Truss truck robot integration system

An integrated system and robot technology, applied in the field of truss robot integrated system, can solve the problems of reducing production tempo, increasing equipment manufacturing cost, and not being able to accurately transport specific workpieces, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of a truss car robot integration system of the present invention will be described in detail below in conjunction with the accompanying drawings.

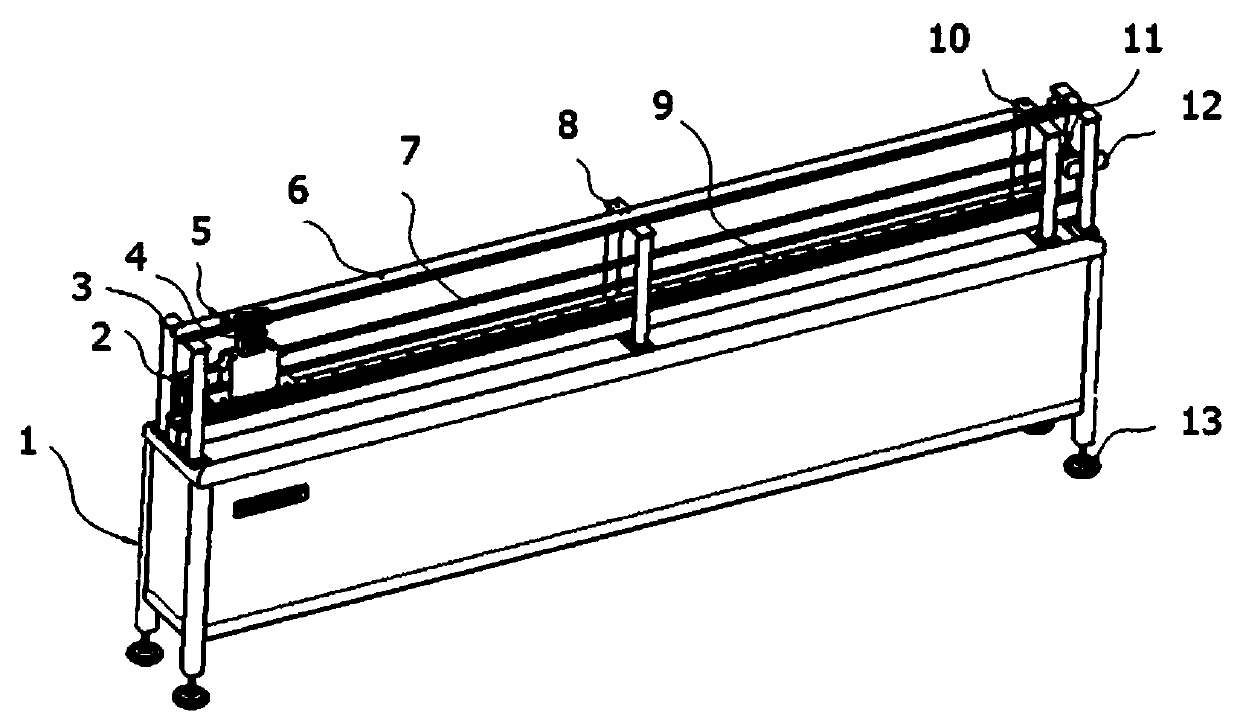

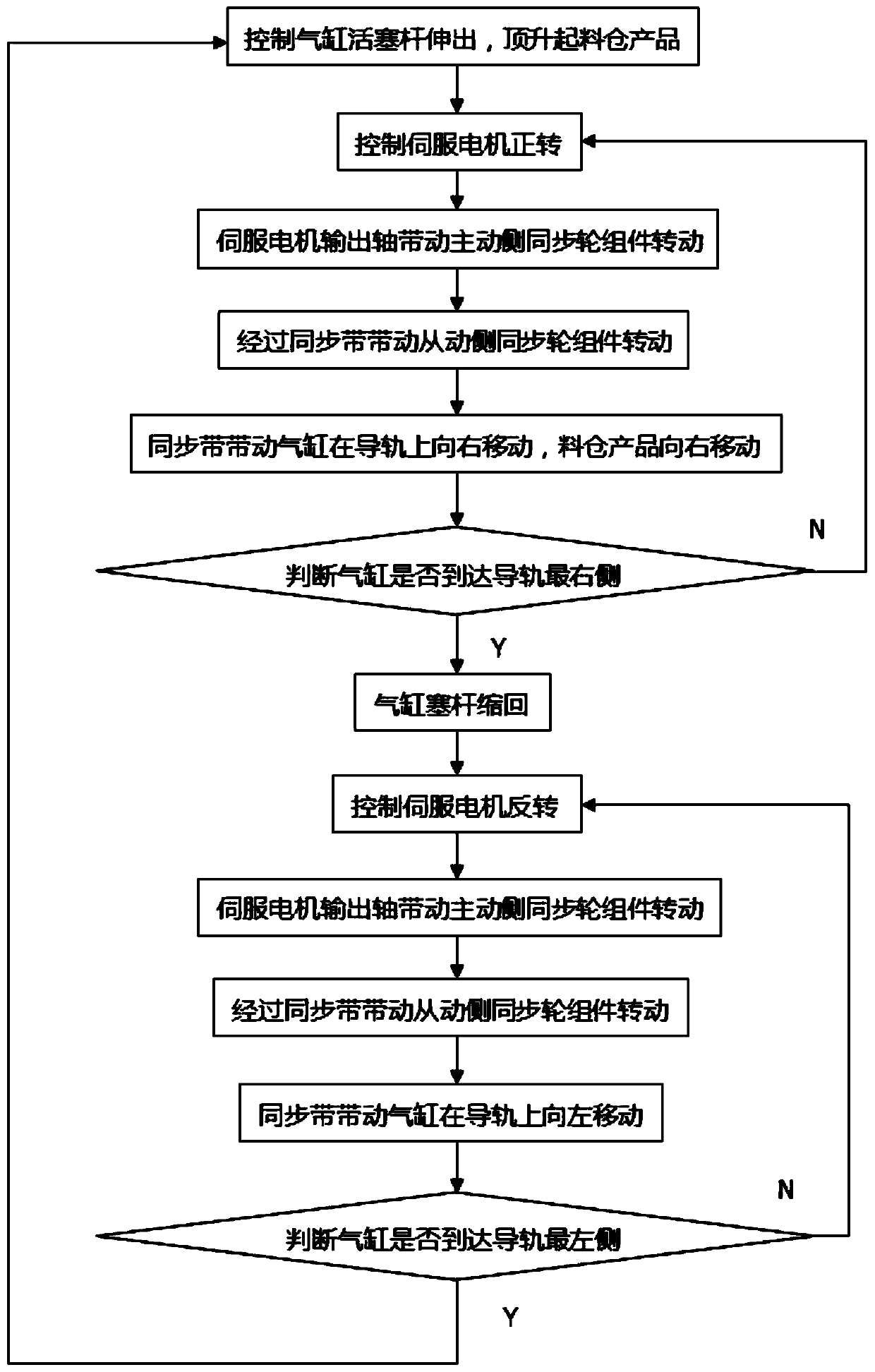

[0021] Such as figure 1 As shown, the truss car robot integrated system of the present invention includes a frame 1, a driven side synchronous wheel assembly 2, a cylinder 4, a shift fork 5, a bin 6, a synchronous belt 7, a guide rail 9, a first bracket 3, and a second bracket 8. The third bracket 10, the active side synchronous wheel assembly 11, the servo motor 12 and the foot cup 13, the frame 1 is installed on the foot cup 13, the first bracket 3, the second bracket 8, the third bracket 10, and the guide rail 9 respectively Installed on the frame 1, the servo motor 12 is installed on the guide rail 9, the output shaft of the servo motor 12 is connected with the driving side synchronous wheel assembly 11, and the driving side synchronous wheel assembly 11 and the driven side synchronous wheel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com