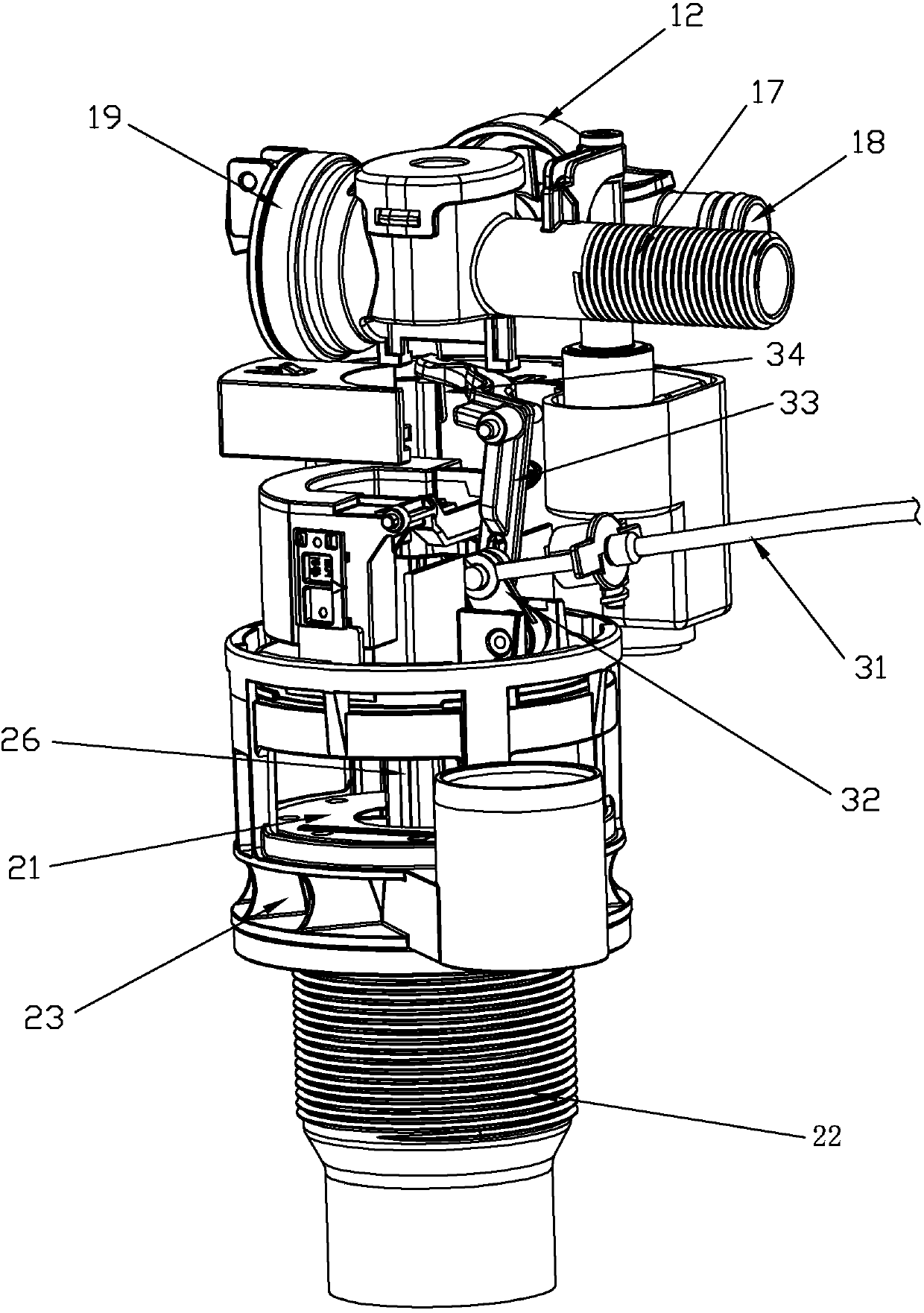

[0075] like Figures 16 to 18 As shown, the main difference between this embodiment and the first embodiment is that the starting switch is linked with the sealing assembly 21 and opens the water tank drain 23, the starting switch includes a steel wire rope 31 and a rotating arm 32, and the rotating arm 32 One end rotates under the traction of the steel wire rope 31 and lifts the sealing assembly 21. The connecting rod 33 is rotatably mounted on the drainage body 27 above the valve stem 26. When the sealing assembly 21 is lifted, the linkage The connecting rod 33 rotates, and then drives the movement of the water-stop assembly 11. Specifically, the sealing assembly 21 lifts the valve stem 26 and pushes up against one end of the connecting rod 33 to rotate the connecting rod 33. The other end of the connecting...

no. 3 example

[0080] like Figures 19 to 20 As shown, the difference between this embodiment and the above-mentioned second embodiment is that a boss 261 is provided above the valve stem 26. When the sealing assembly 21 is not lifted, the top surface of the boss 261 abuts against one end of the connecting rod 33, sealing When the assembly 21 is lifted, the valve rod 26 of the sealing assembly 21 pushes upward against one end of the connecting rod 33 so that the connecting rod 33 rotates, and then the one end of the connecting rod 33 is separated from the top surface of the boss 261 and abuts against the side of the boss 261, Compared with the above-mentioned second embodiment, the advantage of setting the boss 261 is that it prevents one end of the connecting rod 33 from still abutting against the top of the valve rod 26 after the connecting rod rotates, causing the valve rod 26 to be pushed downward by one end of the connecting rod 33. The reaction force is large, which leads to the proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com