Application of manY/levF gene segment to butanol production

A technology of gene fragments and production of butanol, applied in the field of bioengineering, can solve the problems of low utilization rate and restriction of sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

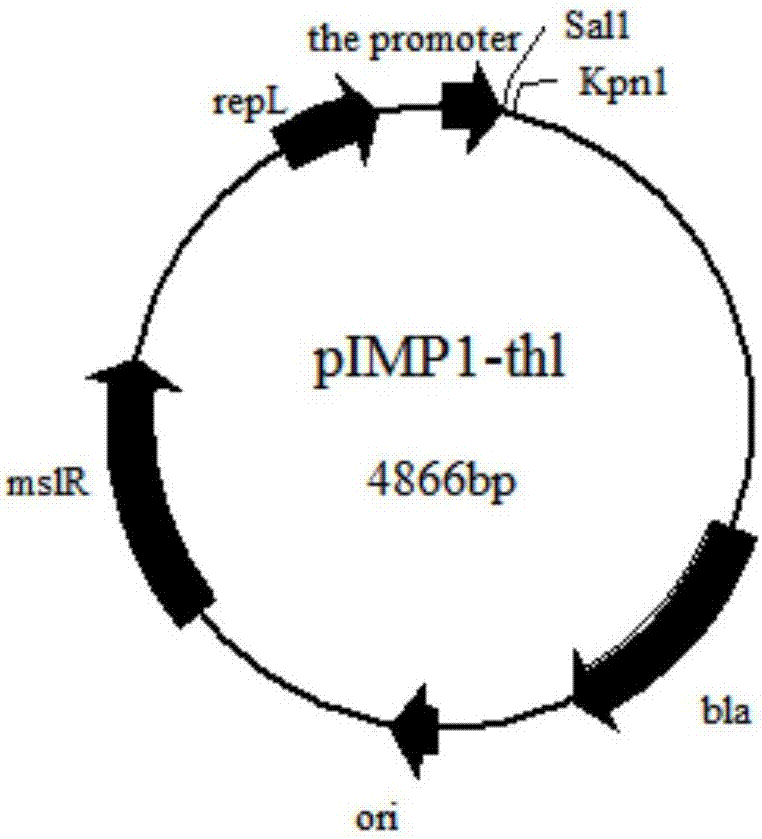

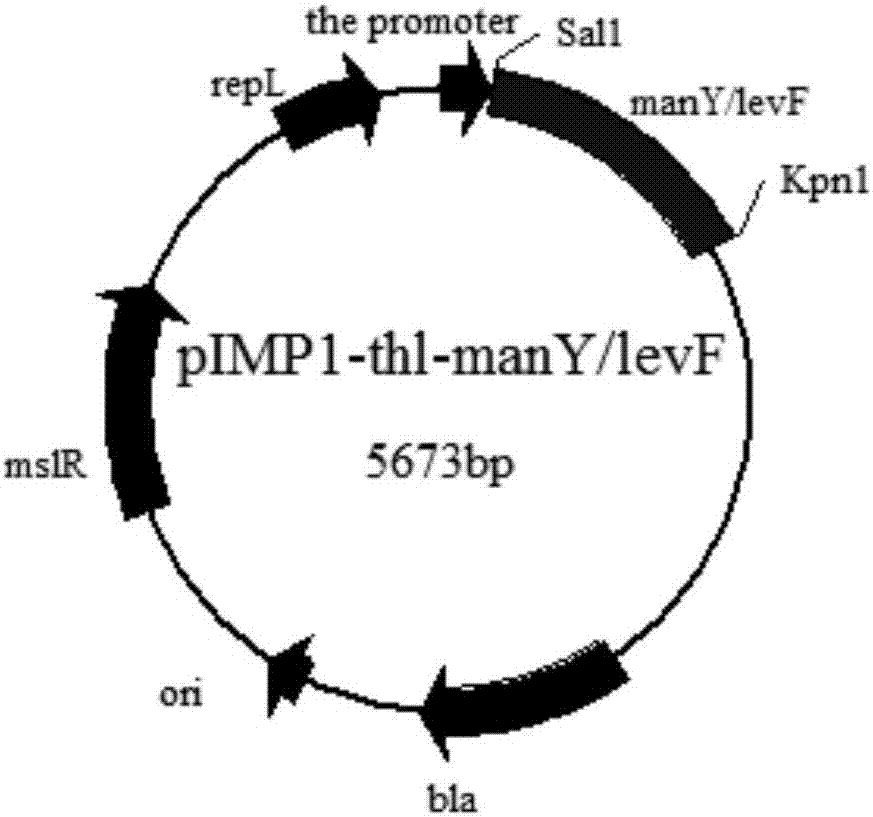

[0039] (1) Construction of manY / levF gene overexpression recombinant plasmid

[0040] Using Sangon Biotech (Shanghai Shenggong) Ezup Column Bacterial Genomic DNA Extraction Kit (Product No.: B518255) to extract Clostridium acetobutylicum C. acetobutylicum ATCC 824 (purchased from American TypeCulture Collection) genomic DNA, using primer: thl -F: GACAC CTGCAG TTTTTAACAAAAATATTGA (the underlined part is the restriction site of Pst I) and thl-R: GACAC GTC GAC TTCTTTCATTCTAACTAACCTC (the underlined part is the Sal I restriction site) amplifies the promoter nucleotide sequence of thiolase from genomic DNA (see SEQ ID NO.3 for the specific sequence), and the thiolase promoter obtained by PCR amplification The DNA fragment was double-digested with Pst I and Sal I, and the pIMP1 plasmid [Mermelstein L.D., Welker N.E., Bennett G.N., Papoutsakis E.T. Expression of cloned homologous fermentative genes in Clostridium acetobutylic...

