Fabrication method of flexible sers substrate and its application for specific detection of pat

A specific and flexible technology, applied in measuring devices, material excitation analysis, instruments, etc., can solve the problems of low accuracy or sensitivity, difficult to detect quickly and accurately, and achieve high accuracy, low cost, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

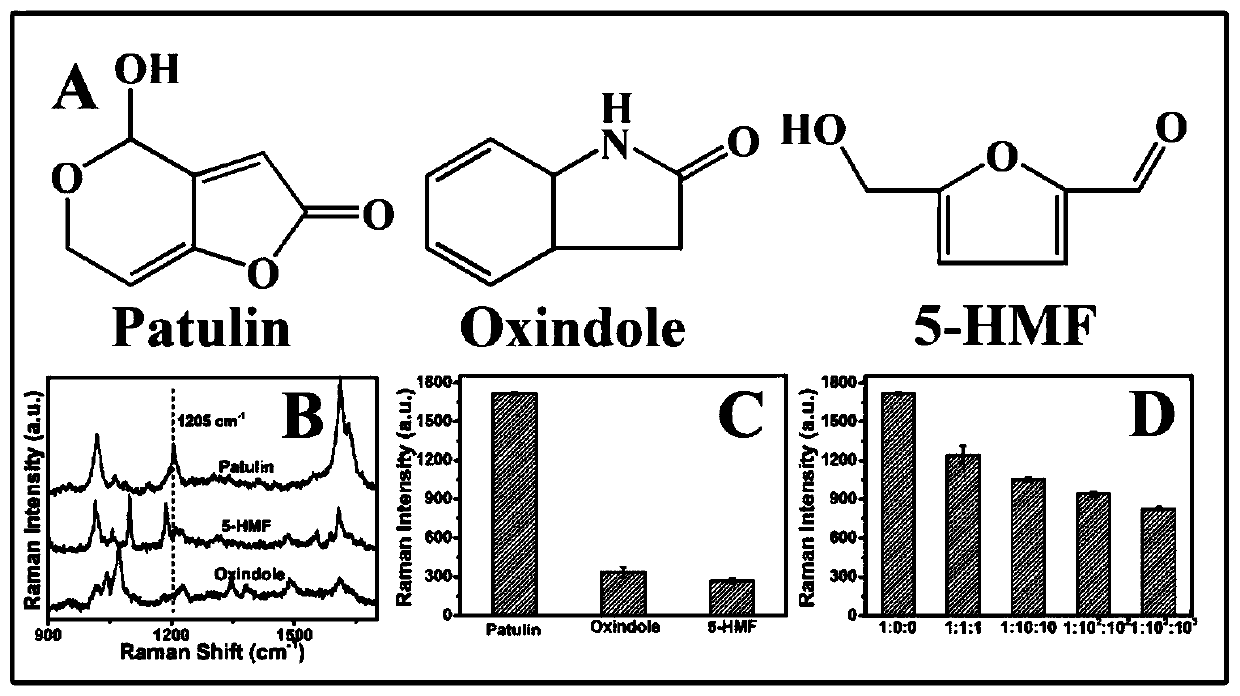

AI Technical Summary

Problems solved by technology

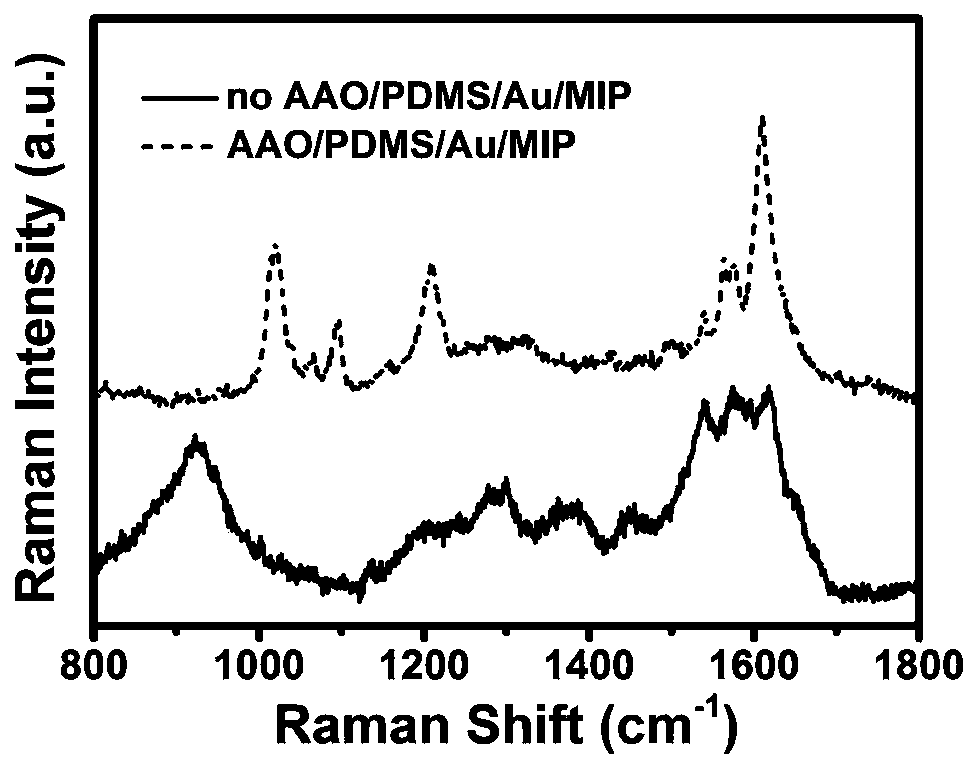

Method used

Image

Examples

preparation example Construction

[0033] An embodiment of the present invention provides a method for preparing a flexible SERS substrate, comprising the following steps:

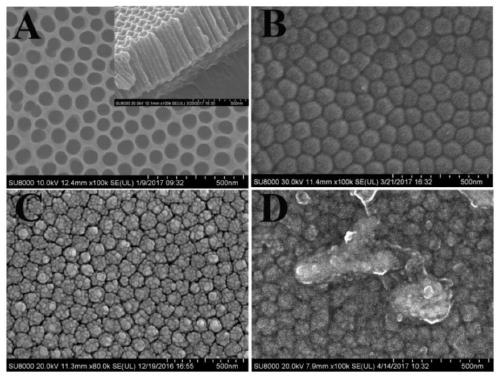

[0034] S1. Anodize aluminum (purity 99.999%) to obtain an AAO (anodized aluminum oxide) template with regular porous structure:

[0035] The aluminum sheet is used as the anode, and the electrolyte with a concentration of 0.1-0.5M is used (the electrolyte can be selected from sulfuric acid, oxalic acid or phosphoric acid). It is oxidized for 2 to 6 hours under the conditions of temperature, and then put into chromic acid with a temperature of 50 to 70 ° C, a concentration of 1 to 3 wt%, and a concentration of 5 to 8% H. 3 PO4 The oxide layer was removed from the mixed solution to obtain a preliminary porous structure template. In this embodiment, 0.1-0.5M oxalic acid solution is used as the electrolyte. In actual operation, the concentration and type of the electrolyte can be selected according to actual needs. The above electrolyte can ef...

Embodiment 1

