Non-contact intelligent card manufacturing production line

A non-contact smart card and production line technology, applied in coil manufacturing, manufacturing tools, welding equipment, etc., can solve problems such as cumbersome transportation, affecting production efficiency, processing accuracy, and reducing production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

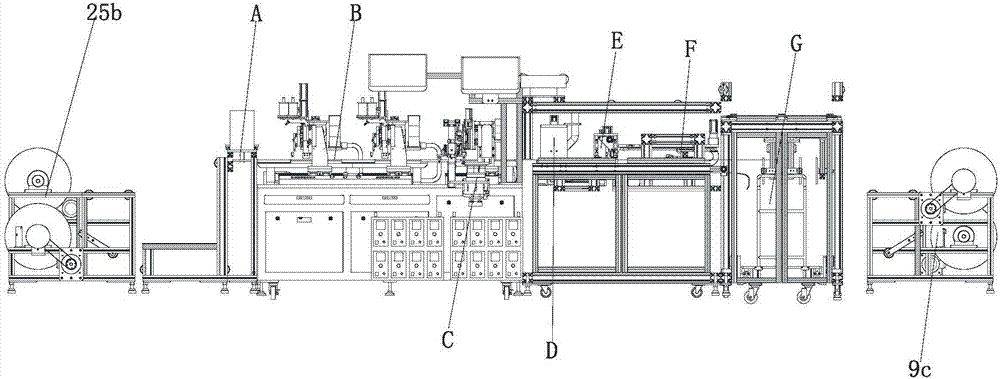

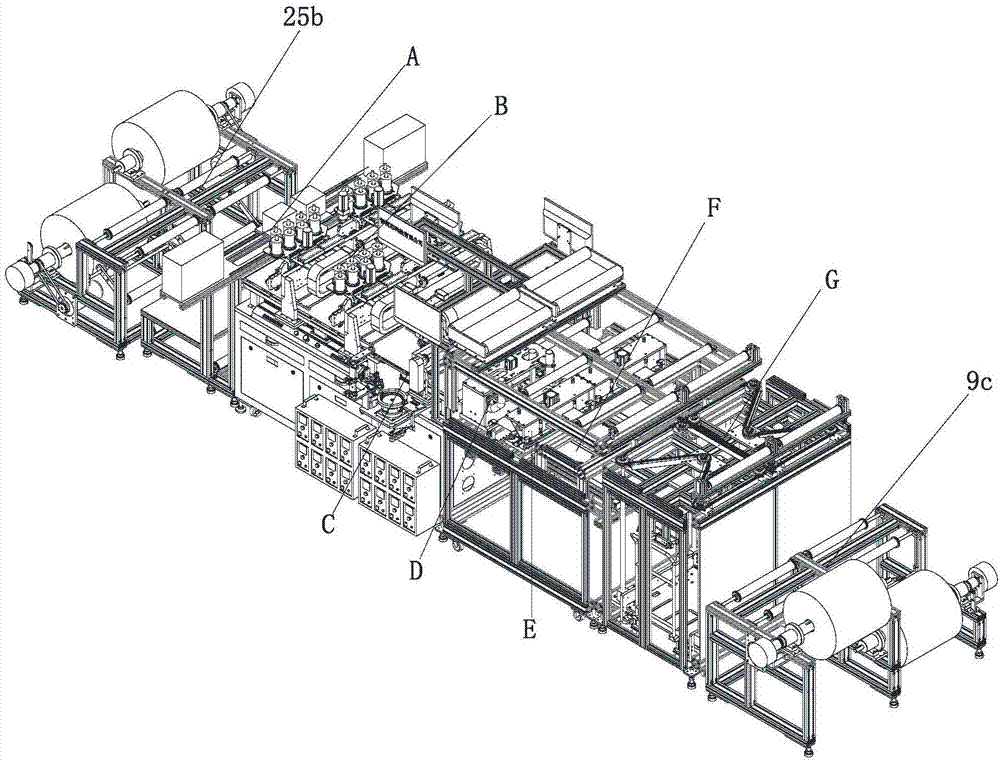

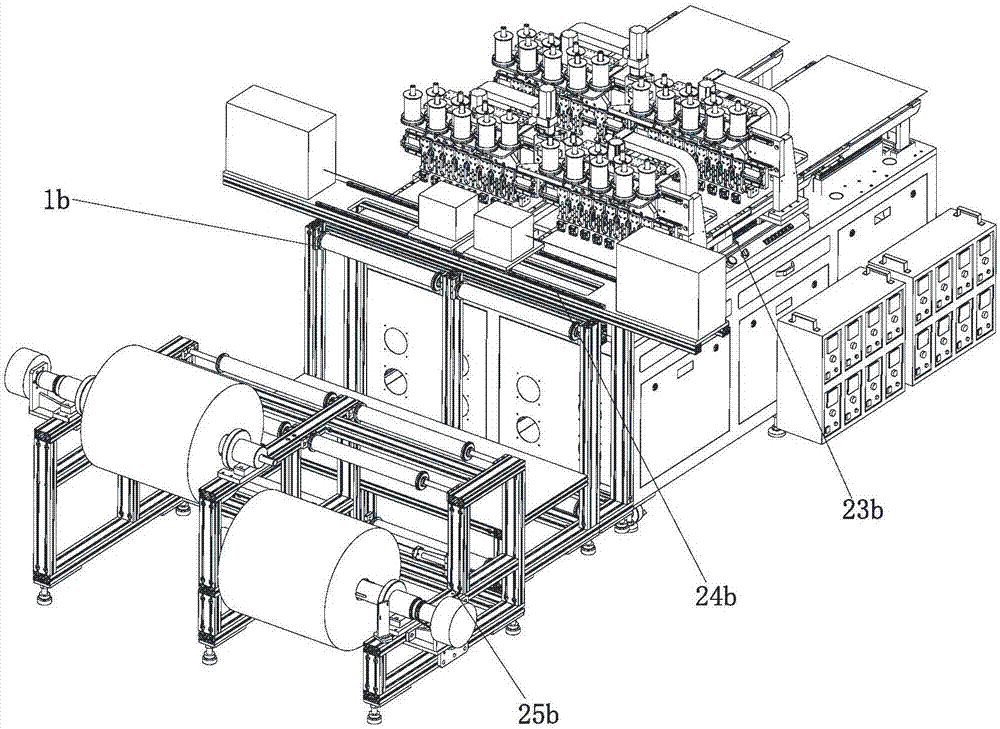

[0112] see Figure 1-Figure 71 , a kind of non-contact smart card manufacturing production line of the present embodiment, comprises frame 1, the PVC sheet material installation frame 25b that is used to install PVC sheet material roll, the sheet material roll installation frame 9c that is used to install PVC cover sheet material roll, carries out Laser drilling module A for laser drilling, smart card winding processing module B for winding PVC sheets, chip welding module C, ultrasonic composite welding module D, for pulling and conveying PVC sheets and PVC covering sheets The traction module F and the collection module G; along the conveying direction of the PVC sheet, the laser drilling module A, the smart card winding processing module B, the chip welding module C, the ultrasonic composite welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com