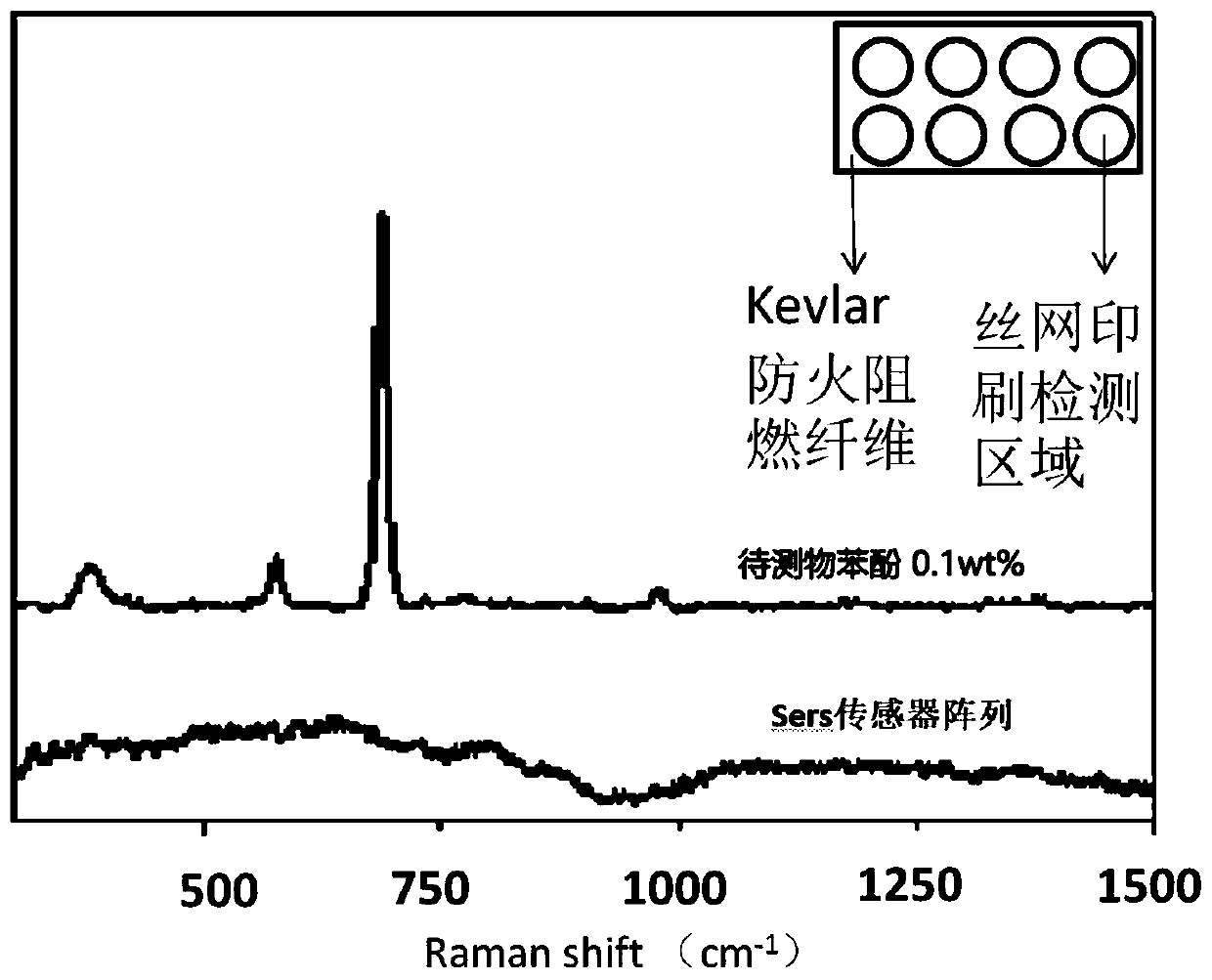

Silk-screen printing SERS sensing array substrate based on fireproof flame-retardant fibers and preparation method and application thereof

A screen printing, fire-retardant and flame-retardant technology is applied to screen-printed SERS sensing array substrates based on fire-resistant and flame-retardant fibers and the fields of their preparation and application, which can solve problems such as inability to meet the requirements, and achieve convenient mass production and Raman spectroscopy. Signal enhancement, easy screen printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation of SERS sensing array of screen printing on the surface of fireproof flame retardant fiber substrate, comprises the following steps:

