Preparation method of a variety specifications of dementholized peppermint oil and menthol by combined azeotropic distillation and vacuum distillation technology

A technology of vacuum distillation and mint oil, which is applied in the preparation of hydroxyl compounds, organic compounds, essential oils/fragrances, etc., can solve the problems of large fraction loss, influence of vegetable oil aroma, high distillation temperature, etc., to ensure quality and reduce loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Get 400g of peppermint hair oil, after adding 200g of entrainer water, carry out azeotropic rectification under the conditions of -0.06MPa in the height of packing column 1.0m, reflux ratio 3:1, vacuum degree, separate the cut before, detect, when cut When the content of olefins in the medium is ≤1%, stop. Oil and water are separated, and the oil phase is to be treated. The oil phase of the above-mentioned fraction before removal was obtained by rectification under reduced pressure under the conditions of packing column height 1.0m, reflux ratio 3:1, vacuum degree -0.096MPa, and detection, when the L-menthol content in the fraction was ≥50 %, stop. Add 150 g of water to the oil phase, and steam distillation under normal pressure to obtain the rear fraction.

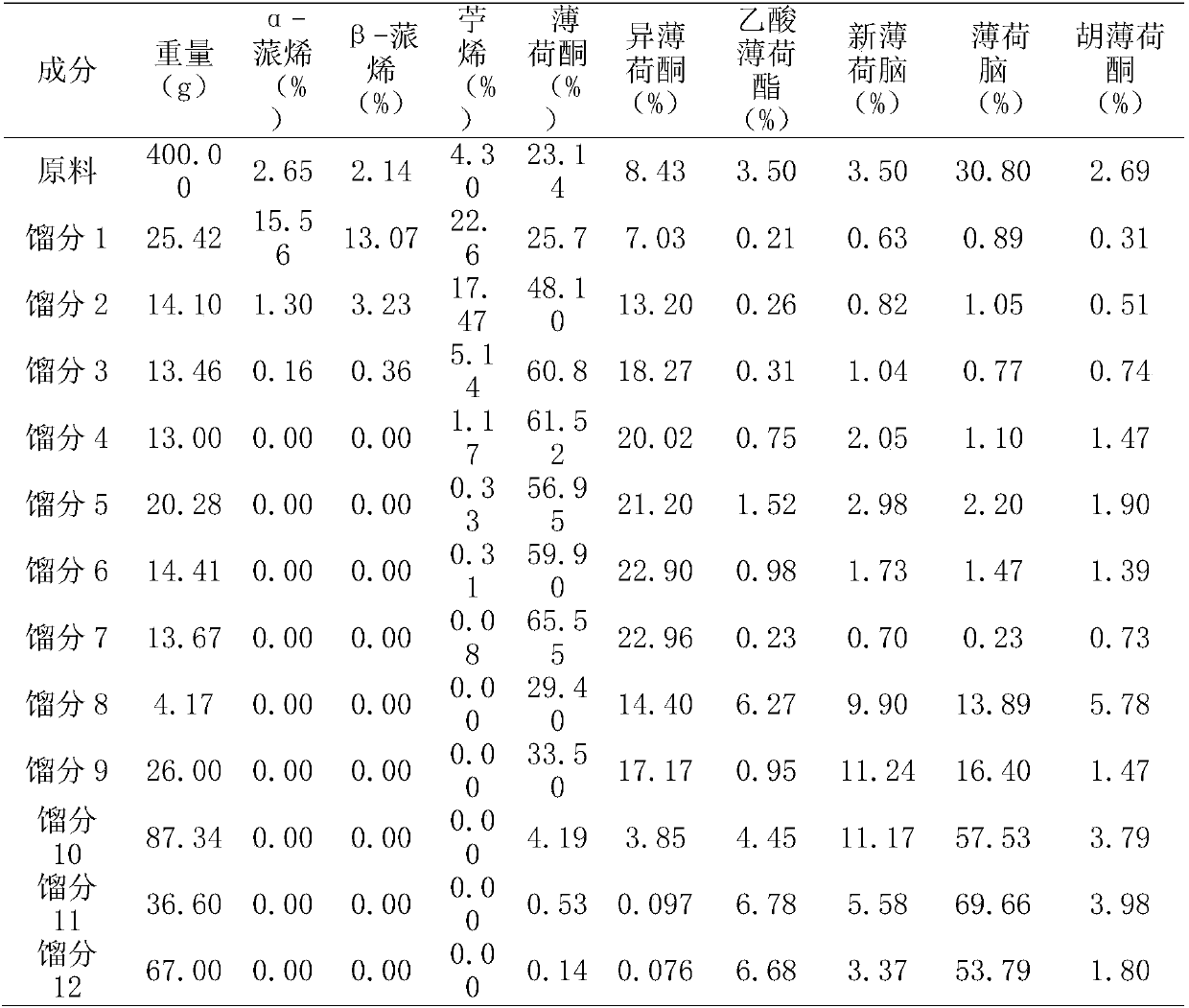

[0022] The content of each fraction separated by azeotropic combined vacuum distillation technology:

