Compound and lubricating grease with anti-oxidation and thickening functions and their preparation method

A compound and grease technology, which is applied in the field of compound and grease and their preparation, can solve the problem of synergistic effect of anti-oxidant and thickener, achieve excellent high-temperature anti-oxidation performance, controllable preparation process, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

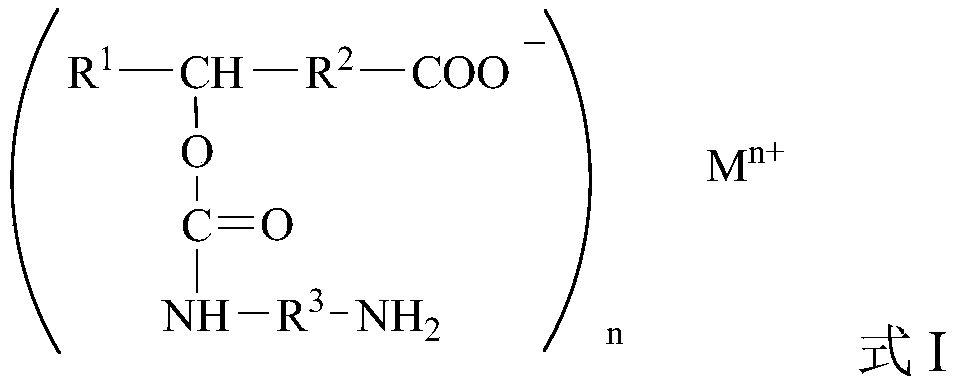

[0040]According to the second aspect of the present invention, various conventional methods can be used to obtain the metal salt of hydroxy fatty acid, for example, it can be obtained by saponifying hydroxy fatty acid with a metal source. According to a preferred embodiment, the preparation method of the metal salt of hydroxy fatty acid comprises: The hydroxy fatty acid and the metal source are mixed for saponification reaction, and then the product obtained by the saponification reaction is selectively heated and dehydrated, and the metal source is a metal oxide, a metal hydroxide and a metal alkoxy compound (such as formazan Oxygenated compounds, ethoxylated compounds, etc.) (with the help of water as a solvent). The general formula of the alkoxy compound can be M n+ (OR - ) n (such as Zr 4+ (OR - ) 4 、Na + (OR) - , Li + (OR) - or Ca 2+ (OR - ) 2 etc.), wherein, R can be C1-C10 alkyl, preferably C2-C6 alkyl, such as methyl, ethyl, n-propyl, n-butyl, tert-butyl,...

