Steel-wire-rope-suspended maintenance machine

A wire rope and winch technology, applied in the field of wire rope maintenance, can solve the problems of uneven descaling and grease application, waste of manpower and material resources, easy injury of hands and people, etc., and achieve the effect of improving operational efficiency, saving costs, and long working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

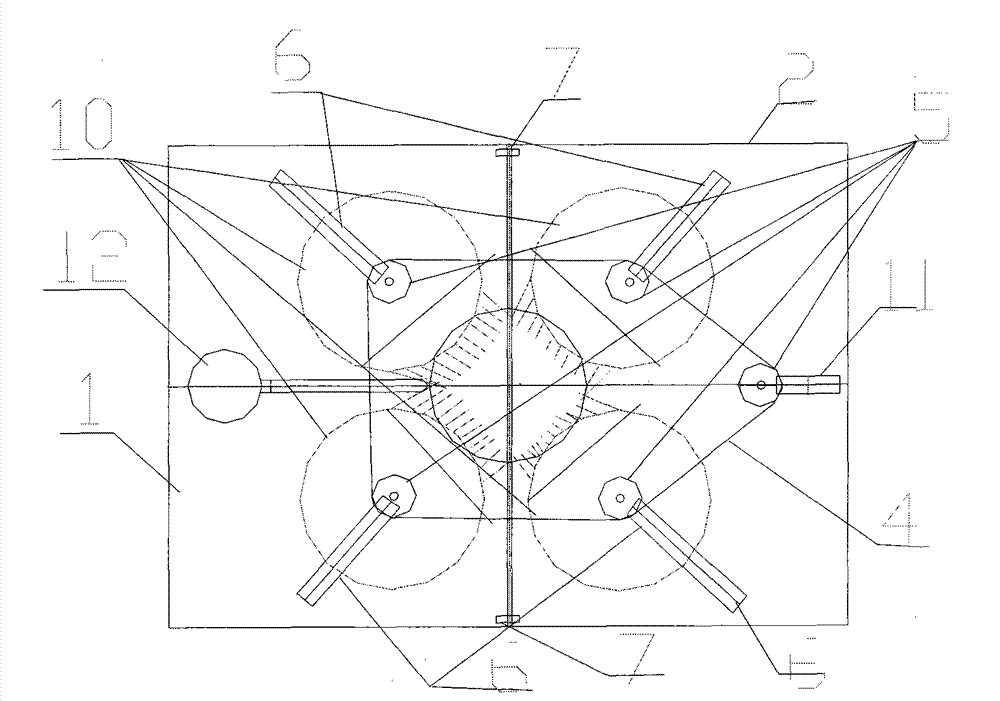

[0017] The present invention as Figure 1 to Figure 2 As shown, the wire rope suspension maintenance machine includes a left box 1, a right box 2, a wire rope guide wheel oil seal 3, a sprocket 5, a chain 4, a sprocket adjustment shaft 6, a lock 7, a lock lanyard 8, front and back Electric winch 9, brush roller 10, motor 11, oil pump 12, oil filling pipe 13, upper oil tank 14, lower oil tank 15, filter oil return pipe 16, support 17, it is characterized in that: the maintenance machine frame is composed of folding The rectangular or cylindrical or special-shaped lock 7 is connected to the left box 1 and the right box 2. The left and right boxes are opened, and the wire rope is sleeved in the two semicircular wire rope guide wheel oil seals 3. When the left and right boxes are closed, the lock 7 is locked. Hold the steel wire rope 18, the steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com