A method for detecting the blending ratio of hot-melt fiber based on the change rate of light transmission

A detection method and technology of light transmittance, applied in the direction of transmittance measurement, etc., can solve the problems such as the inability to quantitatively detect the micro melting point instrument and the difference in melting point, etc., and achieve the effects of easy promotion and application, accurate results, and universal testing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

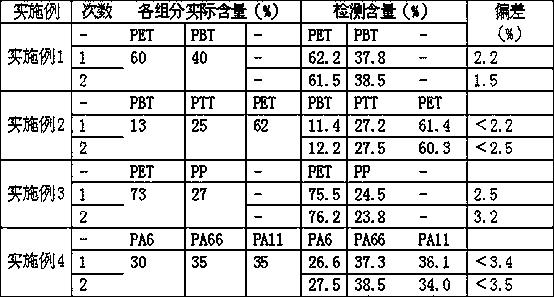

[0036] Example 1 Quantitative analysis of the blending ratio of polyester fiber PBT and PET blended yarn

[0037] The first step, sample preparation, cut the blended yarn sample into mixed fiber fragments with a length of 80um with a Hastelloy slicer, then weighed 10mg of mixed fiber fragments with a ten-thousandth balance, and evenly dispersed them on a piece of cover glass On the slide, cover with a second coverslip, evenly sandwiching the mixed fiber fragments.

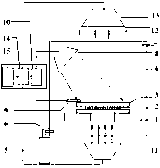

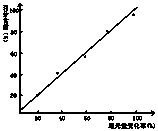

[0038] The second step is to qualitatively detect the types of fibers in the blended samples and their corresponding melting points. Place the coverslip assembly on the detection device (such as figure 1 Shown) on the sample stage 1, make the uniformly dispersed fiber fragments just above the light-transmitting hole with a diameter of 0.8cm, cover the heat preservation cover 4, and pass in nitrogen gas from the air inlet 6 for protection. The temperature rises at a rate of 3°C / min. When the temperature is close t...

Embodiment 2

[0047] Quantitative analysis of embodiment 2 polyester fiber PBT / PTT / PET blended fabric blending ratio

[0048] The first step, sample preparation, cut the blended fabric sample into 60um mixed fiber fragments with a Hastelloy slicer, then weigh 20mg of mixed fiber fragments with a ten-thousandth balance, and disperse them evenly on a cover glass , followed by a second coverslip, sandwiching the mixed fiber fragments evenly in between.

[0049] The second step is to qualitatively detect the types of fibers in the blended samples and their corresponding melting points. Place the cover glass assembly on the sample stage on the detection device, so that the evenly dispersed fiber fragments are just above the light-transmitting hole with a diameter of 1 cm, cover the heat preservation cover, and pass nitrogen gas into the air inlet for protection. Raise the temperature at a rate of 2-3°C / min. When the temperature is close to 223°C, the light transmittance increases significantly...

Embodiment 3

[0061] Example 3 Quantitative analysis of blending ratio of polyester PET / polypropylene PP blended fabric

[0062] The first step, sample preparation, cut the blended fabric sample into 40um mixed fiber fragments with a Hastelloy slicer, then weigh 30mg of mixed fiber fragments with a ten-thousandth balance, and disperse them evenly on a cover glass , followed by a second coverslip, sandwiching the mixed fiber fragments evenly in between.

[0063]The second step is to qualitatively detect the types of fibers in the blended samples and their corresponding melting points. Place the cover glass assembly on the sample stage of the detection device, so that the evenly dispersed fiber fragments are just above the light-transmitting hole with a diameter of 1.2 cm, cover the heat preservation cover 4, and pass nitrogen gas from the air inlet 6 For protection, heat up at a rate of 2-3°C / min. When the temperature is close to 160°C, the light transmittance increases significantly, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com