Embodiment 1

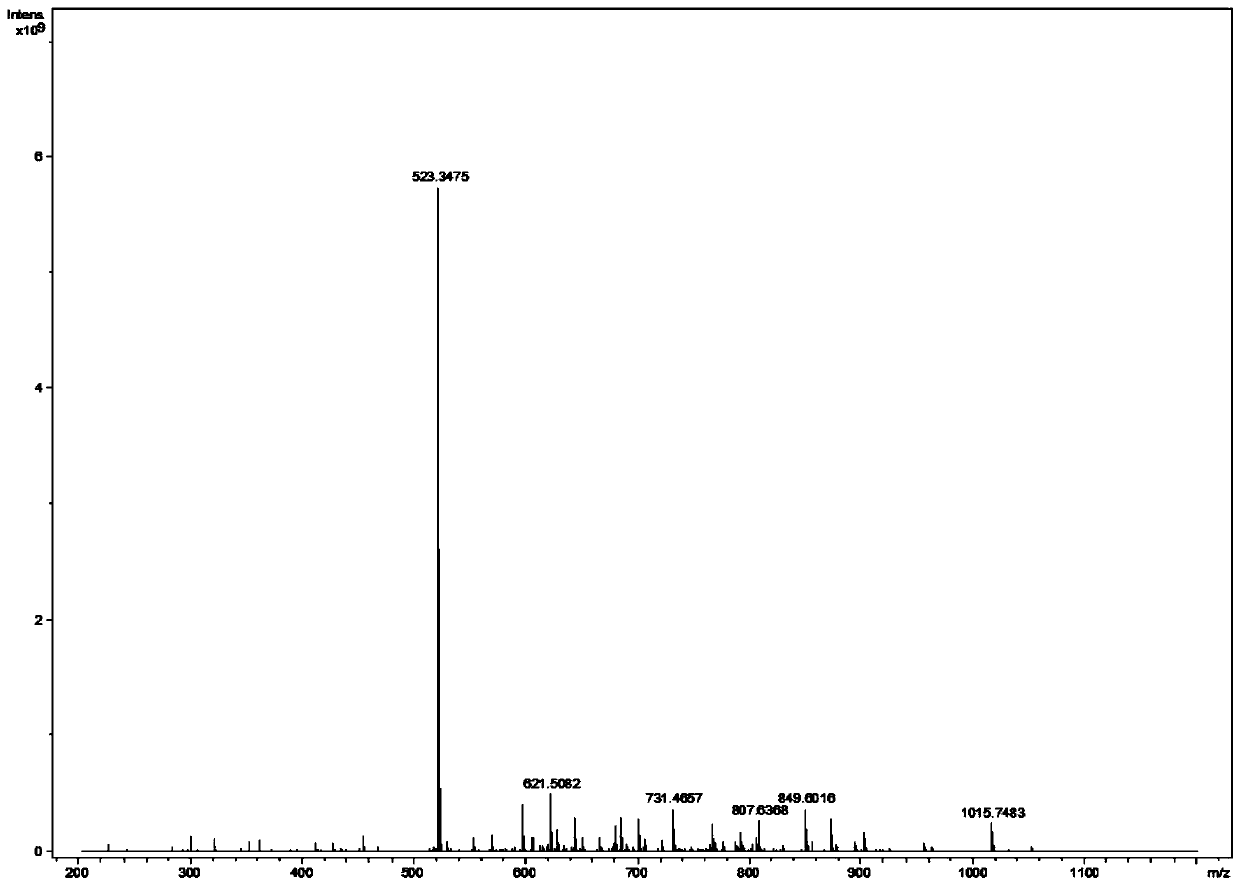

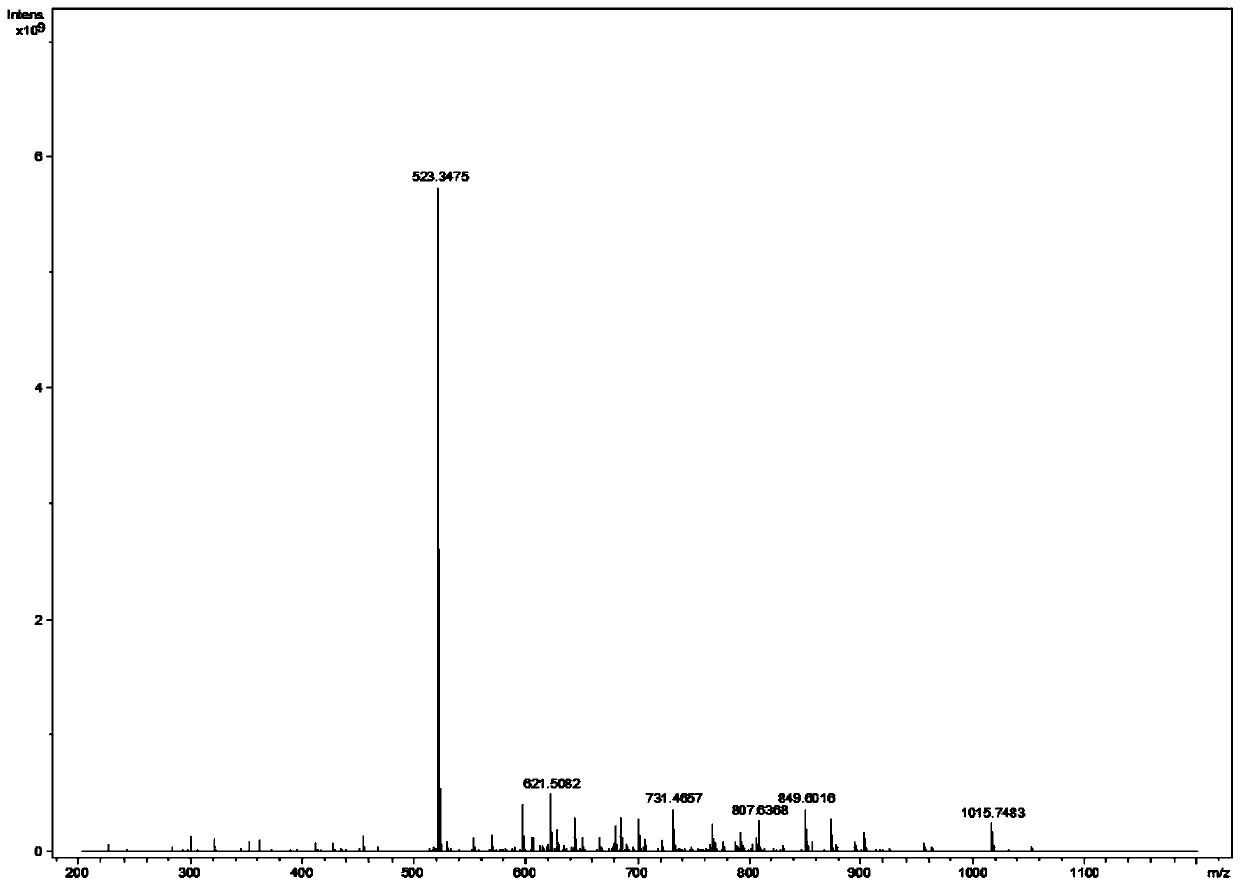

[0080] (a) Preparation of antioxidant additive: Add 100kg of 150SN (100°C kinematic viscosity is 5.6mm 2 / s, purchased from Sinopec Yanshan Petrochemical Company, the same below), 10kg of 12-hydroxystearic acid, stirred, and became a homogeneous system after being heated up to 80°C. At this time, 1.4kg of lithium hydroxide monohydrate and 5kg of water Add it slowly, heat up to 105°C for saponification for 2 hours, then heat up to 115°C, add 8.33kg of diphenylmethane diisocyanate (MDI) and 1kg of catalyst (tripropylamine), react for 30min, add 1kg of water, and react for 30min, Raise the temperature to 210°C, keep the temperature constant for 10 minutes, add 30kg of 500SN base oil, stir to lower the temperature, homogenize, filter, and degas, take out the kettle to obtain the oil-containing additive, wash and filter with petroleum ether several times, and the product obtained after drying is an antioxidant additive. The product is tested using Fourier transform ion cyclotron re...

Embodiment 2

[0085] (a) Preparation of antioxidant additive: Add 100kg of 150SN (100°C kinematic viscosity is 5.8mm 2 / s, purchased from Sinopec Yanshan Petrochemical Company), 10kg of 12-hydroxystearic acid, 6.8kg of azelaic acid, stirred, and after the temperature was raised to 90°C, 4.05kg of sodium hydroxide and 10kg of water were slowly added thereto, Heat up to 105°C for saponification for 3 hours, then heat up to 120°C, add 8.33kg of MDI and 0.1kg of catalyst (potassium carbonate), react for 2h, then add 2kg of ethylenediamine, after reacting for 30min, add 5.8kg of tolyl diisocyanate ( TDI), react for 30 minutes, then add 2kg of water, react for 30 minutes, then raise the temperature to 180°C, keep the temperature for 10 minutes, cool down to 80°C and grind to obtain an oil-containing additive, wash and filter with petroleum ether several times, and the product obtained after drying is an antioxidant additive . This product is tested using Fourier Transform Ion Cyclotron Resonance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com