Powder material for coating high-wear-resistance automobile hub and preparation method thereof

An automobile wheel hub, high wear resistance technology, used in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of cumbersome steps, poor coating effect, cost, etc., and achieve good product performance and good mechanical performance. , the effect of increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

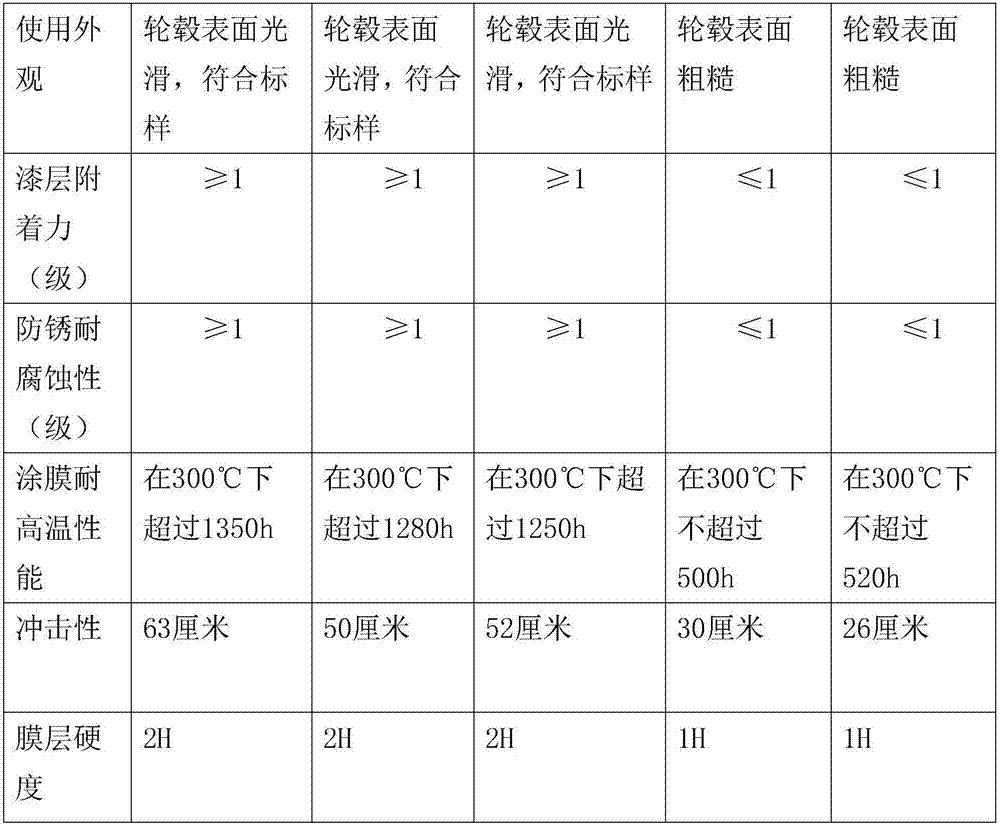

Examples

Embodiment 1

[0086] Embodiment 1: a kind of powder material for coating of high wear resistance automobile wheel hub, its components are calculated by weight percentage: 32.3% of epoxy resin, 30% of modified carboxyl-terminated saturated polyester resin, 0.7% of curing agent, Wear-resistant powder 25%, titanium dioxide 5%, quartz powder 6%, leveling agent 1%.

[0087] The curing agent is hydroxyalkylamide.

[0088] Wear-resistant powder is Al2O3.

[0089] The preparation method of modified carboxyl-terminated saturated polyester resin is:

[0090] 1) Add concentrated sulfuric acid with 1 times its weight and 70% mass fraction to the diatomite powder, filter after stirring, dry the filter residue and calcinate at 500°C for 30min to obtain refined diatomite powder; wherein, the stirring operation is Stir at 1000r / min for 10min, then reduce the rotation speed to 500r / min and continue stirring for 30min, then repeat the operation once;

[0091] 2) Grinding the bamboo fibers to 40 meshes, ad...

Embodiment 2

[0094] Embodiment 2: a kind of powder material for coating of high wear resistance automobile wheel hub, its components are calculated by weight percentage: 28.5% of epoxy resin, 34% of modified carboxyl-terminated saturated polyester resin, 0.5% of curing agent, Wear-resistant powder 25%, titanium dioxide 5%, quartz powder 6%, leveling agent 1%.

[0095] The curing agent is hydroxyalkylamide.

[0096] Wear-resistant powder is Al2O3.

[0097] The preparation method of described modified carboxyl-terminated saturated polyester resin is:

[0098] 1) Add 1.5 times its weight and 75% concentrated sulfuric acid to the diatomite powder, filter after stirring, dry the filter residue and calcinate at 600°C for 35min to obtain refined diatomite powder; wherein, the stirring operation is Stir at 1200r / min for 10min, then reduce the rotation speed to 550r / min and continue stirring for 35min, then repeat the operation once;

[0099] 2) Grind the bamboo fiber to 50 mesh, add 1.5 times t...

Embodiment 3

[0102] Embodiment 3: A kind of powder material for coating of high wear resistance automobile wheel hub, its components are calculated by weight percentage: 30% of epoxy resin, 30% of modified carboxyl-terminated saturated polyester resin, 0.5% of curing agent, Wear-resistant powder 23.5%, titanium dioxide 8%, quartz powder 7%, leveling agent 1%.

[0103] The curing agent is hydroxyalkylamide.

[0104] Wear-resistant powder is Al2O3.

[0105] The preparation method of modified carboxyl-terminated saturated polyester resin is:

[0106] 1) Add 1.5 times its weight and 80% concentrated sulfuric acid to the diatomite powder, filter after stirring, dry the filter residue and calcinate at 800°C for 40min to obtain refined diatomite powder; wherein, the stirring operation is Stir at 1500r / min for 10min, then reduce the rotation speed to 600r / min and continue stirring for 40min, then repeat the operation once;

[0107] 2) Grinding the bamboo fibers to 80 mesh, adding 2 times the vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com