Fluoride red fluorescent powder for blue-ray excited white-light LED and preparation method thereof

A red phosphor, blue light excitation technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problem of no further modified luminescent properties of the product, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

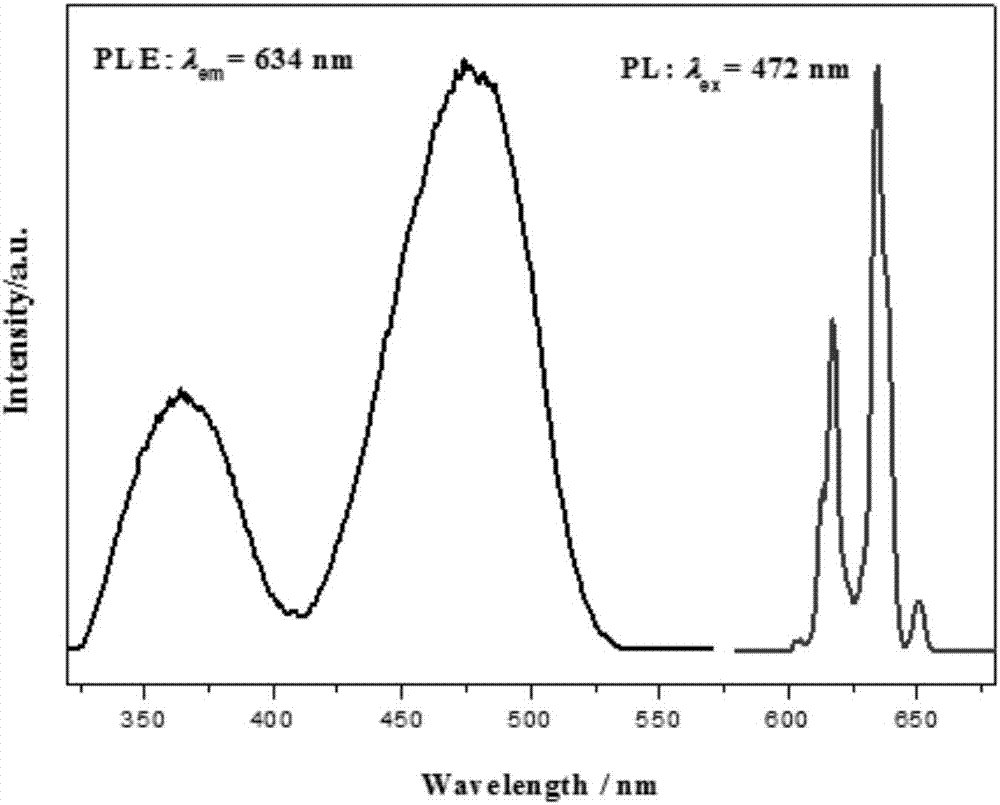

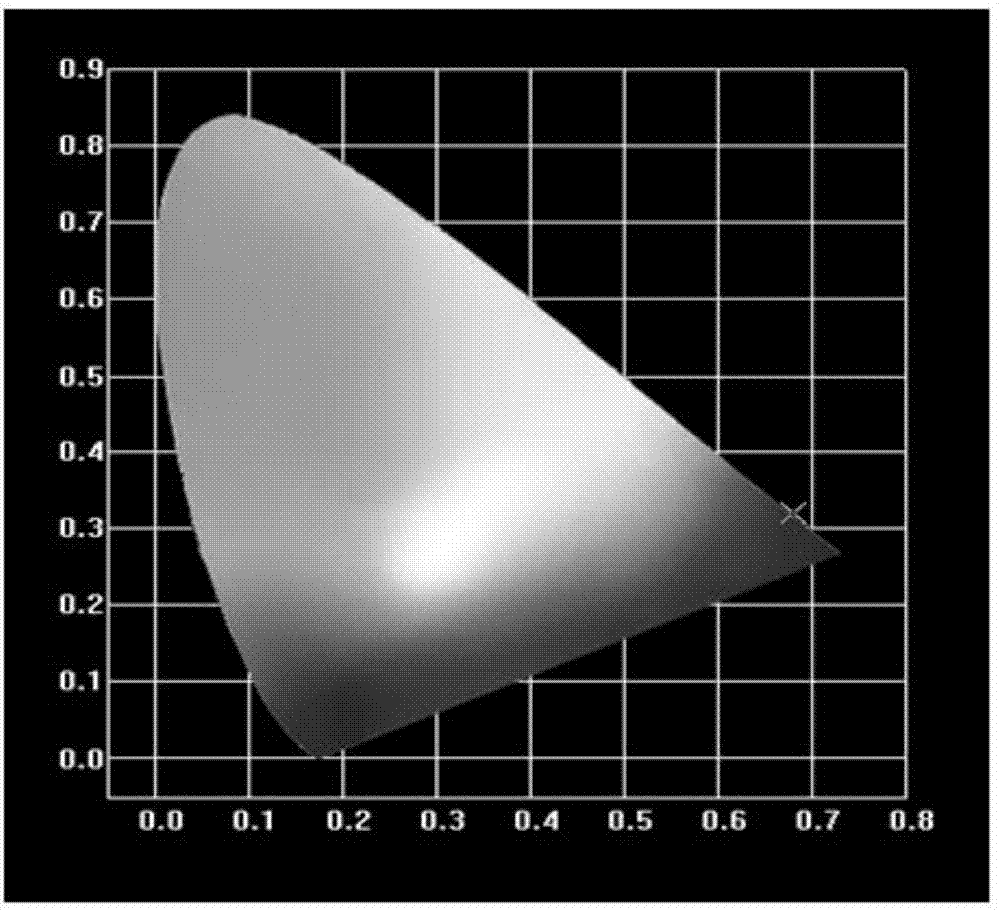

[0032] Embodiment 1. Preparation [K 2 TiF 6 :0.06Mn 4+ ,0.02NaF]

[0033] Take 12.0 mL HF solution (mass concentration 40%) (V HF / W K2TiF6 = 1.0 mL / g ), 6.00g KF 2H2 O (W KF / W K2TiF6 = 0.5), 0.7414 g (3 mmol) K 2 MnF 6 The powder was placed in a 50 mL plastic beaker, and stirred with a magnetic stirrer at room temperature and pressure until the solid raw materials were completely dissolved to obtain a golden yellow transparent solution. Then 12.00 g (50.0 mmol) K 2 TiF 6 The powder was added to the above solution (K 2 MnF 6 / K 2 TiF 6 molar ratio, x =0.06), stirred and reacted at normal temperature and pressure for 90 min, filtered under reduced pressure, and then added dropwise 1.0 mL of 1 mol / L NaNO to the above reaction mixture under stirring 3 The solution was stirred for 30 min, filtered under reduced pressure, and washed 3 times with a small amount of absolute ethanol. Dry the filter cake at 80 °C for 4 h, grind the dried filter cake into powder, an...

Embodiment 2

[0035] Embodiment 2. preparation [Na 2 TiF 6 :0.03Mn 4+ ,0.01KF]

