A method for analyzing the composition of textiles

A technology for composition analysis and textiles, applied in the analysis of materials, material analysis by optical means, instruments, etc., can solve the problems of organic solvents and acid-base reagent pollution, etc., and achieve the effect of accurate cross-sectional area and small error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

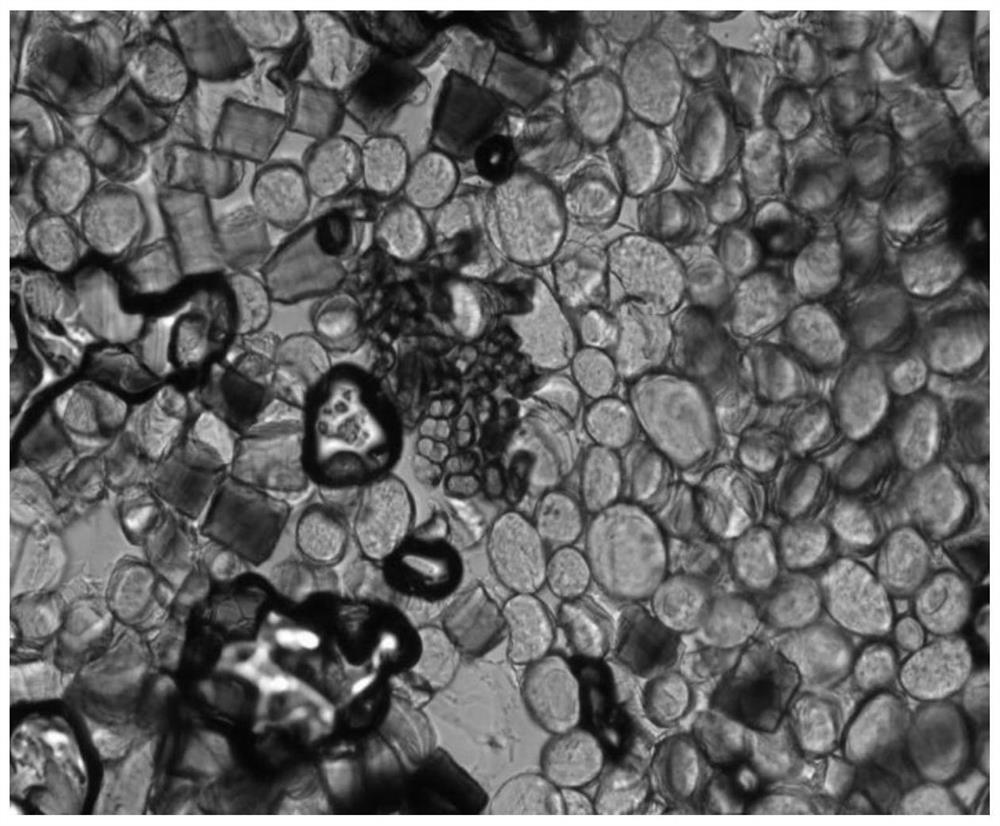

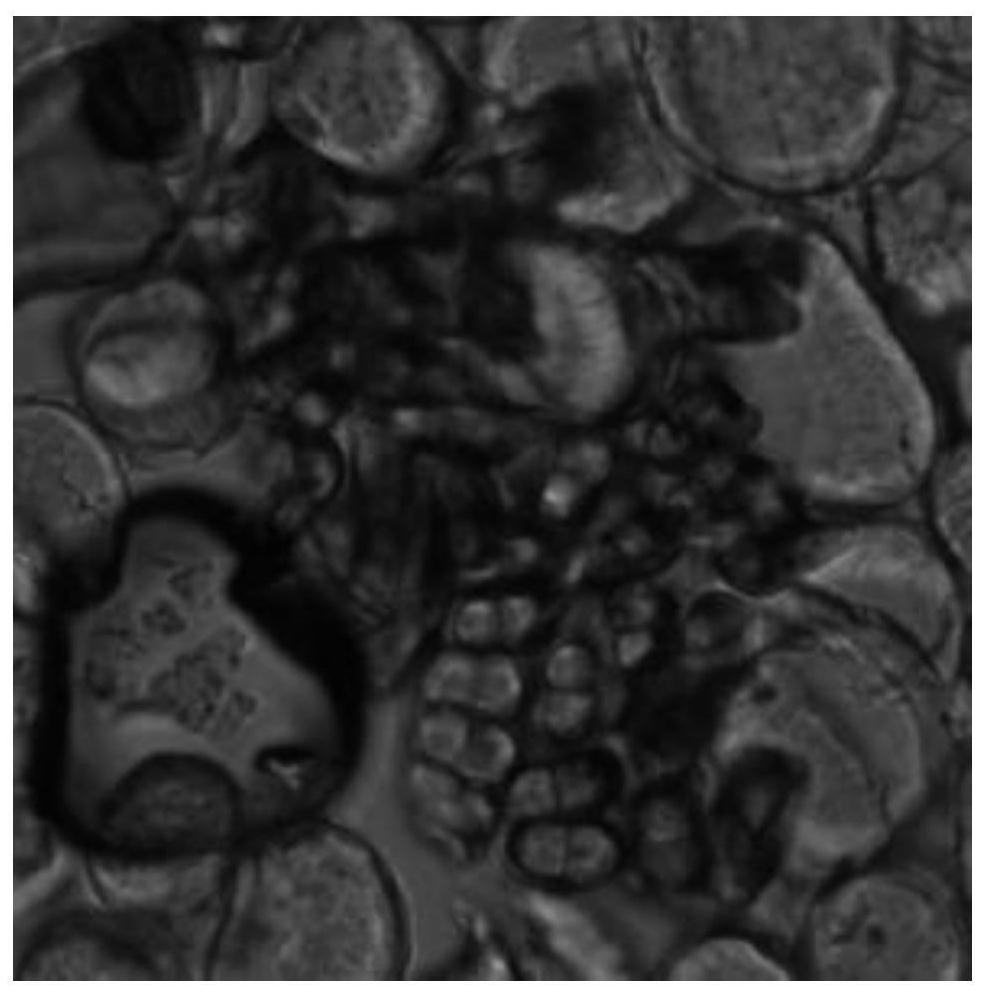

Image

Examples

specific Embodiment approach 1

[0039] Specific implementation mode one: a kind of textile component analysis method of this implementation mode, carry out according to the following steps:

[0040] 1. Cut the mixed fiber bundles into mixed short fibers with a length of 1mm-20mm, uniformly disperse the mixed short fibers, then perform electrostatic induction treatment, and then pass electrostatic regular sorting treatment, fix the mixed short fibers evenly and vertically on the bottom of the container, and arrange them The density is 100-1500 pieces / mm 2 ;

[0041] 2. Pour the embedding reaction solution into the container, and then irradiate it with LED cold light source ultraviolet light. The irradiation time is 5-30 minutes to obtain the embedded mixed short fiber; the adding speed of the embedding reaction solution is 2- 6ml / min, the intensity of ultraviolet light from the LED cold light source is 3000-80000uW / cm at the center of 38cm 2 ;

[0042] 3. Slice the embedded mixed short fibers with a thickn...

specific Embodiment approach 2

[0065] Embodiment 2: This embodiment is different from Embodiment 1 in that: the mixed fiber bundle is cut into short mixed fibers with a length of 5mm-10mm. Others are the same as Embodiment 1.

specific Embodiment approach 3

[0066] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, uniformly disperse and mix short fibers, as electrostatic induction refers to uniformly disperse and mix short fibers in a dispersant aqueous solution, and then add an electrostatic inducer Induction for 5-20 minutes, wherein the mass concentration of the dispersant aqueous solution is 3%, the dispersant is IW, and the electrostatic inducer is a mixture of antistatic agent SN, aluminum potassium sulfate, sodium silicate and glacial acetic acid: the electrostatic inducer in the dispersant aqueous solution The mass final concentration is: antistatic agent SN 5%, aluminum potassium sulfate 5%, sodium silicate 1%, glacial acetic acid 1%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com