Synthetic method of benzyl benzoate

A technology of benzyl benzoate and a synthesis method, applied in the synthesis field of benzyl benzoate, can solve problems such as high reaction temperature, large catalyst, high production cost, achieve high reaction conversion rate and selectivity, reduce production cost, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

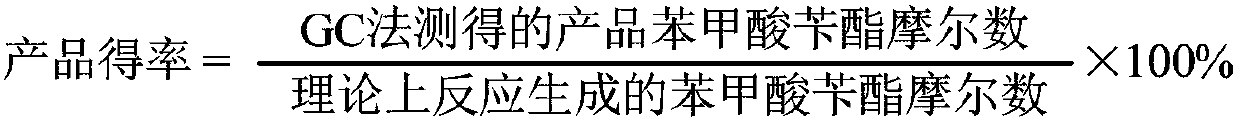

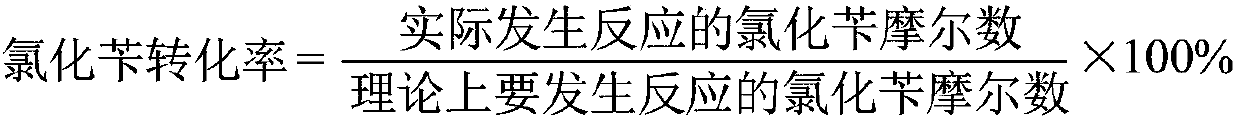

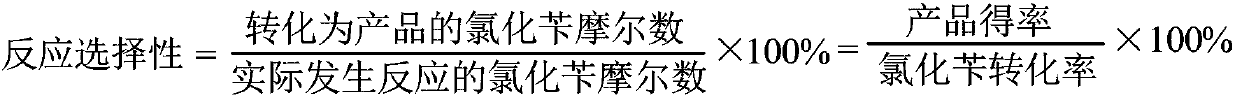

Examples

Embodiment 1

[0023] A method for synthesizing benzyl benzoate through uncatalyzed esterification: 67.17g (550mmol) sodium benzoate, 63.29g (500mmol) benzyl chloride, 200mL N,N‐dimethylformamide are added in a three-necked flask, and heated at 80°C The next reaction. The reaction system was white and turbid at the beginning, and the reaction solution gradually became clear as the heating and stirring proceeded. Keep the reaction at 80°C. As the reaction progresses, white sodium chloride solids precipitate out in the reaction solution, and the reaction ends after 1.5 hours. After the reaction solution was cooled to room temperature, the Buchner funnel was suction-filtered, and the filtrate was collected. After distillation under reduced pressure, the solvent N, N-dimethylformamide was distilled off and the solution was in a white milky state. The separated sodium benzoate solid is separated by filtration, and the filtrate is removed by distillation and rectification to remove low-boilers a...

Embodiment 2

[0025] A method for synthesizing benzyl benzoate through uncatalyzed esterification: 91.59g (750mmol) sodium benzoate, 63.29g (500mmol) benzyl chloride, and 300mL toluene are added in a three-necked flask and reacted at 90°C. The reaction system was white and turbid at the beginning, and the reaction solution gradually became clear as the heating and stirring proceeded. The reaction was kept at 90°C. As the reaction progressed, white sodium chloride solids precipitated out in the reaction solution, and the reaction ended after 1 hour. After the reaction solution was cooled to room temperature, the Buchner funnel was suction-filtered, and the filtrate was collected. Distilled under reduced pressure, after the solvent toluene was distilled off, the solution was in a white milky state. The separated sodium benzoate solid is separated by filtration, and the filtrate is removed by distillation and rectification to remove low-boilers and high-boilers in the product to obtain the fi...

Embodiment 3

[0027] A method for synthesizing benzyl benzoate through uncatalyzed esterification: 109.91g (900mmol) sodium benzoate, 75.94g (600mmol) benzyl chloride, and 500mL chloroform are added in a three-necked flask, heated to reflux. The reaction system was white and turbid at the beginning, and the reaction solution gradually became clear as the heating and stirring proceeded. Keep reflux, along with the progress of the reaction, there is white sodium chloride solid to separate out in the reaction solution, and the reaction ends after 2 hours. After the reaction solution was cooled to room temperature, the Buchner funnel was suction-filtered, and the filtrate was collected. Distilled under reduced pressure, the solvent chloroform was distilled off, and the solution was in a white milky state. The separated sodium benzoate solid is separated by filtration, and the filtrate is removed by distillation and rectification to remove low-boilers and high-boilers in the product to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com