[0036] Take 9.4 mL HF solution (mass concentration 40%) (V HF / W Na2TiF6 = 0.9 mL / g ), 2.08g NaF (W NaF / W Na2TiF6 = 0.2), 0.3707 g (1.5 mmol) K 2 MnF 6 The powder was placed in a 50 mL plastic beaker, and stirred with a magnetic stirrer at room temperature and pressure until the solid raw materials were completely dissolved to obtain a golden yellow transparent solution. Then 10.40 g (50.0 mmol) Na 2 TiF 6 The powder was added to the above solution (K 2 MnF 6 / Na 2 TiF 6 molar ratio, x =0.03), stirred and reacted at normal temperature and pressure for 80 min, filtered under reduced pressure, and then added dropwise 0.5 mL of 1mol / L KNO 3 The solution was stirred for 50 min, filtered under reduced pressure, and washed 3 times with a small amount of absolute ethanol. The filter cake was dried at 80 °C for 6 h, and the dried filter cake was ground into powder, and the obtained orange powder w...

Embodiment 3

[0038] Embodiment 3. preparation [K 2 SiF 6 :0.04Mn 4+ ,0.01NaF]

[0039] Take 7.7 mL HF solution (mass concentration 40%), 4.40g KF·2H 2 O, 0.4942 g (2 mmol) K 2 MnF 6 The powder was placed in a 50 mL plastic beaker, and stirred with a magnetic stirrer at room temperature and pressure until the solid raw materials were completely dissolved to obtain a golden yellow transparent solution. Then 11.01 g (50.0 mmol) K 2 SiF 6 The powder was added to the above solution (K 2 MnF 6 / K 2 SiF 6 molar ratio, x =0.04), stirred and reacted at normal temperature and pressure for 120 min, filtered under reduced pressure, and then added dropwise 0.50 mL of 1 mol / L NaNO to the above reaction mixture under stirring 3 The solution was stirred for 10 min, filtered under reduced pressure, and washed 3 times with a small amount of absolute ethanol. Dry the filter cake at 80 °C for 3 h, grind the dried filter cake into powder, and the obtained orange powder is the final product K 2 Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com