Crawler self-propelled dry type water chestnut harvester

A harvester and horseshoe technology, which is applied in the field of crop harvesting, can solve the problems of damage, affecting the screening efficiency, and easily shoveling horseshoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

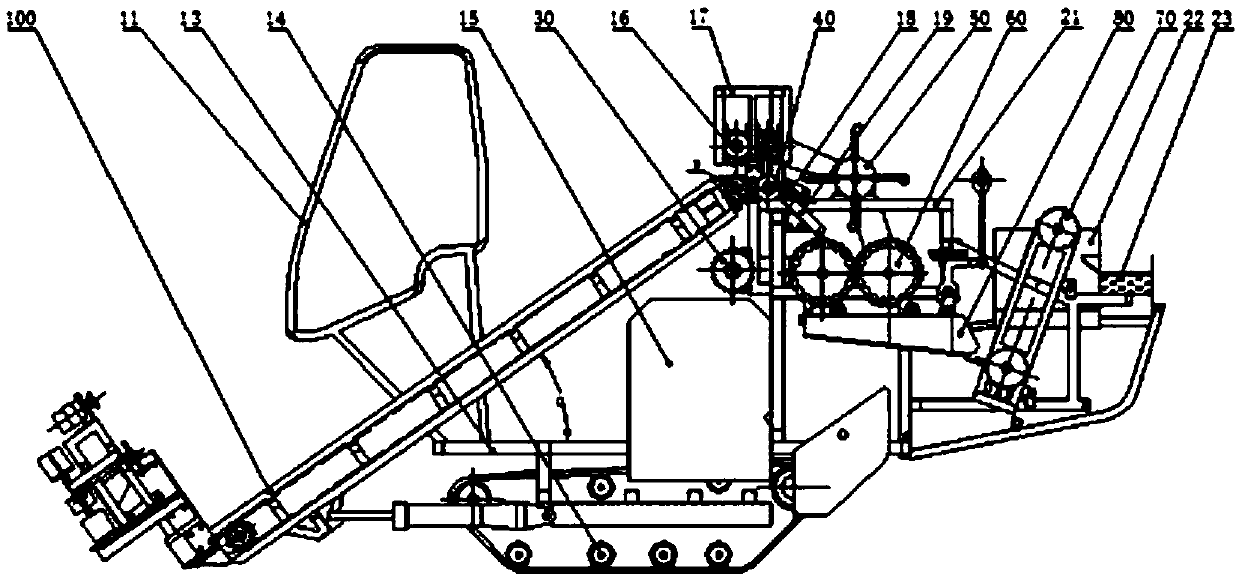

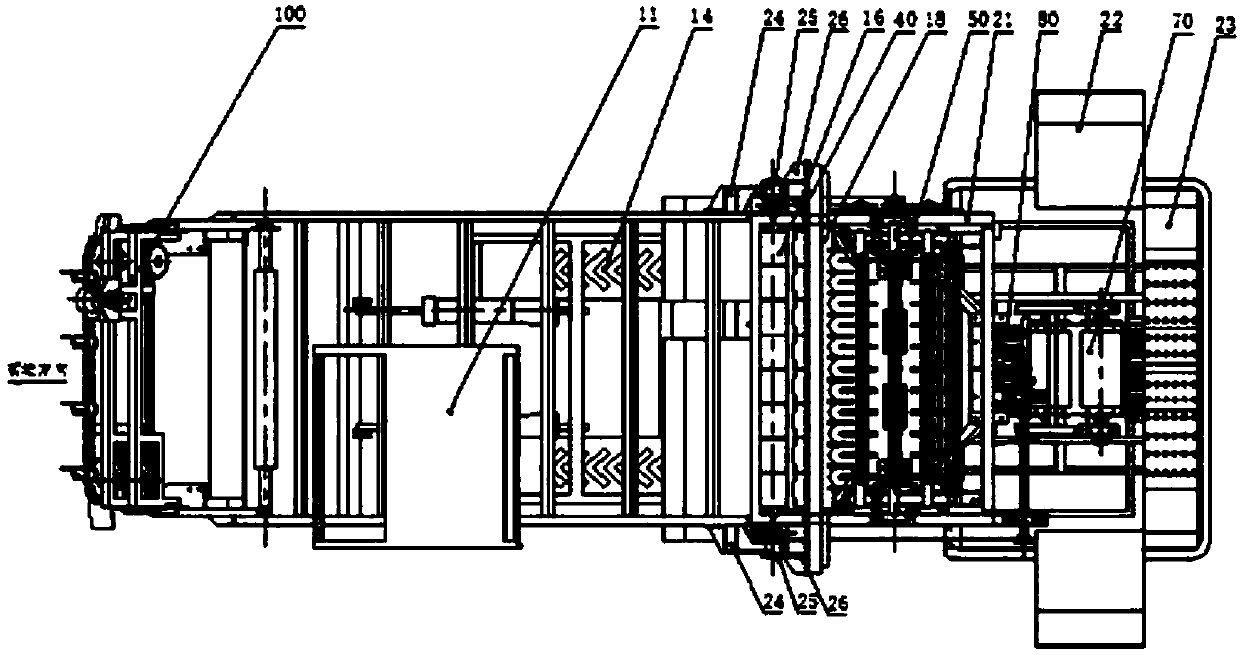

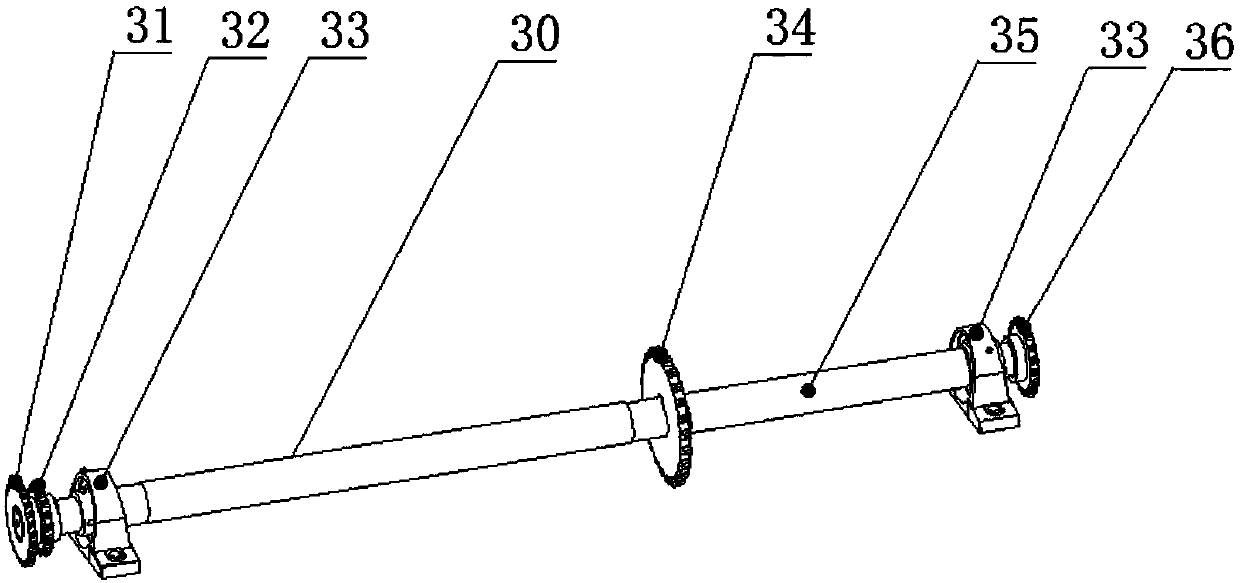

[0046] Present embodiment provides crawler self-propelled dry type horseshoe harvester, as Figure 1-2 , shown in 15, including chassis, reduction box, layered earth taking mechanism, crushing soil part, separation and sorting part, chassis is made of crawler walking chassis (14), chassis engine (15), frame (21), transmission distribution shaft (30), driver's cab (11) and other components, the reduction box (114) is connected with the chassis engine (15), and its effect is to reduce the speed of the chassis engine, and the layered earth-taking mechanism is composed of layered soil-taking mechanism (100 ), hydraulic cylinder (107) and other components to complete the shoveling and side discharge of the surface soil, and the shoveling of the fruit soil layer and transport it to the rear end of the machine for processing; Comb t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com