QCM (quartz crystal microbalance) chemical sensor and preparation method thereof

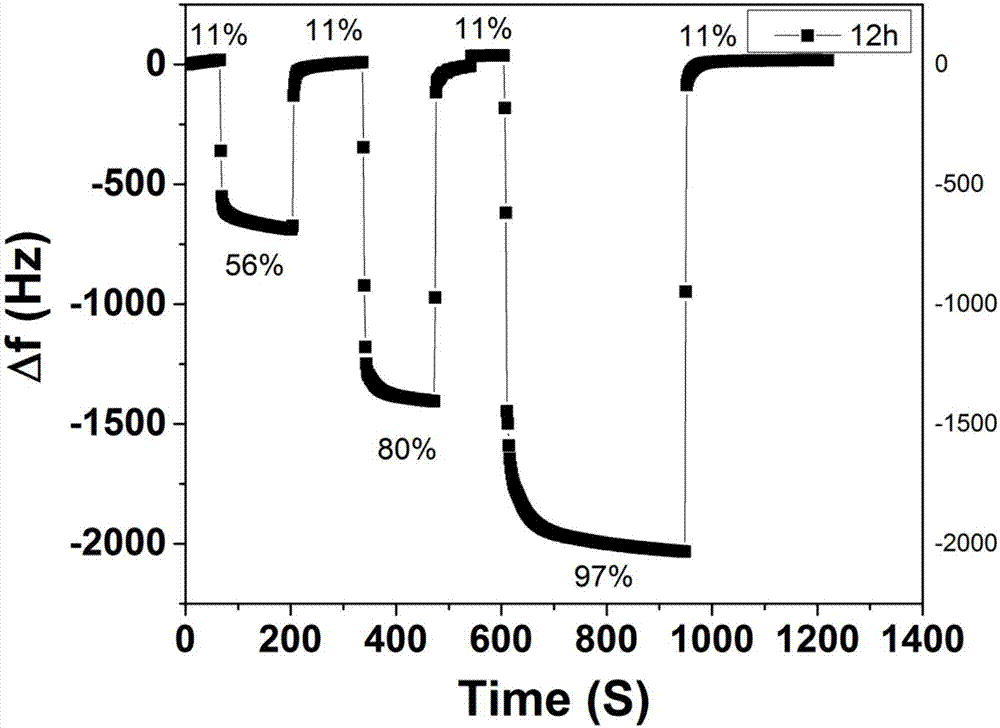

A chemical sensor and sensitive layer technology, applied in the field of sensors, can solve the problems of complex preparation process, slow response and recovery of QCM chemical sensor, etc., and achieve the effect of excellent stability, fast response and recovery characteristics, and high response value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) First, put the quartz crystal oscillating plate into acetone to clean, then into ethanol, and then blow dry with high-pressure nitrogen.

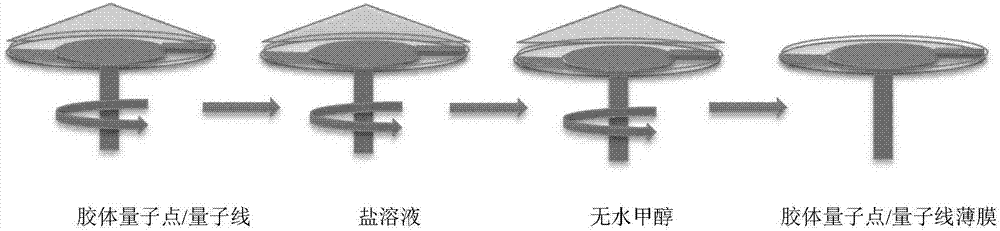

[0030] (2) Then take an appropriate amount of SnO 2 The quantum wire is coated on the quartz crystal oscillating plate to form a uniform film, and then the quartz crystal oscillating plate covered with the quantum dot film is treated with a salt solution to remove the long chain coated on the surface of the quantum dot and modify the film , to facilitate the subsequent recombination of quantum dots and the growth of film thickness; finally, anhydrous methanol solution is used to remove residual short-chain ligands and by-products generated by the reaction of short-chain ligand solutions and colloidal quantum dot solutions.

[0031] (3) Repeat step (2) to obtain a sensitive layer with a desired thickness, and complete the preparation of the chemical sensor.

[0032] The salt solution in the above-mentioned steps (2) is Cu(NO 3 )...

Embodiment 2

[0041] Under nitrogen atmosphere, 0.9g (4mmol) PbO is dissolved in 3ml oleic acid (OA) and 17ml octadecene (ODE) and is heated to 90 ℃ to prepare the precursor of oleic acid lead, as lead source; The temperature of the precursor was raised to 120°C; 180ul (1mmol) TMS was dissolved in 10ml ODE as a sulfur source.

[0042] Inject the sulfur source into the lead source at 120°C. After the color of the reaction system turns black completely (about 15s), put the solution into cold water to quickly lower the temperature to room temperature; add acetone to the cooled solution, and remove it after centrifugal stirring. The supernatant is then dispersed in toluene and centrifuged in acetone for multiple cycles until the supernatant is pure white; the final product obtained is dried into powder and dispersed in n-octane to obtain a 50 mg / ml lead sulfide (PbS) quantum dot solution.

[0043] The specific film-forming steps are the same as in Example 1, but the salt solution used is 10mg / m...

Embodiment 3

[0045] Get 3.3g zinc acetate (Zn(OAc) 2 2H 2 O) Dissolve in 100ml of absolute ethanol, and ultrasonically disperse it at 80°C for 2h, and at the same time, take 0.84g of LiOH·H 2 O was dissolved in 50ml of absolute ethanol and stirred evenly at room temperature. After the zinc acetate solution was cooled to room temperature, the above two solutions were mixed, and stirred at room temperature for 10 minutes to obtain a mixed solution of ZnO quantum dots, then 2ml OA was added to the mixed solution to precipitate the ZnO quantum dots, and the precipitate Add absolute ethanol and n-hexane to wash by centrifugation twice. Finally, the ZnO quantum dots were dispersed in 50ml of n-hexane.

[0046] The specific film-forming steps are the same as in Example 1, but the salt solution used is 10mg / ml zinc chloride (ZnCl 2 ) methanol solution, and anneal the coated quartz crystal at 300°C for 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com