Insecticide prepared from active ingredients of ginkgo biloba testa and preparation method of insecticide

A technology for ginkgo biloba seed coat and preparation of pesticides, which can be used in pesticides, botanical equipment and methods, acaricides, etc., and can solve the problems of insufficient utilization of material components, high cost of raw materials, and low insecticidal efficiency. , to achieve the effect of being beneficial to the protection of ecological balance, the preparation of products is simple, and the raw materials are environmentally friendly and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

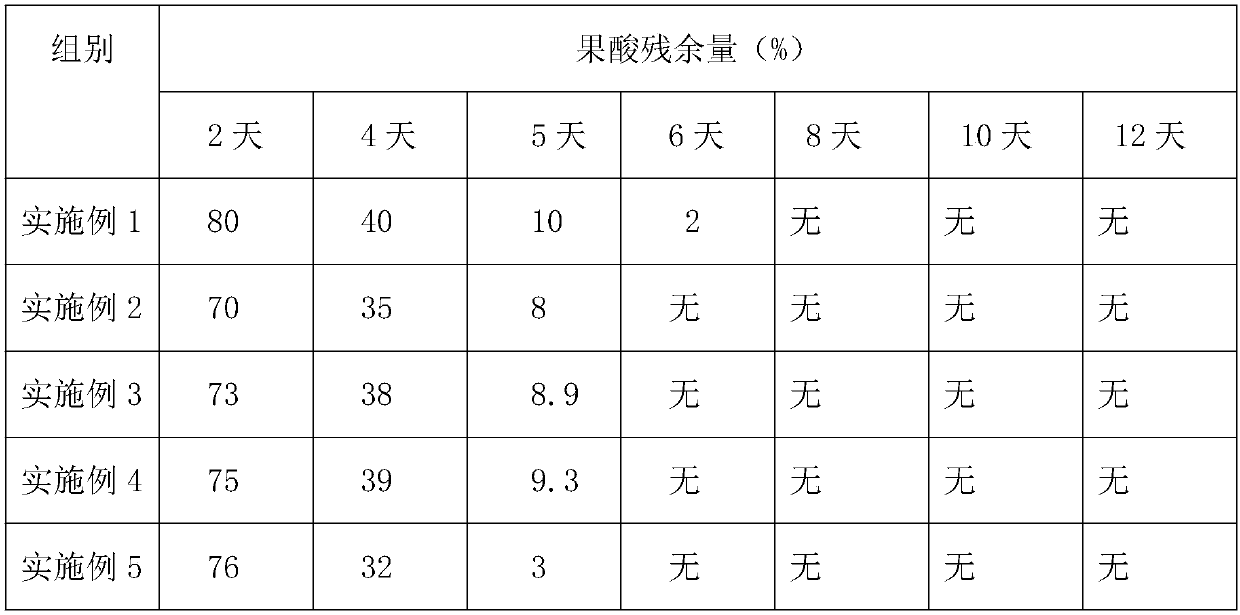

Examples

Embodiment 1

[0039] S1: Ginkgo biloba plant component paste crude extract preparation: take 2 kg of air-dried Ginkgo biloba, put it in a constant temperature blast drying oven at 60°C and dry it until it becomes brittle, and then dry the dried Ginkgo biloba The seed coat is pulverized with a plant pulverizer, and passed through a 30-mesh sieve to obtain dry ginkgo testa powder; then, the prepared ginkgo testa dry powder is leached with 2 times the amount of methanol at room temperature for 35 hours, and filtered to remove impurities. The obtained filtrate was pressurized, concentrated, and evaporated to dryness to obtain 1.6 kg of ginkgo exocarp plant component paste crude extract.

[0040] S2: The obtained ginkgo exocarp plant component paste crude extract is subjected to the following multiple column analysis:

[0041] S201: Dissolve the paste-like crude extract with 50:50 chloroform-methanol, put it on a macroporous resin column, elute with chloroform for 15 seconds, then elute with met...

Embodiment 2

[0046] S1: Ginkgo biloba plant component paste crude extract preparation: take 3 kg of air-dried Ginkgo biloba, put it in a constant temperature blast drying oven at 85°C and dry it until it becomes brittle, and then dry the dried Ginkgo biloba The seed coat is pulverized with a plant pulverizer, and passed through a 40-mesh sieve to obtain dry ginkgo testa powder; then, the prepared ginkgo testa dry powder is leached with 5 times the amount of methanol at room temperature for 48 hours, filtered to remove impurities, The obtained filtrate was pressurized, concentrated, and evaporated to dryness to obtain 2.0 kg of ginkgo exocarp plant component paste crude extract.

[0047] S2: The obtained Ginkgo biloba testa plant component paste crude extract is subjected to multiple column chromatography analysis:

[0048] S201: Dissolve the paste-like crude extract with 50:50 chloroform-methanol, put it on a macroporous resin column, elute with chloroform for 10 seconds, then elute with m...

Embodiment 3

[0053] S1: Ginkgo biloba plant component paste crude extract preparation: Take 4 kg of air-dried Ginkgo biloba, put it in a constant temperature blast drying oven at 80°C and dry it until it becomes brittle, and then dry the dried Ginkgo biloba The seed coat is pulverized with a plant pulverizer, and passed through a 35-mesh sieve to obtain dry ginkgo testa powder; then, the prepared ginkgo testa dry powder is leached with 3 times the amount of methanol at room temperature for 40 hours, filtered to remove impurities, The obtained filtrate was pressurized, concentrated, and evaporated to dryness to obtain 2.6 kg of ginkgo exocarp plant component paste crude extract.

[0054] S2: The obtained Ginkgo biloba testa plant component paste crude extract is subjected to multiple column chromatography analysis:

[0055] S201: Dissolve the paste-like crude extract with 50:50 chloroform-methanol, put it on a macroporous resin column, elute with chloroform for 12 seconds, then elute with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com