Modified monomer, modified polymer comprising same, and method for producing the modified monomer and the modified polymer

一种聚合物、改性的技术,应用在含羟基化合物脱水制备醚、醚制备、运输和包装等方向,能够解决效果不足等问题,达到优异加工性、容易改性、耐磨性和抗湿滑性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

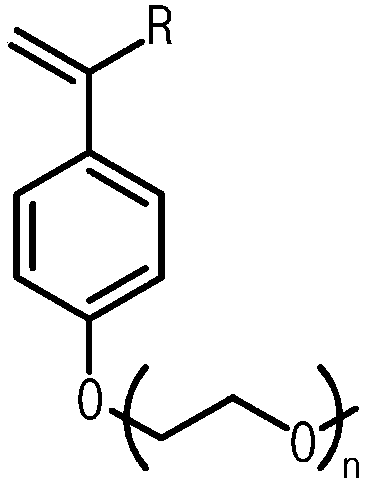

[0039] Preparation Example 1: Preparation of 1-(2-methoxyethoxy)-4-vinylbenzene

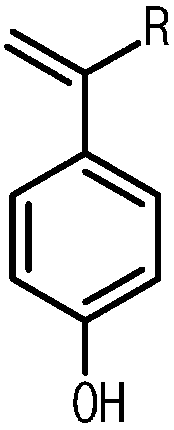

[0040] 1) Preparation of hydroxystyrene

[0041] The sodium hydroxide of 0.275 mole is put into the round bottom flask of 500ml, the dehydrated alcohol of 60ml is added wherein to dissolve sodium hydroxide, then the acetoxystyrene of 0.065 mole is added in the flask, under nitrogen atmosphere will obtain The solution was stirred at room temperature for 4 hours. Next, 50 ml of distilled water and 30 ml of ethyl acetate were sequentially added to the resulting mixture to extract an organic layer, and the extraction process of the organic layer was repeated three times. The extracted organic layer was dried over anhydrous magnesium sulfate and filtered to remove any remaining moisture. Thereafter, the solvent was removed under reduced pressure to obtain 7.54 g (yield: 96%) of hydroxystyrene as a yellow solid. Purified hydroxystyrene 1 H nuclear magnetic resonance (NMR) spectral data are as follo...

preparation Embodiment 2

[0047] Preparation Example 2: Preparation of 1-(2-(2-methoxyethoxy)ethoxy)-4-vinylbenzene

[0048] 1) Preparation of hydroxystyrene

[0049] The sodium hydroxide of 0.275 moles is put into the round bottom flask of 500ml, the dehydrated alcohol of 60ml is added wherein to dissolve sodium hydroxide, then the acetoxystyrene of 0.065 moles is added in the flask, under nitrogen atmosphere, make The solution was stirred at room temperature for 4 hours. Next, 50 ml of distilled water and 30 ml of ethyl acetate were sequentially added to the resulting mixture to extract an organic layer, and the organic layer extraction process was repeated three times. The extracted organic layer was dried using anhydrous magnesium sulfate and filtered to remove residual moisture. Thereafter, the solvent was removed under reduced pressure to obtain 7.54 g (yield: 96%) of hydroxystyrene as a yellow solid. Purified hydroxystyrene 1 H NMR spectral data are as follows:

[0050] 1 H-NMR (500MHz, CD...

Embodiment 1

[0055] Embodiment 1: the preparation of modified styrene polymer

[0056] 28.8 millimoles of styrene and 1.4 millimoles of the styrene compound prepared according to Preparation Example 2 were put into a 100 ml Schlenk flask, 30 ml of anhydrous n-hexane was added thereto, and then the temperature inside the flask was raised to 40°C. When the temperature inside the reactor reached 40° C., 0.25 ml (0.63 mmol in hexane) of a 2.5 M n-butyllithium hexane solution was added to the reactor to cause an adiabatic heating reaction. After about 20 minutes, methanol was used to terminate the polymerization reaction to complete the preparation of the modified styrene polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com