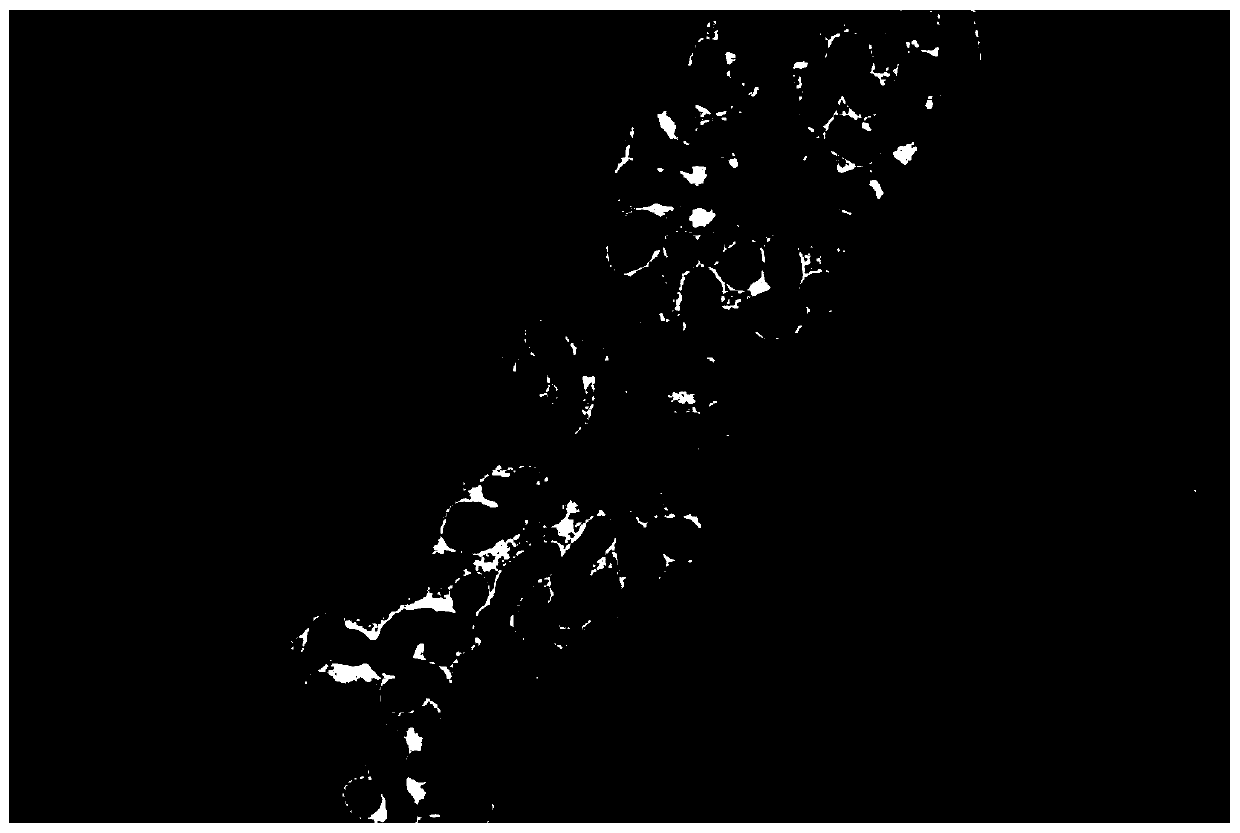

[0048] 1) Firstly, one-pot method is used to synthesize silver colloid in one step. Heat 100mL of 1mmol / L silver nitrate solution to boiling, then mix 2mL of 0.5mg / mL molybdenum disulfide oxide solution with 0.02g of trisodium citrate evenly, and gradually Add it dropwise to the silver nitrate solution, keep the solution in a boiling state for 25 minutes, then stop heating, and after the solution is cooled to room temperature, centrifuge for 20 minutes. After completion, remove 99% of the supernatant and redisperse in 4 mL of deionized water to obtain AgNPs. rMoS at a concentration of 1.3-1.7mmol / L 2 / AgNPs solution. The resulting rMoS 2 / AgNPs nanocomposite transmission electron microscope image figure 1 As shown, it can be seen that the AgNPs attached to the monolayer MoS 2 On the sheet, the particle size dist...

Embodiment 2

[0052] In this example, rMoS 2 The volume ratio of the / AgNPs solution to the binder PAC solution is 2:1, and the rest are the same as in Example 1.

Embodiment 3

[0054] In this example, rMoS 2 The volume ratio of the AgNPs solution to the binder PAC solution is 1:1, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com