Micro-nano bubble generator

A technology of micro-nano bubbles and generators, applied in fluid mixers, chemical instruments and methods, aerosol detergent compositions, etc., can solve the problems of unstable system operation, difficult control, large power consumption, etc. The effect of controllable diameter, stable work and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

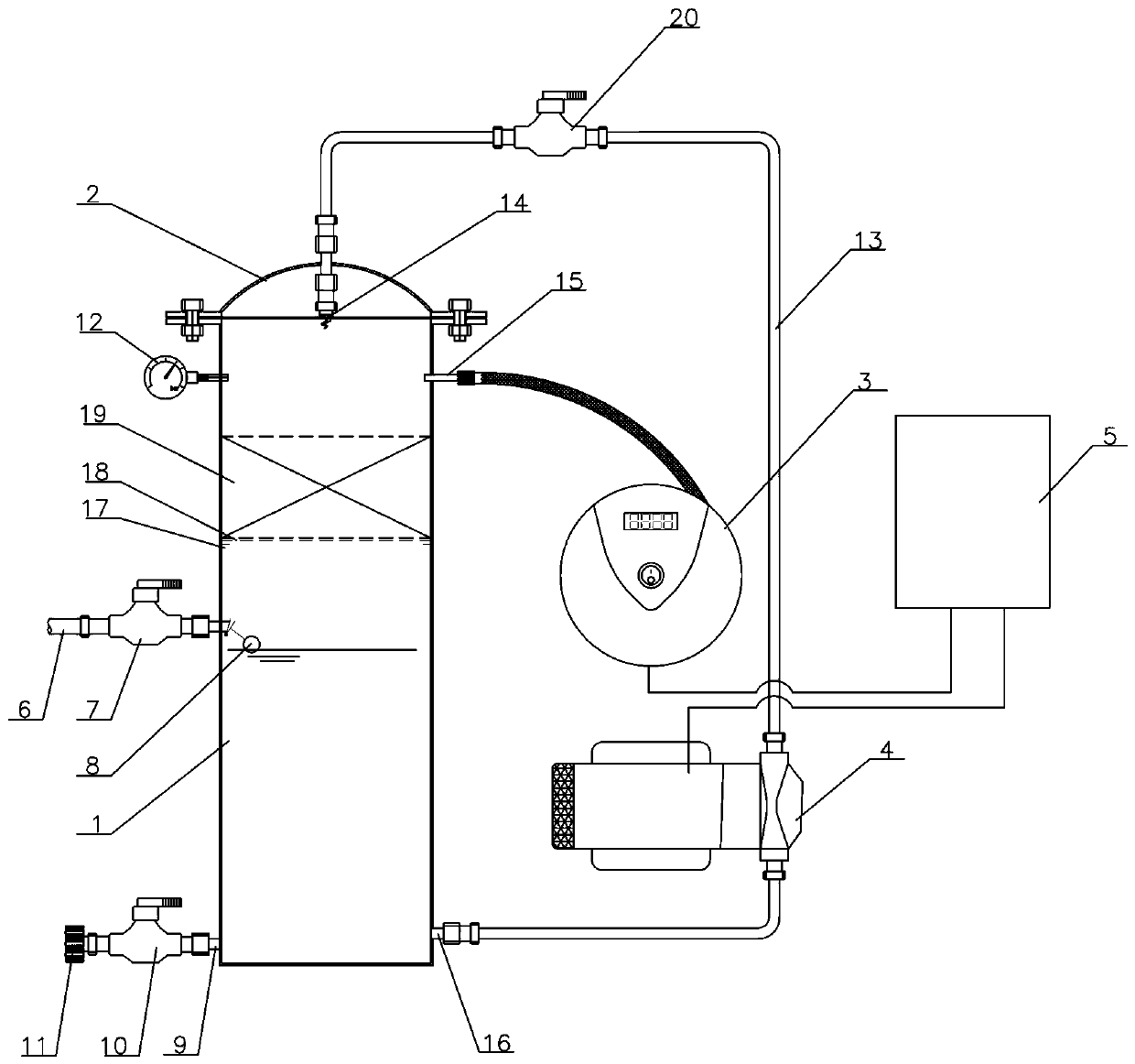

[0012] See attached figure 1 The present invention consists of an air dissolving tank 1, an air pump 3 and a circulating water pump 4. The upper part of the dissolving air tank 1 is an air dissolving area provided with an atomizing water distribution nozzle 14, a valve core 15 and a packing layer 19, and its lower part is A water storage area is provided with a water inlet pipe 6, a float level control valve 8, a micro-nano bubble water outlet 9 and a circulating water outlet 16; the atomizing water distribution nozzle 14 is arranged on the tank cover 2 of the dissolved air tank 1; The packing layer 19 is arranged below the atomizing water distribution nozzle 14 by the support 17 and the orifice plate 18; connection; the float level control valve 8 is arranged in the gas dissolving tank 1, and is connected with the water inlet pipe 6 in the middle of the tank body; 16 is connected to the atomizing water distribution nozzle 14 at the top; the micro-nano bubble water outlet 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com