[0023]

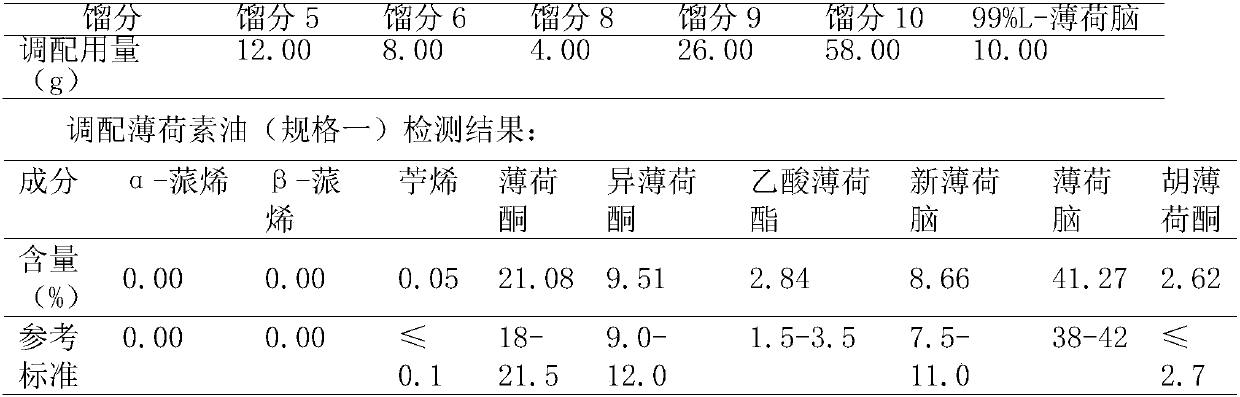

[0024] Deployment of peppermint oil (specification 1) selection amount:

[0025]

[0026] De...

Embodiment 2

[0034] Get 720g of peppermint hair oil, after adding 300g of entrainer water, carry out azeotropic rectification under the condition of packing column height 1.0m, reflux ratio 3:1, and vacuum degree of -0.08MPa, separate the fraction before separation, detect, when fraction When the content of olefins in the medium is ≤1%, stop. Oil and water are separated, and the oil phase is to be treated. The oil phase of the above-mentioned fraction before removal was obtained by rectification under reduced pressure under the conditions of packing column height 1.0m, reflux ratio 3:1, vacuum degree -0.096MPa, and detection, when the L-menthol content in the fraction was ≥50 %, stop. Add 200 g of water to the oil phase, and steam distillation under normal pressure to obtain the rear fraction.

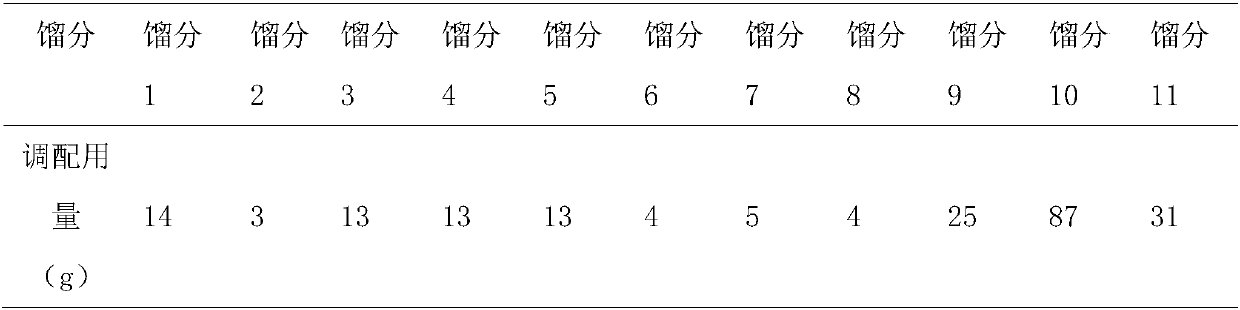

[0035] The content of each fraction separated by azeotropic combined vacuum distillation technology:

[0036]

[0037]

[0038] Deployment of peppermint oil (specification 3) selection amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com