Embodiment 2

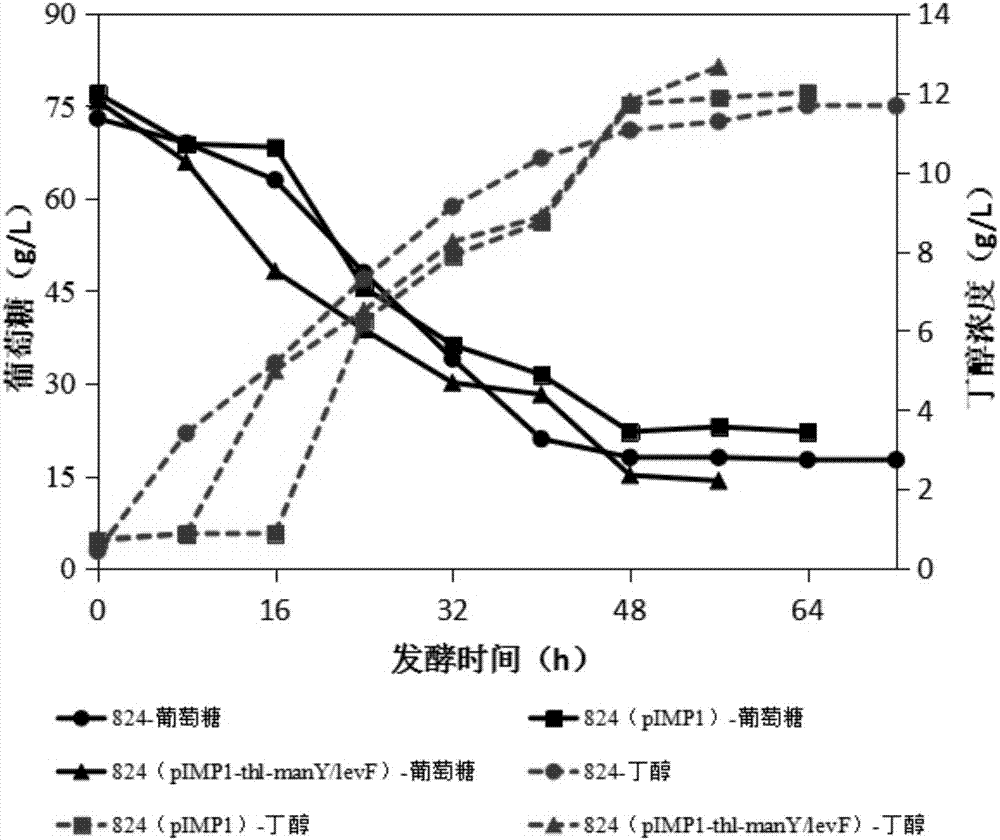

[0045] Butanol is fermented by the recombinant bacterial strain, and the present embodiment comprises the following steps:

[0046] First activate the strains, the recombinant strain Clostridium acetobutylicum ATCC824 (pIMP1-thl-manY / levF) obtained in Example 1 and the empty plasmid strain C.acetobutylicum ATCC 824 (pIMP1-thl) and their starting wild Type strain C.acetobutylicum ATCC 824 were inoculated into the activation medium (containing 50μg / mL erythromycin resistance). In an anaerobic environment, culture statically at 37.5°C for 20 hours, inoculate the activated strains in the seed medium (containing 50 μg / mL erythromycin resistance) according to the inoculum amount of 10% (v / v), and in the shaker For cultivation, the cultivation temperature is 37.5° C., the rotational speed is 150 rpm, and the cultivation is carried out for 24 to 30 hours. Use Biotec-3BG-4 fermenter (Shanghai Baoxing Biological Equipment Engineering Co., Ltd.) for anaerobic fermentation, the amount of...

Embodiment 3

[0059] Overexpression of recombinant strains to produce butanol by fermentation, this embodiment includes the following steps:

[0060] First activate the bacterial species, the overexpressed recombinant strain Clostridium acetobutylicum ATCC824 (pIMP1-thl-manY / levF) obtained in Example 1 and the control empty plasmid bacterial strain C.acetobutylicum ATCC 824 (pIMP1-thl) and The starting wild-type strain C. acetobutylicum ATCC824 was inoculated into the activation medium (containing 50 μg / mL erythromycin resistance). Cultivate statically at 37.5°C for 20 hours in an anaerobic environment, inoculate the activated strains in the seed medium (containing 50 μg / mL erythromycin resistance) according to the inoculum amount of 10% (v / v), and culture in a shaker , the culture temperature is 37.5°C, the rotation speed is 150rpm, and the culture is 24-30h. Use Biotec-3BG-4 fermenter (Shanghai Baoxing Biological Equipment Engineering Co., Ltd.) for anaerobic fermentation, the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com