Artificial graphite crucible and preparation method thereof

A technology of artificial graphite and graphite crucible, applied in the field of graphite crucible and its preparation, can solve the problems of poor resistance to rapid cooling and rapid heating, poor service performance, crucible rupture, etc., and achieve the effects of good resistance to strong acid, energy saving, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

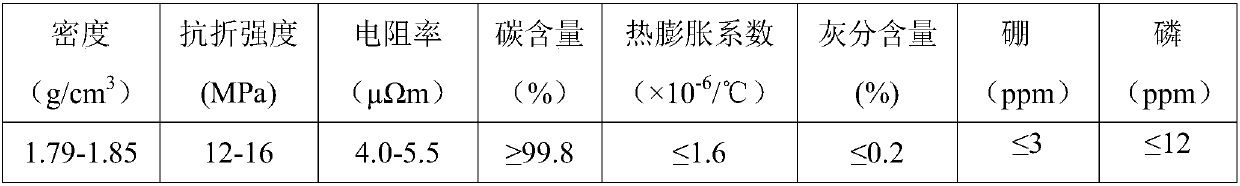

Examples

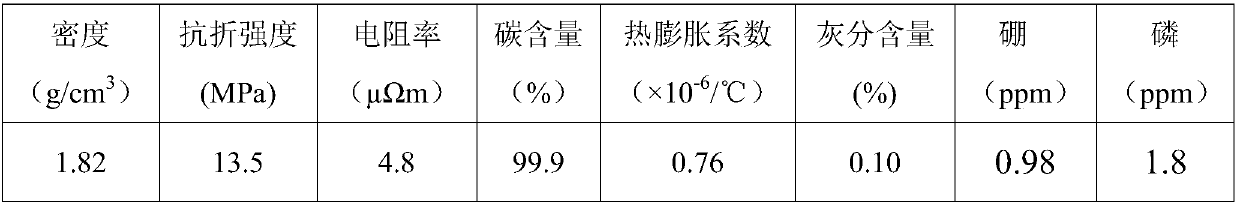

Embodiment 1

[0040] The artificial graphite crucible of the present invention is represented by weight percentage, and the artificial graphite crucible is made of 45% of raw coke, 25% of artificial graphite powder and 30% of high-temperature modified pitch.

Embodiment 2

[0042] The preparation method of the artificial graphite crucible of embodiment 1 of the present invention, the detailed steps of this preparation method are as follows:

[0043]1) Grinding raw coke to 0-6mm, artificial graphite powder to ≤200μm; melting high-temperature modified pitch into liquid;

[0044] 2) The three raw materials processed in step 1) are batched according to the batching ratio of the artificial graphite crucible described in Example 1;

[0045] 3) Send the raw materials prepared in step 2) into a vertical high-speed kneader, and knead evenly at 180-200° C. for 20 minutes to obtain a paste;

[0046] 4) Cool the paste obtained in step 3) to 130-140°C;

[0047] 5) Send the paste obtained after step 4) cooling material into a molding machine, and form it under a pressure of 1200 tons to obtain a graphite crucible raw product. The bulk density of the graphite crucible raw product is 1.78g / cm 3 ;

[0048] 6) Send the graphite crucible raw product obtained in ...

Embodiment 3

[0058] The artificial graphite crucible of the present invention is represented by weight percentage, and the artificial graphite crucible is made of 50% of raw coke, 22% of artificial graphite powder and 28% of refined pitch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com