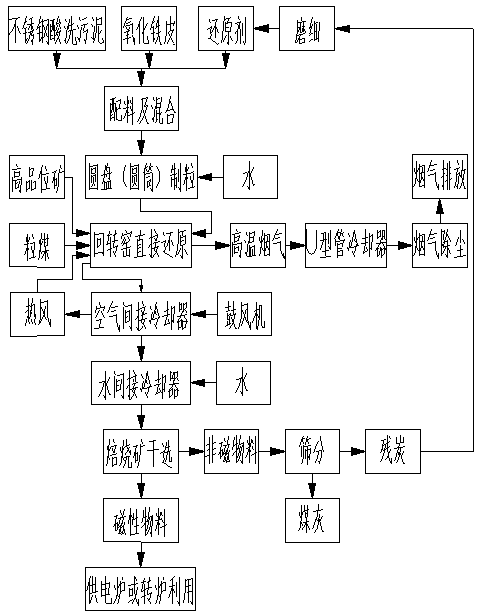

Stainless steel acid pickling sludge treatment process

A technology for pickling sludge and treatment process, applied in the furnace type, solid separation, furnace and other directions, can solve the problem of low melting temperature of pickling sludge, unfavorable direct reduction of pickling sludge, and inability to produce metallization rate reduction materials, etc. problems, to achieve the effect of shortening the reduction time, efficient utilization, and reducing the reduction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A stainless steel pickling sludge treatment process, the specific process is as follows:

[0043] 1. Selection of materials

[0044] Stainless steel pickling sludge: iron grade 12%, SiO 2 Mass content 7%, Cr 2 o 3 The mass content is 3%, and the Ni mass content is 1%.

[0045] Stainless steel oxide scale: iron grade is 50%, Cr 2 o 3 The mass content is 15%, and the Ni mass content is 1%.

[0046] High volatile granular coal: 44% fixed carbon mass content, 9% ash mass content, 49% volatile matter mass content, and 20mm particle size.

[0047] High-grade hematite: Fe grade is 47%, particle size is 1mm.

[0048] 2. Material granulation

[0049] Stainless steel pickling sludge, iron oxide scale and reduced coal are batched and mixed according to the mass ratio of 50:50:20 to obtain mixed raw materials. The mixed raw materials are made into granular materials with a water content of 10% and a particle size of 5mm by a disc granulator. The reduced coal is ground to 2...

Embodiment 2

[0060] A stainless steel pickling sludge treatment process, the specific process is as follows:

[0061] 1. Selection of materials

[0062] Stainless steel pickling sludge: iron grade 16%, SiO 2 Mass content 5%, Cr 2 o 3 The mass content is 4%, and the Ni mass content is 2%.

[0063] Stainless steel oxide scale: iron grade is 56%, Cr 2 o 3 The mass content is 28%, and the Ni mass content is 9%.

[0064] High volatile granular coal: 46% fixed carbon mass content, 7% ash mass content, 47% volatile matter mass content, and 5mm particle size.

[0065] High-grade hematite: the iron grade is 48%, and the particle size is 10mm.

[0066] 2. Material granulation

[0067] Stainless steel pickling sludge, iron oxide scale and reduced coal are batched and mixed according to the mass ratio of 50:50:10 to obtain mixed raw materials. The mixed raw materials are made into granular materials with a water content of 12% and a particle size of 3mm by a cylinder granulator. The reduced c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com