Atmospheric corrosion exposure test device and method for metal test samples

A technique for atmospheric corrosion and metal samples, used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

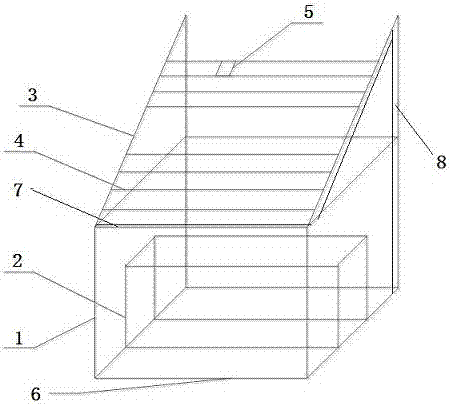

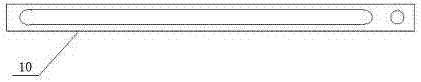

[0039] Install and fix according to the test device, adjust the rotation axis so that the angle between the first inclined beam 10 and the horizontal plane is 15, the height of the base fixing bracket 1 is 10cm, the width is 1m, and the length of the inclined beam is about Four horizontal beams that are parallel to each other and perpendicular to the inclined beam are evenly installed on the inclined beam. The beam is provided with a slot for placing metal samples; the upper two constitute the upper area, and the lower two constitute the lower area.

[0040] Prepare at least 10 pieces of Q235 steel and 10 pieces of galvanized steel metal samples; Q235 steel and galvanized steel are divided into a pair, and the non-working surface is sealed with epoxy resin; 5 pairs of back welding wires As a galvanic corrosion metal sample, the galvanic corrosion metal sample is placed in the lower area; another 5 pairs of samples are placed in the upper area as comparison samples; the spacing bet...

Embodiment 2

[0047] Install and fix according to the test device, adjust the rotation axis so that the angle between the inclined beam and the horizontal plane is 30, the height of the base fixing bracket is 10cm, the width is 1m, and the length of the inclined beam is about The oblique beam is composed of a first oblique beam and a second oblique beam. One end of the waist hole of the second oblique beam is connected to the third hole on the rear vertical beam (the third mounting hole of the rear vertical beam from top to bottom) through a bolt. The other end of the waist hole of the two oblique beams is connected with the first oblique beam installation screw hole through bolts, and the bolts are tightened after the first oblique beam and the second oblique beam are straightened.

[0048] Preparation of Q235 steel, galvanized steel, copper-plated steel, zinc-clad steel, copper, zinc metal samples, Q235 steel and galvanized steel, Q235 steel and copper-plated steel, Q235 steel and zinc-clad s...

Embodiment 3

[0054] Referring to the operation in Embodiment 2, only the angle of the inclined beam and the horizontal plane is changed to 45 and 60 respectively.

[0055] When the angle between the inclined beam and the horizontal plane is 45, the length of the inclined beam is approximately The oblique beam is composed of a first oblique beam and a second oblique beam; at this time, the waist hole at one end of the second oblique beam is connected to the second mounting hole on the rear vertical beam by bolts, and the second oblique beam is connected to the first oblique beam. connection.

[0056] When the angle between the inclined beam and the horizontal plane is 60, the length of the inclined beam is about The oblique beam is composed of the first oblique beam and the second oblique beam; at this time, the waist hole at one end of the second oblique beam is connected to the first mounting hole on the rear vertical beam by bolts, and the second oblique beam is connected to the first obliqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com