Waste steel apron conveyor, conveying method and application

A technology of conveyors and scale plates, which is applied in the field of conveying methods and applications, scrap steel scale plate conveyors, can solve the problems of uneven tension force of the traction chain, reduce the service life of equipment, increase the cost of use, etc., and achieve the benefit of conveying , prolong the service life and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

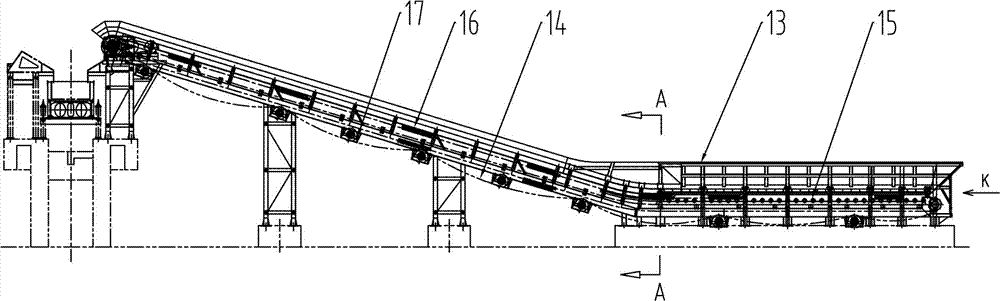

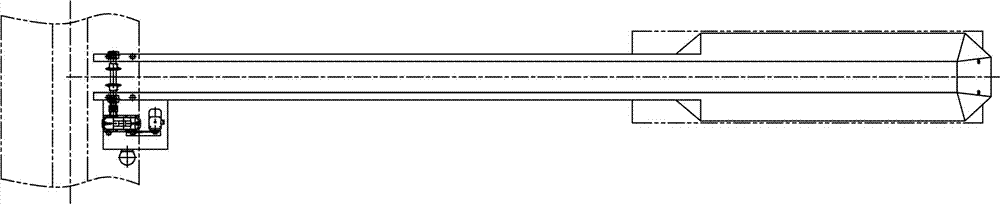

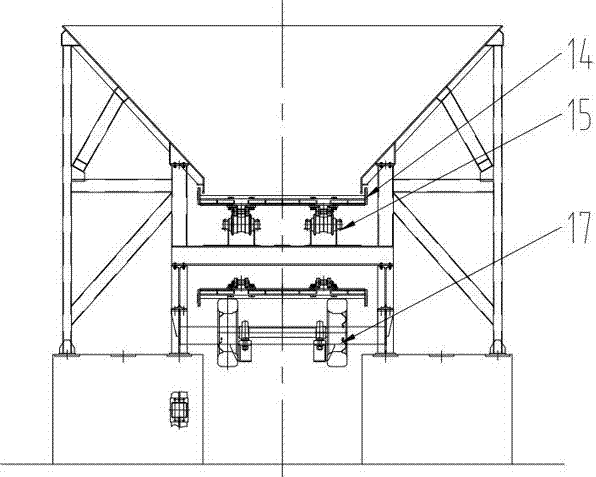

[0037] Such as figure 1 As shown, a scrap steel slab conveyor includes a frame 13, on which a slat group 14 for scrap steel transportation is provided. The slat group 14 is along a horizontal support mechanism 15, an inclined support mechanism 16 and a return support mechanism 17 Cycle movement. The scrap steel slab conveyor is composed of a horizontal section, a curved section and an inclined section.

[0038] Such as Figure 3-4 As shown, the horizontal support mechanism 15 uses equidistant excavator support wheels, the inclined support mechanism 16 uses wear-resistant slide rails, and the return support mechanism 17 uses elastic runners 21 arranged at intervals, and the elastic runners 21 are transported along the return journey. The slat groups 14 are arranged up and down in the length direction. Through the use of excavator rollers at the receiving part, when the magnetic chuck is directly fed, the receiving end can buffer the impact of the feeding, and the bearing capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com