[0060] S101. Cut the high-purity aluminum sheet into 2×2cm 2 After being fixed on the glass sheet, it was used as the anode, and the oxalic acid solution with the concentration of 0.3M was used as the electrolyte, and the oxidation voltage was 40V, the oxidation current was 15mA, and the temperature was 0 ℃. is 60°C and contains 1.8wt% CrO 3 and a concentration of 6% H 3 PO 4 The oxide layer was removed by soaking in the mixed solution for 30 min, and a preliminary porous structure template was obtained.

[0061] S102, using the preliminary porous structure template as the anode, put into the oxalic acid solution with a concentration of 0.3M, oxidize for 0.5h under the conditions of an oxidation voltage of 40V, an oxidation current of 15mA, and a temperature of 0°C, the temperature is 30°C, and the concentration 5wt% H 3 PO 4 Pore expansion treatment was carried out in the solution for 30 min to obtain porous anodic alumina (AAO).

[0062] S103. Put the AAO into the pl...

Embodiment 2

[0069] S201. Cut the high-purity aluminum sheet into 2×2cm 2 After being fixed on a glass sheet, it was used as the anode, and the oxalic acid solution with a concentration of 0.1M was used as the electrolyte, and the oxidation voltage was 30V, the oxidation current was 20mA, and the temperature was -5 ℃. The temperature is 40°C and the concentration of CrO is 3wt% 3 and a concentration of 6% H 3 PO 4 The oxide layer was removed by soaking in the mixed solution for 10 min to obtain a preliminary porous structure template.

[0070] S202, using the preliminary porous structure template as the anode, put into the oxalic acid solution with a concentration of 0.1M, oxidize for 20min under the conditions that the oxidation voltage is 30V, the oxidation current is 20mA, and the temperature is -5°C, the temperature is 20°C, and the concentration 3wt% H 3 PO 4 Pore expansion treatment was performed in the solution for 10 min to obtain porous anodic alumina (AAO).

[0071] S203,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com